A method for adjusting the step difference of glass observation window on the side wall of a high-speed wind tunnel

A glass observation window and high-speed wind tunnel technology, which is applied in the testing of machines/structural components, instruments, measuring devices, etc., can solve the problem that the glass pressing force and step difference cannot be guaranteed at the same time, and the roundness and taper of the installation surface are prone to overshoot Poor, contact or point contact and other problems, to avoid the glass from being crushed, shorten the cycle, and enhance the supporting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The high-speed wind tunnel side wall glass observation window step adjustment method of the present invention is applied in a high-speed wind tunnel of the order of 2 meters. The diameter of the observation window of the high-speed wind tunnel is Φ850mm. During the wind tunnel test, the glass of the observation window bears The maximum pressure difference is 1kg / cm 2 , the maximum pressure is about 5500kg.

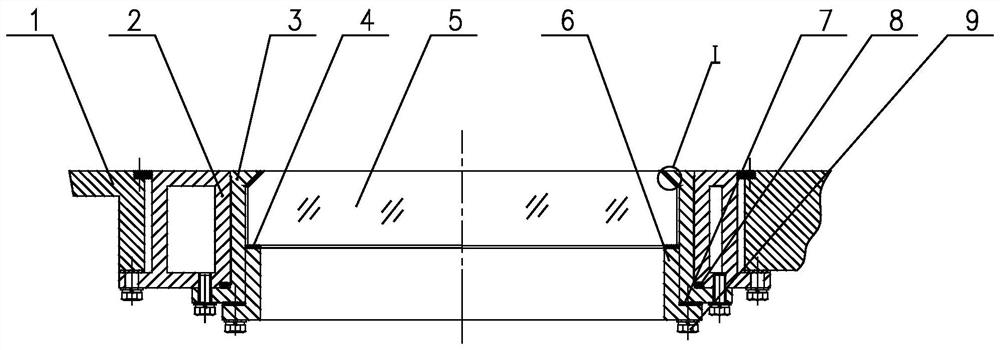

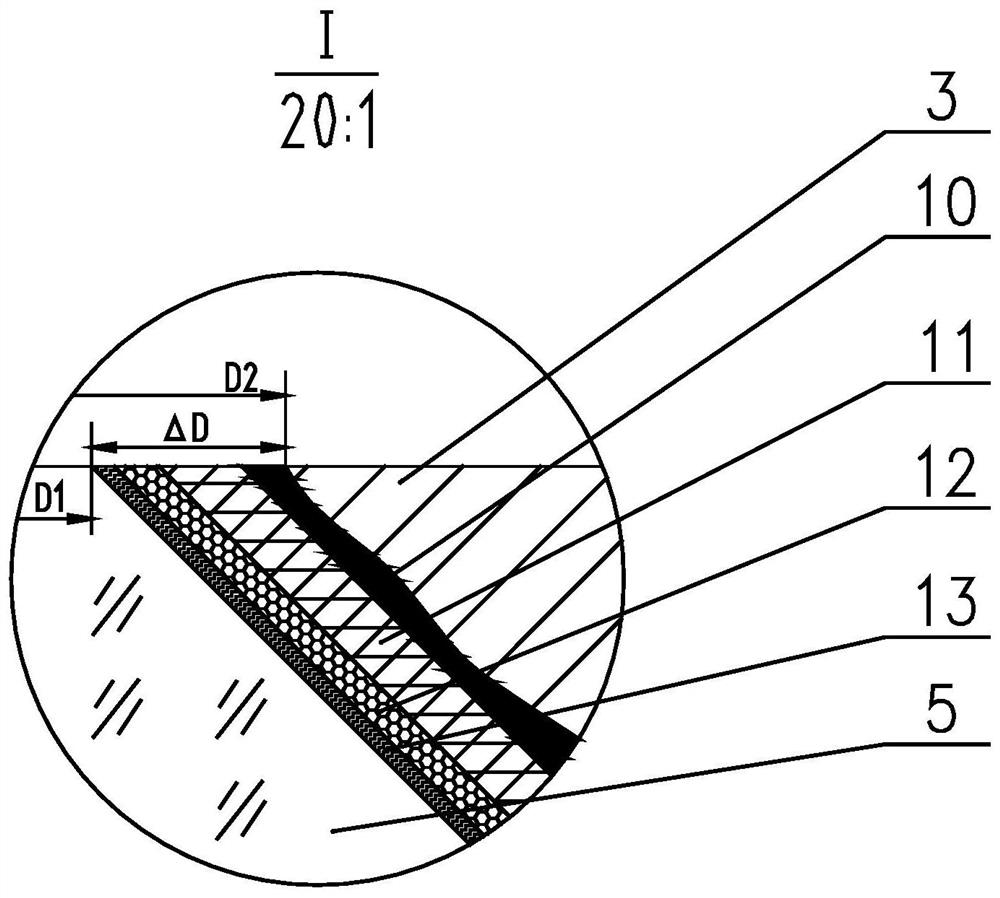

[0031] Such as figure 1 As shown, a metal square steel window 2 is installed on the side wall 1 of the wind tunnel, and a round steel window 3 is fixed inside the square steel window 2, and the pressing window 6 presses the glass 5 on the round steel window 3 from the outside of the wind tunnel to the inside. , rubber pad I4 is installed on the contact surface between the press window 6 and the glass 5, rubber pad II7 is installed on the contact surface between the press window 6 and the round steel window 3, and a rubber pad II7 is installed on the contact surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com