Industrial robot clamping part

A technology for industrial robots and clamping components, applied in chucks, manipulators, manufacturing tools, etc., can solve the problems of falling items, insufficient friction of irregular items, etc., and achieve increased stability, wide application range, and stable clamping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

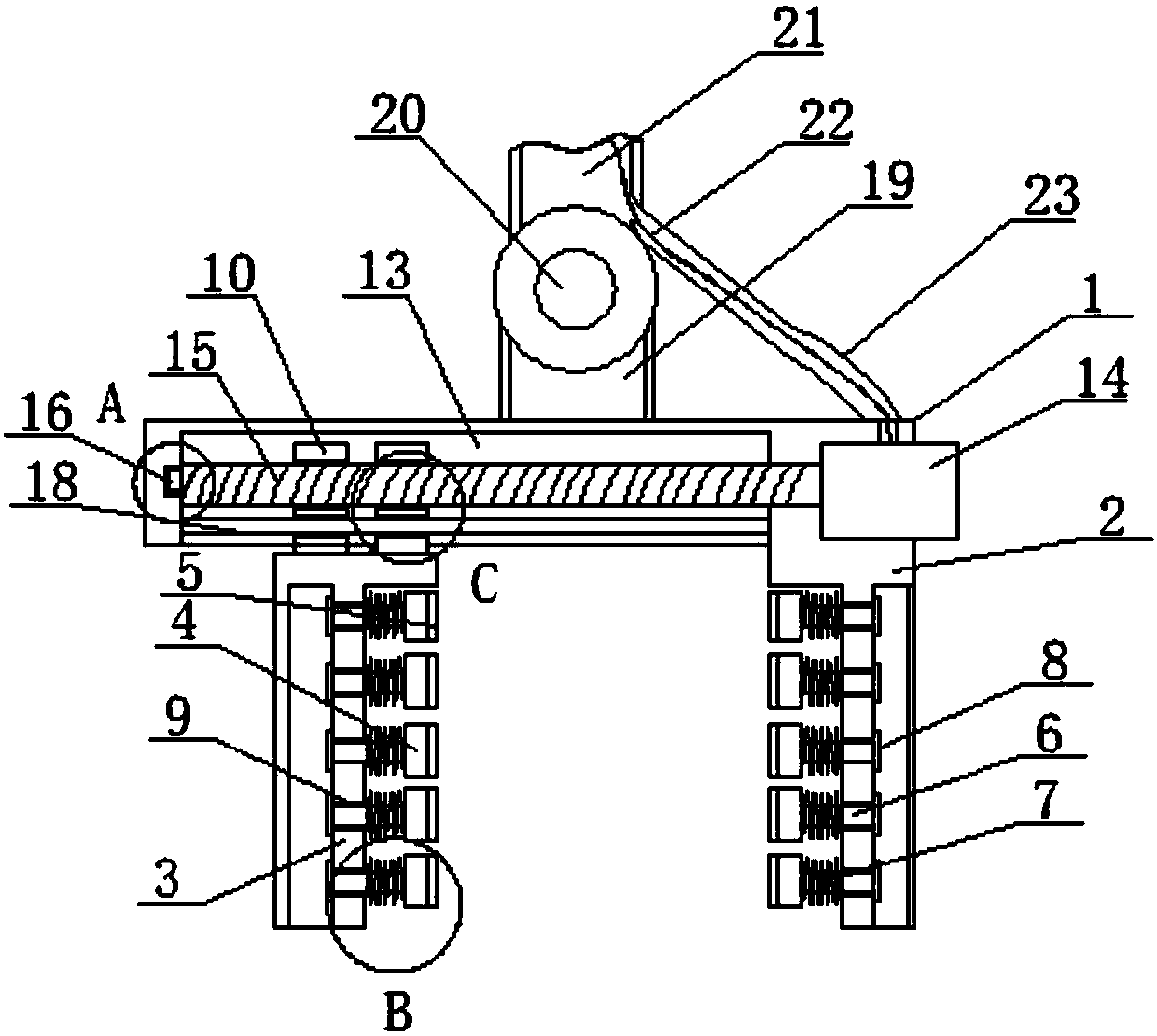

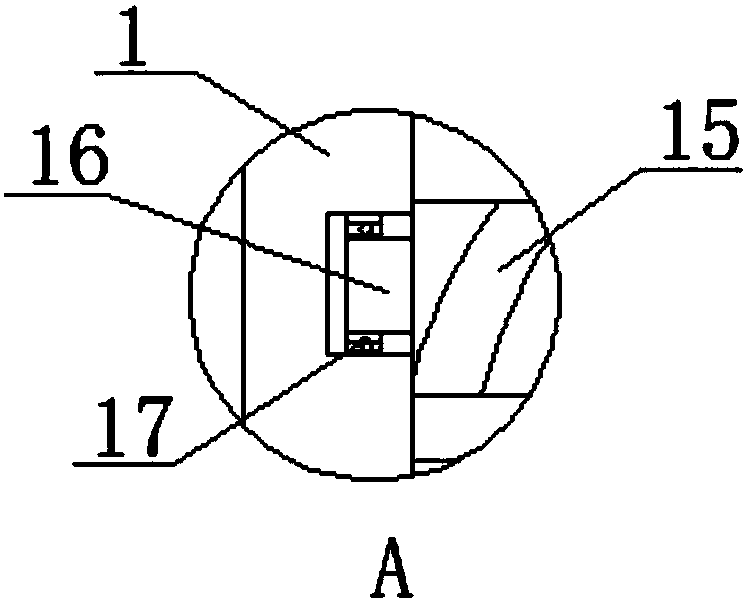

[0024] see Figure 1-Figure 5 As shown, a clamping part of an industrial robot includes a clamping beam 1, a fixed claw 2, a moving claw 3 and a connecting rod 19. One end of the clamping beam 1 is connected to the fixed claw 2, and the fixed claw 2 is matched with the movable claw 3. Items are grasped, and one end of the clamping beam 1 is connected to the moving claw 3, and the moving claw 3 can move freely in the horizontal direction to adapt to the grabbing of objects of different sizes. The moving claw 3 is provided with a plurality of through holes 9 for connecting multiple A floating block 4, a connecting rod 6 is arranged in the through hole 9, and the connecting rod 6 is used to connect the floating block 4 and cooperate with the limiting block 8 to limit the floating block 4, and one side of the floating block 4 is connected to the anti-slip block 5, and the anti-slip block 5 Increase the friction to make the clamping more stable. The connecting rod 6 is connected to...

