Down-flow type fluidized bed flocculating settling device

A settling device and down-flow technology, applied in the field of down-flow fluidized bed flocculation and settling devices, can solve problems such as floc fragmentation, and achieve the effects of reducing fragmentation, saving investment and operating costs, and reducing equipment footprint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

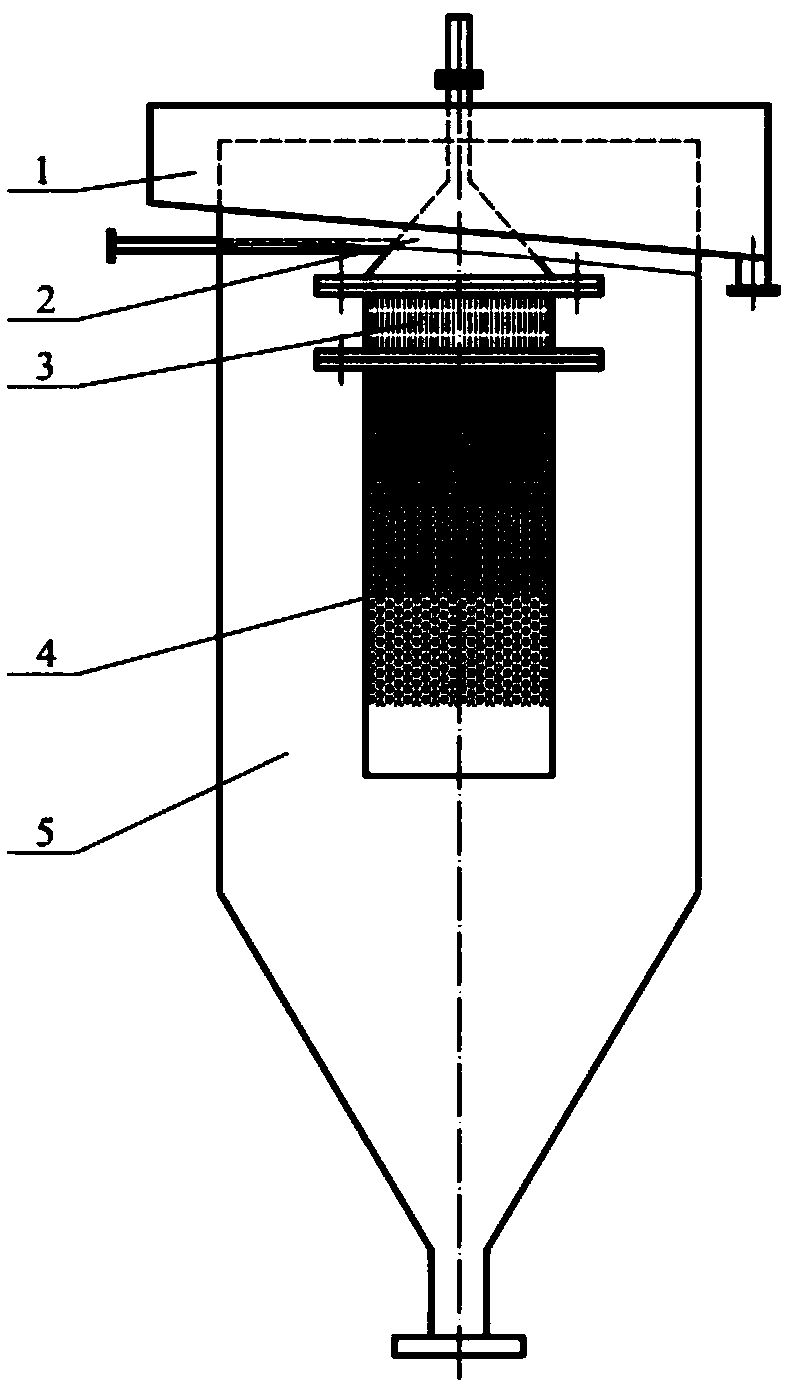

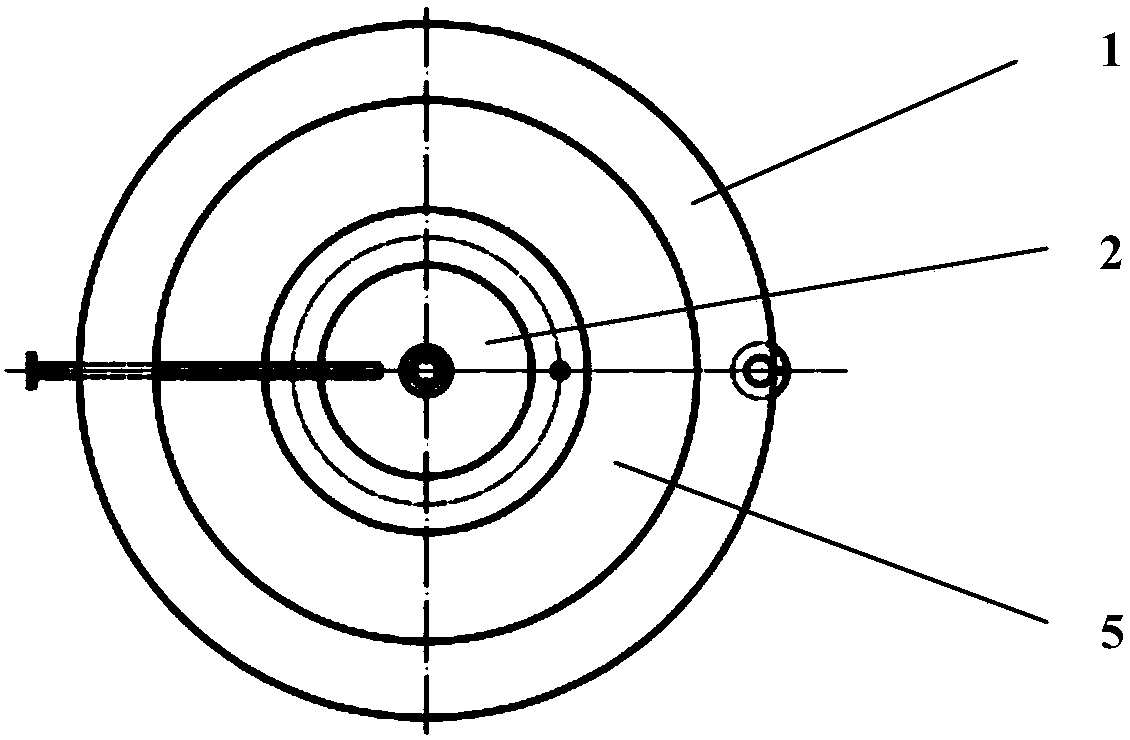

[0028] combined with Figure 1-8 , a downflow fluidized bed flocculation settling device, including a flocculation unit, a settling tank 5 and an overflow water collection tank 1, the flocculation unit is arranged in the center of the settling tank 5, and the top of the settling tank 5 is connected to the overflow water collection tank 1 ;

