Grille-type flocculating settling device and construction method thereof

A settling device and construction method technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of increasing flocculation time, increasing floc fragmentation, and untimely changes, saving investment and operating costs, and reducing floor space. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

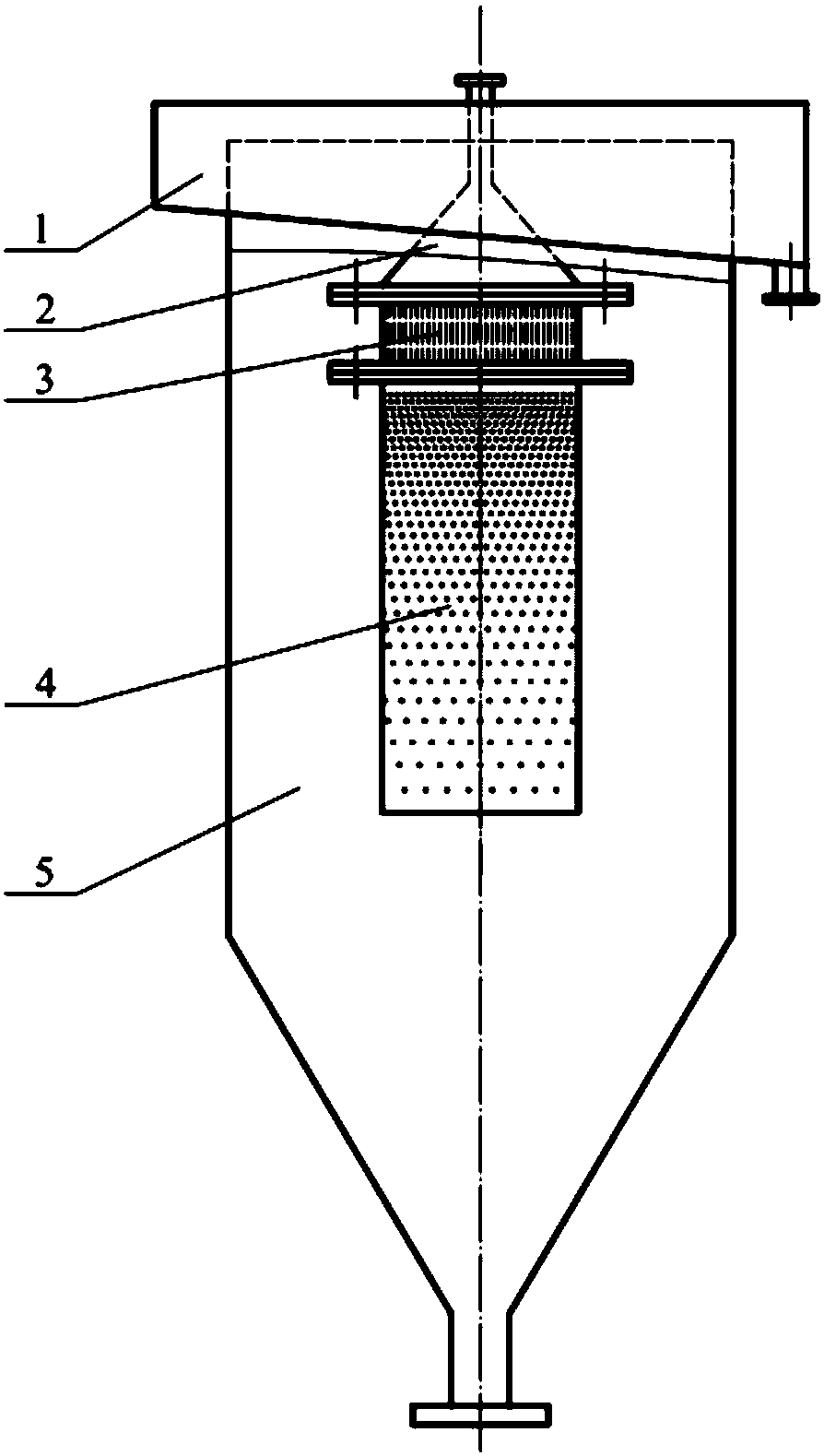

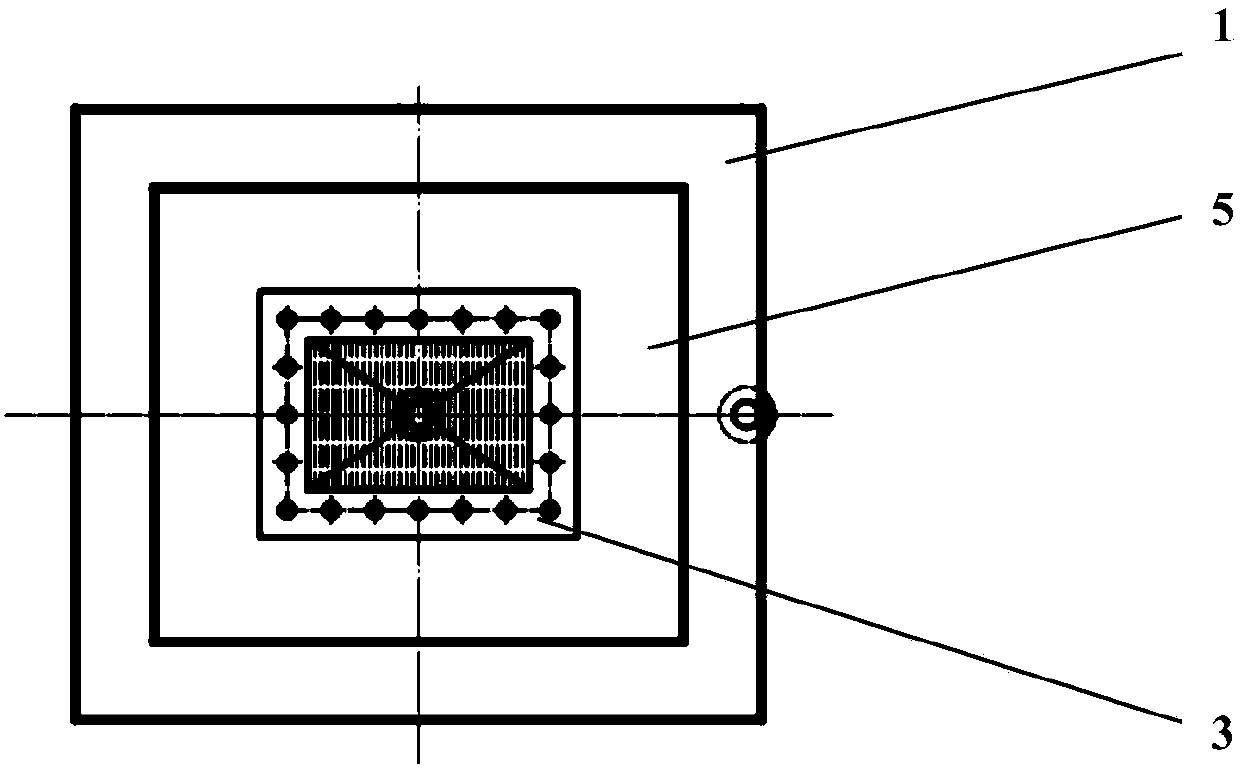

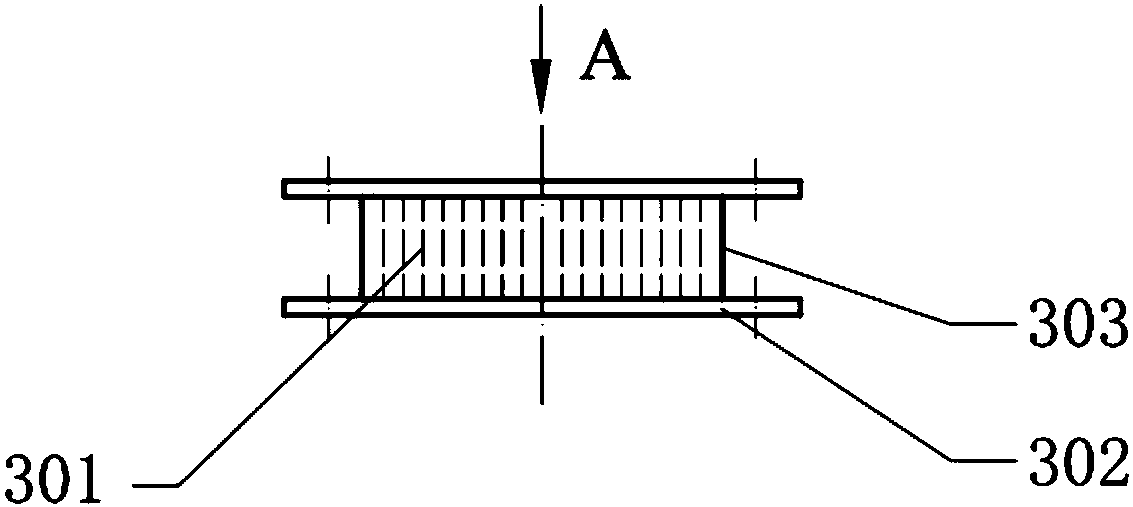

[0026] combined with Figure 1-7 , a grid-type flocculation settling device and its construction method, comprising a settling tank 5, a flocculation unit is arranged in the center of the settling tank 5, the overflow water collection tank 1 is externally connected to the top of the settling tank 5, and the flocculation unit includes a water distribution unit Funnel 2, water distribution grid 3, flocculation grid 4, the water distribution funnel 2, water distribution grid 3 and flocculation grid 4 are connected in series from top to bottom.

[0027] As a preferred embodiment of this embodiment, the flocculation grid 4 is composed of a grid bar 403 with a circular or polygonal cross section, and the diameter of the grid bar 403 or the diameter (d) of its circumscribed circle is not greater than 10mm. The grid bars 403 are arranged row by row from top to bottom, wherein the center-to-center distance of the first row of grid bars (1 1 ) is set to d+5~10mm, starting from the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com