Embodiment 2

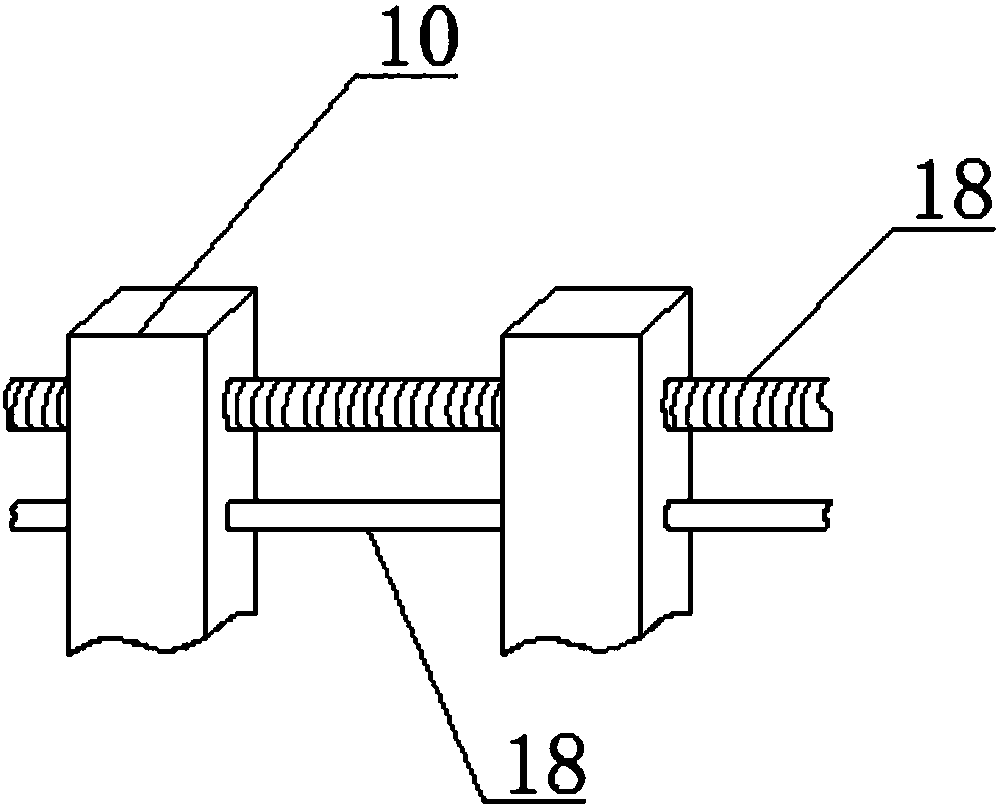

[0026] In addition, refer to Figure 1-Figure 5 , based on the above-mentioned embodiment, a plurality of through holes 9 are set on the movable claw 3, the fixed claw 2 and the movable claw 3 are set in the same way, and the fixed claw 2 and the movable claw 3 are symmetrically arranged, so that the fixed claw 2 and the movable claw 3 can be multiple The floating block 4 is set, and the clamp can bear the force symmetrically, and the clamped object is more stable. A matching anti-skid block 5 is set on one side of the floating block 4, and multiple floating blocks 4 are arranged on the same horizontal line, so that the floating block 4 can be evenly supported. force, the diameter of the limiting block 8 is greater than the diameter of the through hole 9, the connecting rod 6 is flexibly connected to the through hole 9, so that the limiting block 8 will not fall off, the connecting rod 6 can move freely, and the sliding block 10 is symmetrically arranged on the moving claw 3 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com