[0029] The flocculation unit includes a water distribution funnel 2, a water distribution grid 3 and a downflow fluidized flocculation reaction bed 4, and the water distribution funnel 2, a water distribution grid 3 and a downflow fluidization flocculation reaction bed 4 Set in series from top to bottom.

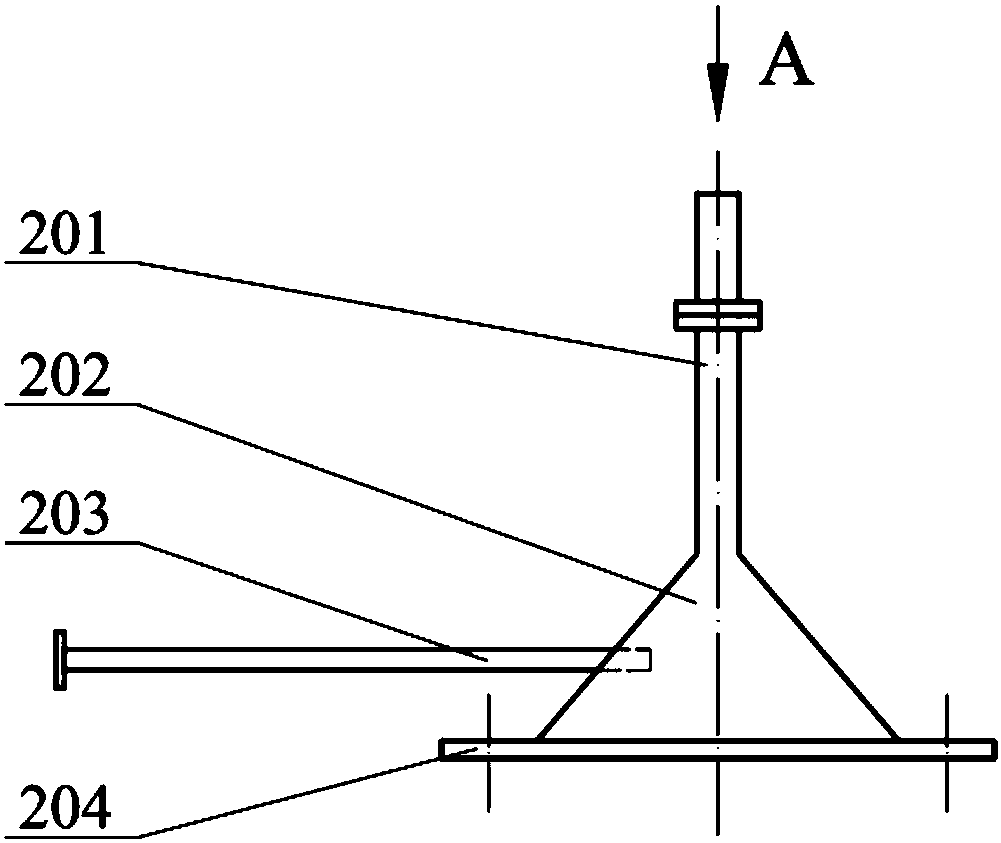

[0030] As a preferred embodiment of this embodiment, the water distribution funnel 2 includes an inverted funnel 202, the bottom of the inverted funnel 202 is provided with a flange 204, and the top is provided with an exhaust pipe 201, and the water distribution funnel 2 One side is also provided with feed pipe 203 .

[0031] As a pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com