Pin disk friction tester

A friction testing machine and pin-disc technology, which is applied in the direction of mechanical devices, measuring devices, instruments, etc., can solve the problems of affecting observation, pressure cannot be adjusted, jumping, etc., and achieve the effect of improving utilization rate, avoiding jumping, and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

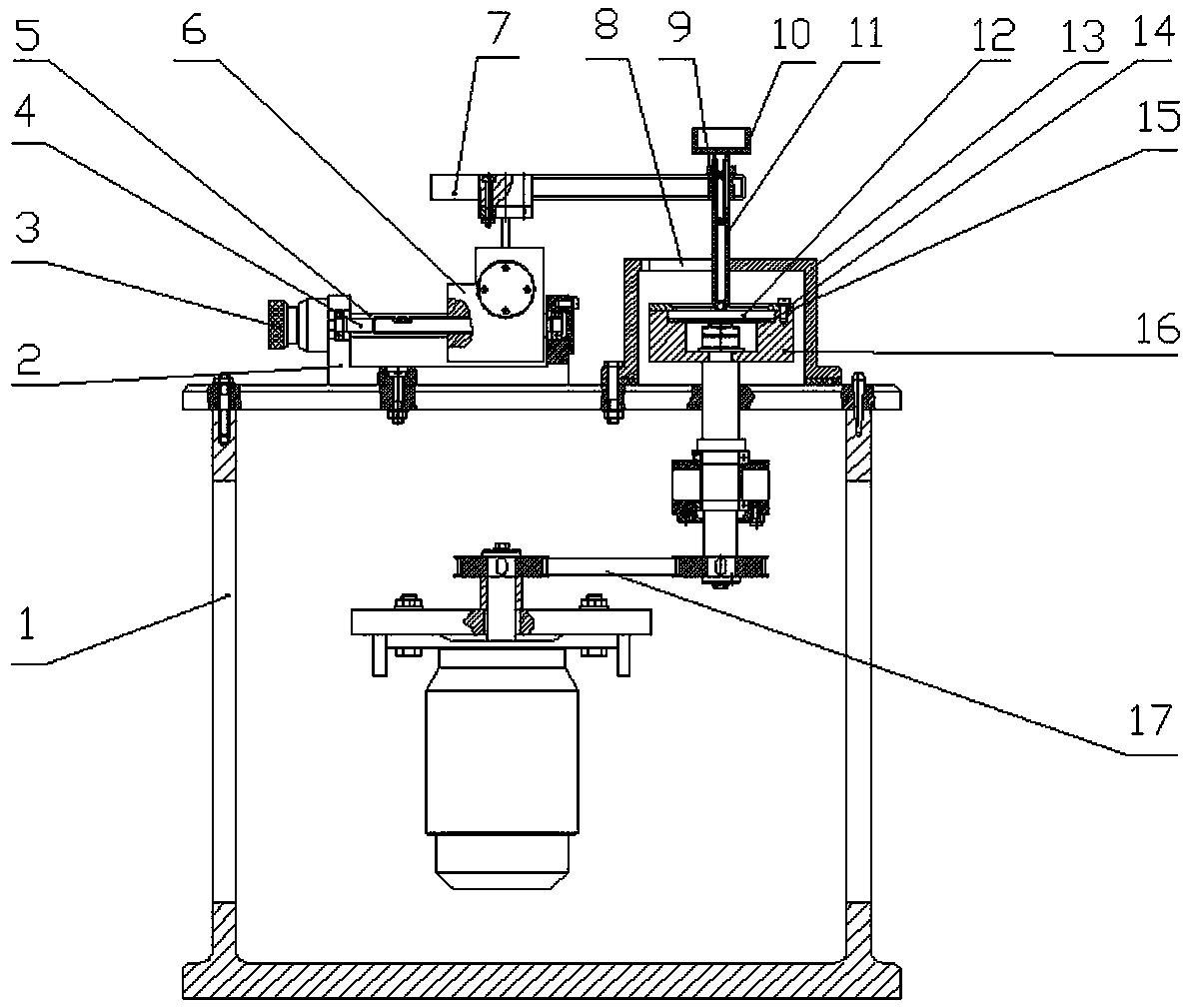

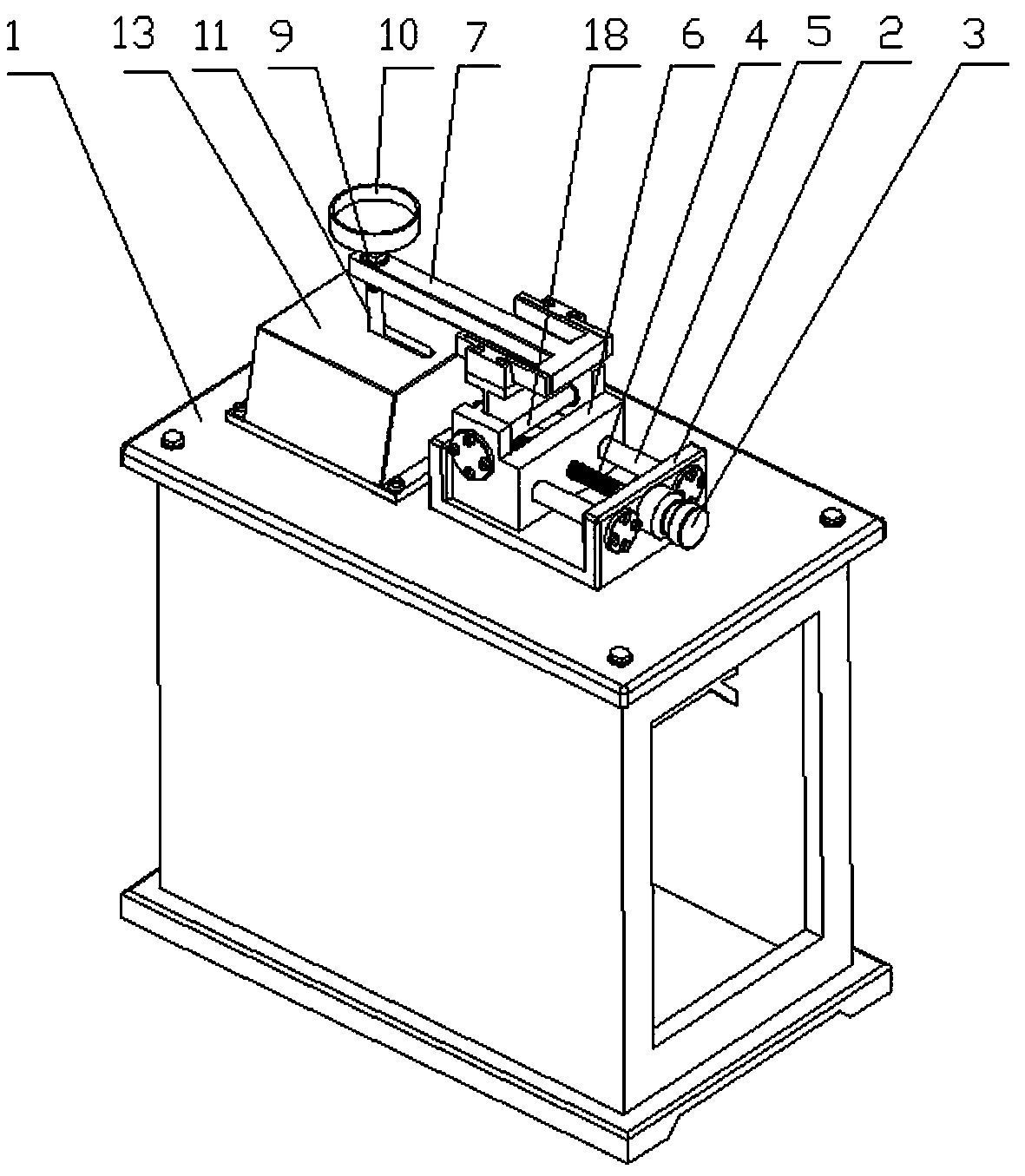

[0022] like Figure 1 to Figure 3 Shown, a kind of pin-on-disk friction testing machine of the present invention comprises a rectangular hollow test bench 1, is provided with on the table top of test bench 1 the friction disk 12 and friction pin 11 that are used to carry out friction test, the pin of friction pin 11 The friction test was carried out by contacting the head part with the disc surface of the friction disc 12 . During the friction test, the friction disc 12 is driven to rotate by the driving device 17 arranged inside the test bench 1, and the friction pin 11 remains stationary. The pressure and position adjustment device between the discs 12.

