Weaving method of 360° omnidirectional elastic knitted fabric and a circular knitting machine

A circular knitting machine, omni-directional technology, applied in weft knitting, knitting, textiles and papermaking, etc., can solve the problems of poor elasticity and recovery of terry fabrics, so as to slow down the resistance of yarn feeding, reduce the defect of anti-filament breaking, The effect of reducing the head break rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

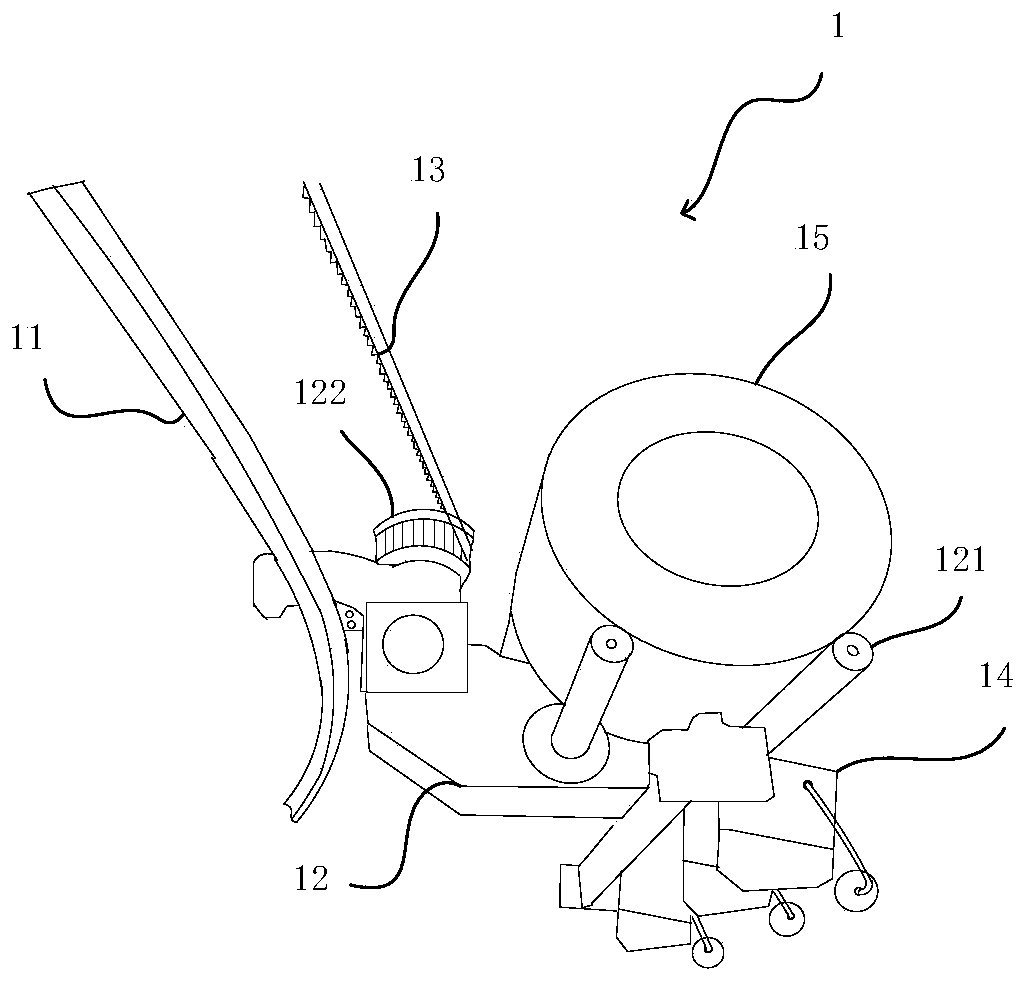

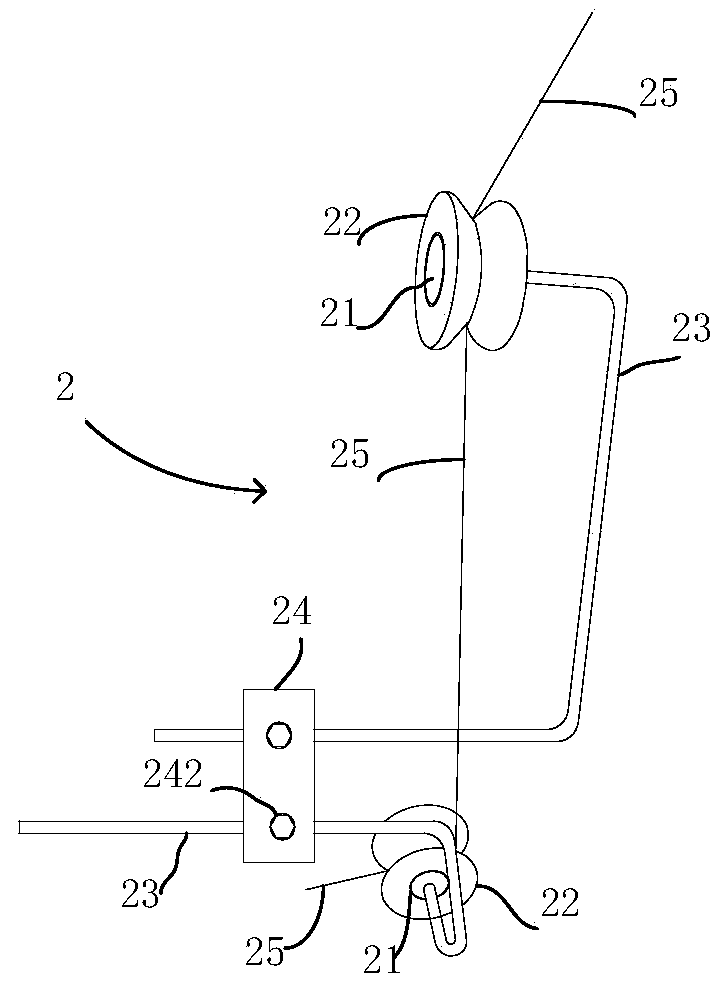

[0038] This embodiment provides a circular knitting machine for producing 360° omnidirectional elastic knitting fabrics. A spandex yarn delivery system 1 is set on the single-jersey circular knitting machine, and a spandex yarn guide 2, a loop-forming and tucking cam 3 are improved, and Circle knitted triangle4.

[0039] Such as figure 1 As shown, the spandex yarn feeding system 1 includes a circular fixing frame 11 (only a part is shown in the figure, and the remaining parts have the same structure), a spandex yarn feeding device 12, a yarn feeding timing belt 13 and a spandex yarn breaking automatic stop device 14. Circular fixed frame 11 is arranged on the periphery of the creel of circular knitting machine, and several spandex yarn feeders 12 are arranged at equal intervals on circular fixed frame 11, are used for conveying spandex yarn, and at least two spandex yarn feeders 12 are arranged in parallel The wire feeding roller 121 is used to place the spandex bobbin 15 bet...

Embodiment 2

[0051] This embodiment provides a method for knitting a 360° omni-directional elastic knitted fabric. The circular knitting machine provided in Embodiment 1 is used to weave a knitting course every three ways. As a loop forming system, it is divided into loop yarn, surface yarn, Ground yarn, loop yarn is 18.2tex compact spun yarn, loop length is 175mm / 100 buttons, surface yarn is 14.6tex compact spun yarn, loop length is 400mm / 100 buttons, ground yarn is 33dtex spandex yarn, loop length is 128mm / 100 deduction.

[0052] The weaving process is as follows:

[0053] The first way: the A-heel machine needle follows the needle-lifting triangle and the sinker to weave the gray cloth lining yarn as the loop yarn;

[0054] The second way: all the needles knit the surface yarn of the triangle knitting without knitting, and the loop yarn loops can be removed when knitting the triangle bending yarn, and the surface yarn loops can not be looped;

[0055] The third way: All the needles a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com