Bending machine for processing tube joints

A technology for bending machines and pipe sections, applied in the field of bending machines, can solve the problems of long time-consuming joints of pipe sections and the inability to guarantee full sealing at the joints, and achieve the effects of reducing manpower and material resources, enhancing brightness and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

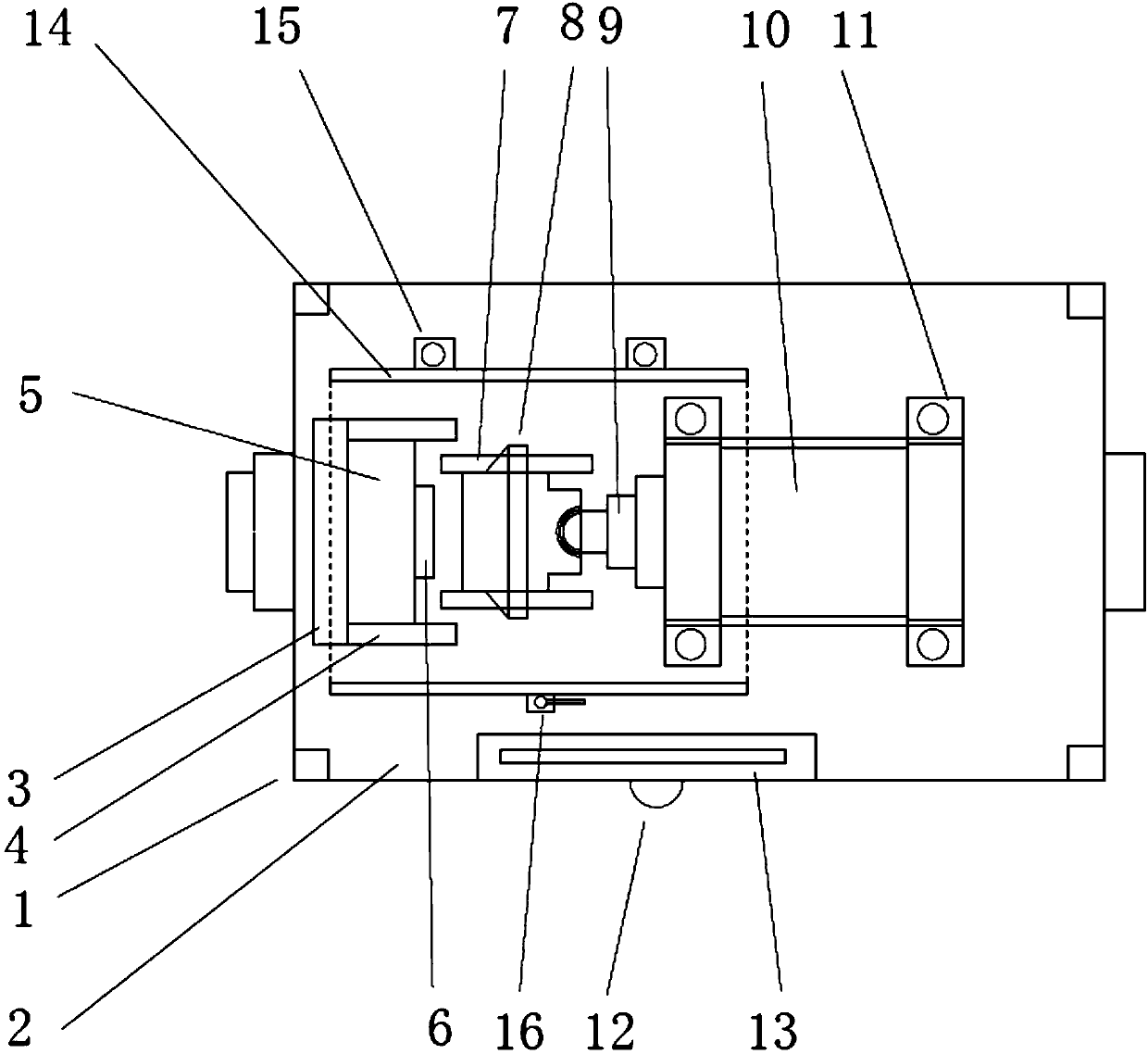

[0015] Such as figure 1 As shown, the present invention provides a bending machine for processing pipe joints, including a support rod 1, a base 2 is provided on the upper part of the support rod 1, a baffle 3 is provided on one side of the upper surface of the base 2, and a baffle 3 is provided at both ends. There are laterally placed side plates 4, clamping blocks 5 are arranged between the two side plates 4, and the right side of the clamping block 5 is provided with an annular belt 6. The right side of the annular belt 6 is provided with two transverse guide rails 7 placed front and rear, A briquetting block 8 is arranged between the two transverse guide rails 7, a push block 9 is provided on the right side of the briquetting block 8, an oil cylinder 10 is provided on the right side of the push block 9, an oil cylinder base 11 is provided at the bottom of the oil cylinder 10, and a lamp holder 12 is connected to the side of the base 2, A light bulb 13 is provided on the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com