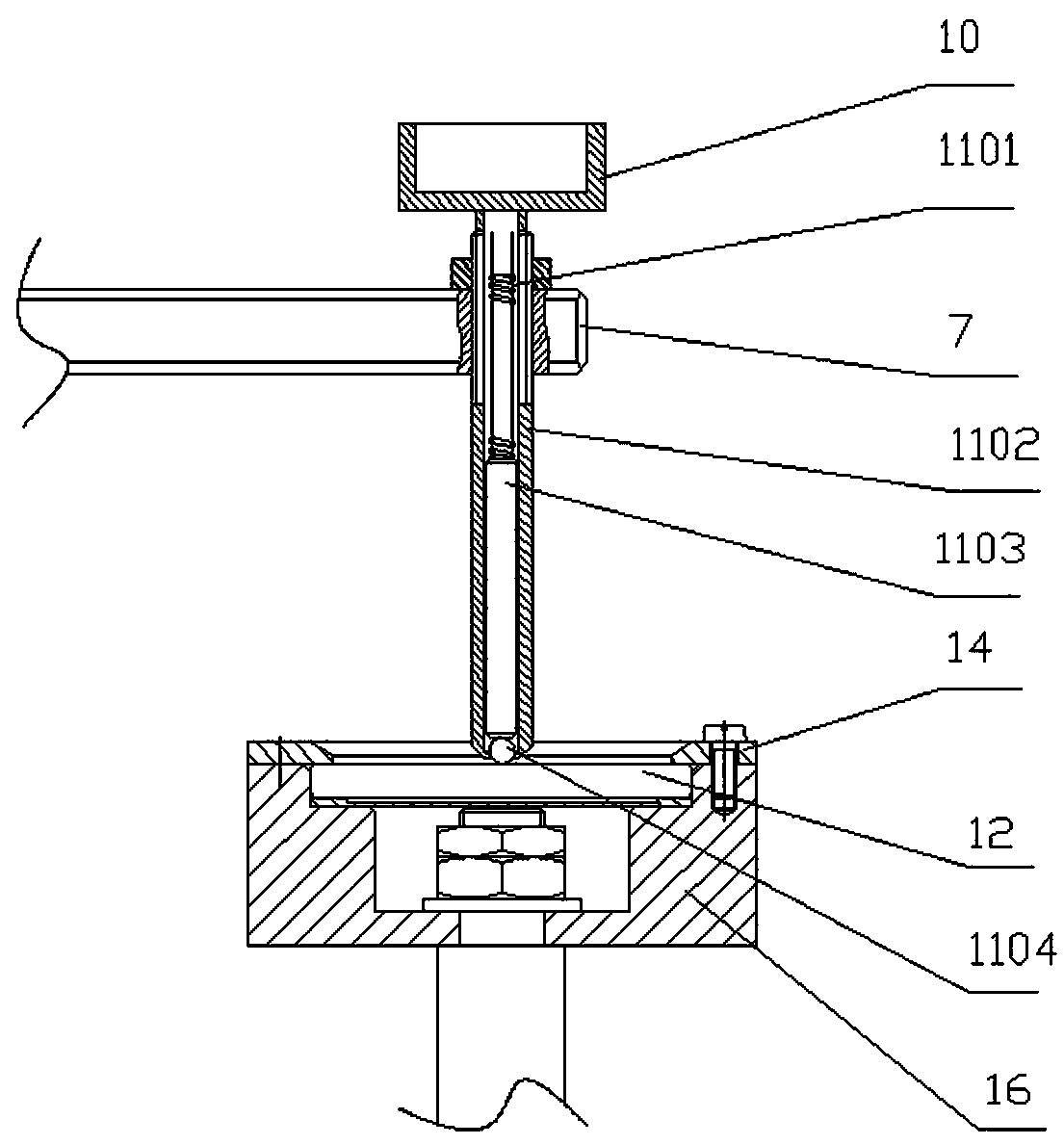

[0023] In this embodiment, the friction disc 12 is fixedly arranged in the holder, and the holder includes a lower end cover 16 with a step and a bolt that is fixedly connected with the lower end cover 16 and is used to press the friction disc 12 tightly on the step of the lower end cover 16. The annular upper end cover 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com