Safe mixer car for cement

A mixer truck and cement technology, applied in vehicle safety arrangements, vehicle parts, concrete transportation, etc., can solve major traffic accidents, no protective boards, electric vehicles and pedestrians rolling and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

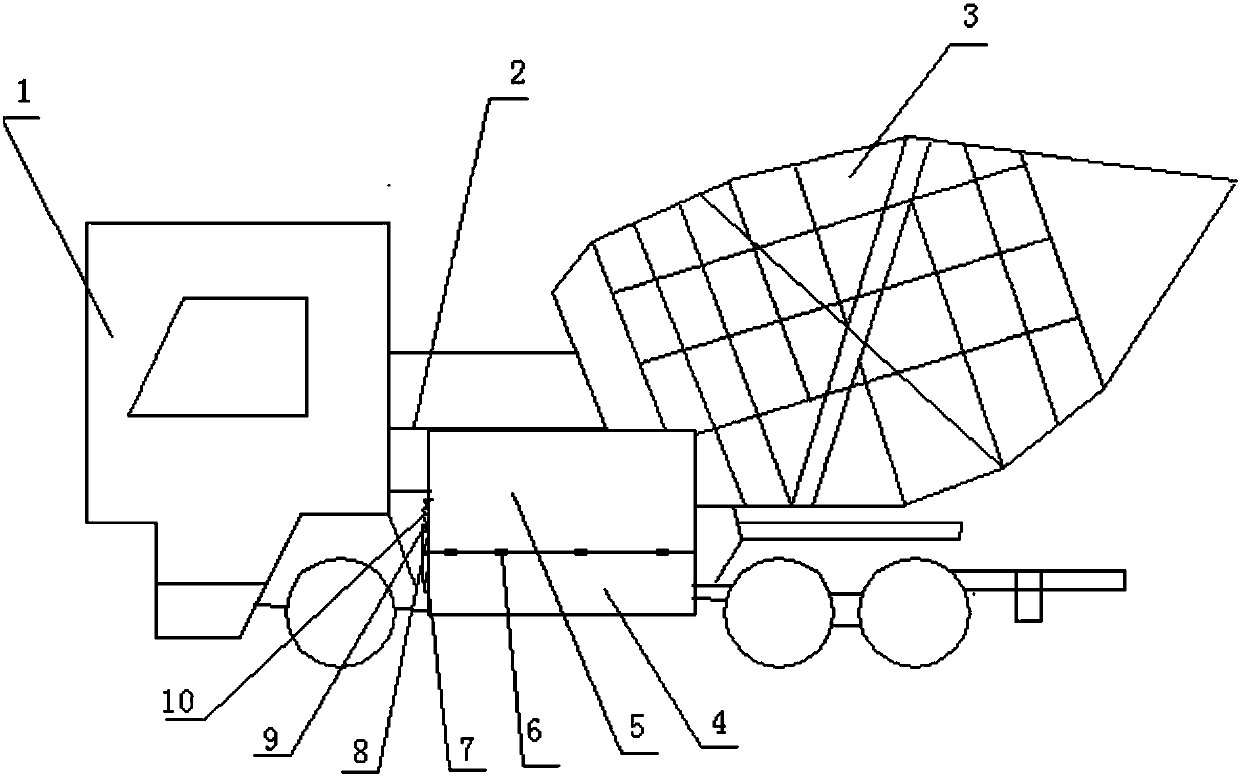

[0011] Such as figure 1 As shown, a safety cement mixer truck includes front and rear wheels, a driver's cab 1 and a frame 2 on which a cement mixing tank 3 is installed, and protective plates are installed on both sides of the frame 2 between the front and rear wheels. 6 consists of an upper guard plate 5 and a lower guard plate 4 hinged together. The lower edge of the lower protective plate 4 is lower than the line height of the front and rear wheel centers.

[0012] Such as figure 1 As shown, the side of the upper protective plate 5 is equipped with a through upper casing 8, the side of the lower protective plate 4 is equipped with a lower casing 7 corresponding to the upper casing 8, and a chain 10 is also installed above the upper casing 8. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com