A butt joint for aircraft vacuum wastewater system and ground sewage vehicle

A technology for butt joints and waste water, which is applied in the aviation field, can solve problems such as large environmental impact, inconvenient operation, and inconvenient installation, and achieve the effects of simple and convenient operation, reliable performance, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below.

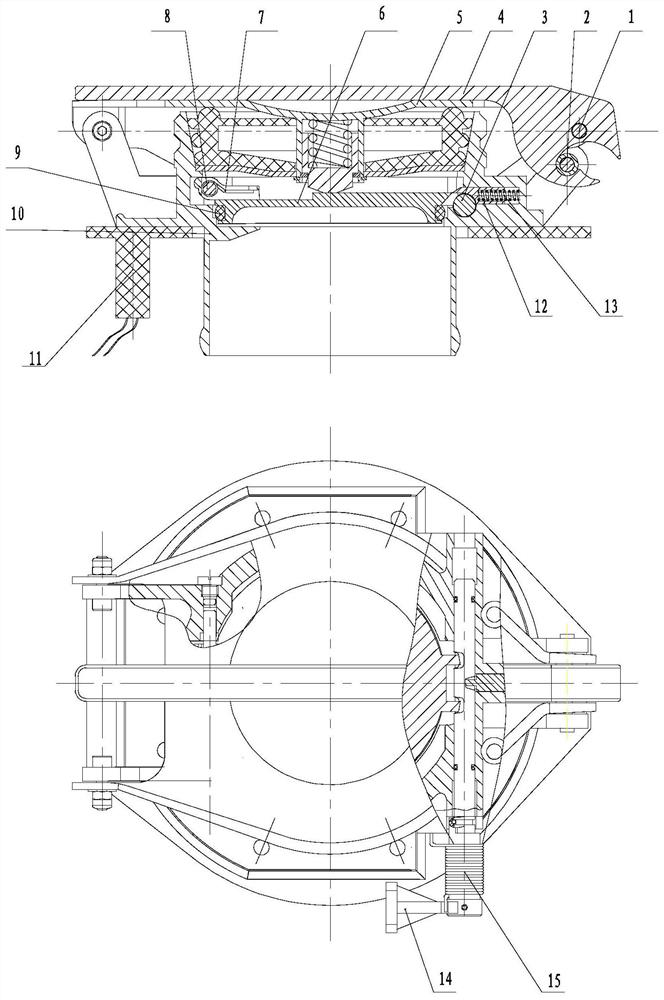

[0014] see figure 1 , the sewage joint of the present invention is mainly composed of 1 outer cover opening pin, 2 handle rotation pins, 3 inner cover springs, 4 inner cover opening shafts, 5 handles, 6 outer cover assemblies, 7 inner covers, 8 torsion springs, 9 inner Cover rotating shaft, 10 sealing ring, 11 housing components, 12 heating pads, 13 inner cover pins, 14 opening handles, 15 handle twists and the like. The outer cover opening pin (1) is installed on the housing assembly (10) to lock the handle (4) to prevent the outer cover assembly (5) from accidentally opening; the handle rotation pin (2) connects the handle (4) to the outer The cover assembly (5) is connected together by riveting, but the handle should rotate flexibly after riveting; the inner cover is connected with the shell assembly (10) through the inner cover shaft (8) and is equipped with a torsion spring (7), which is used as th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap