Weft-insertion yarn carrier device for flat knitting machine

A technology for knitting flat knitting machines and yarn feeders, used in knitting, weft knitting, textiles and papermaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

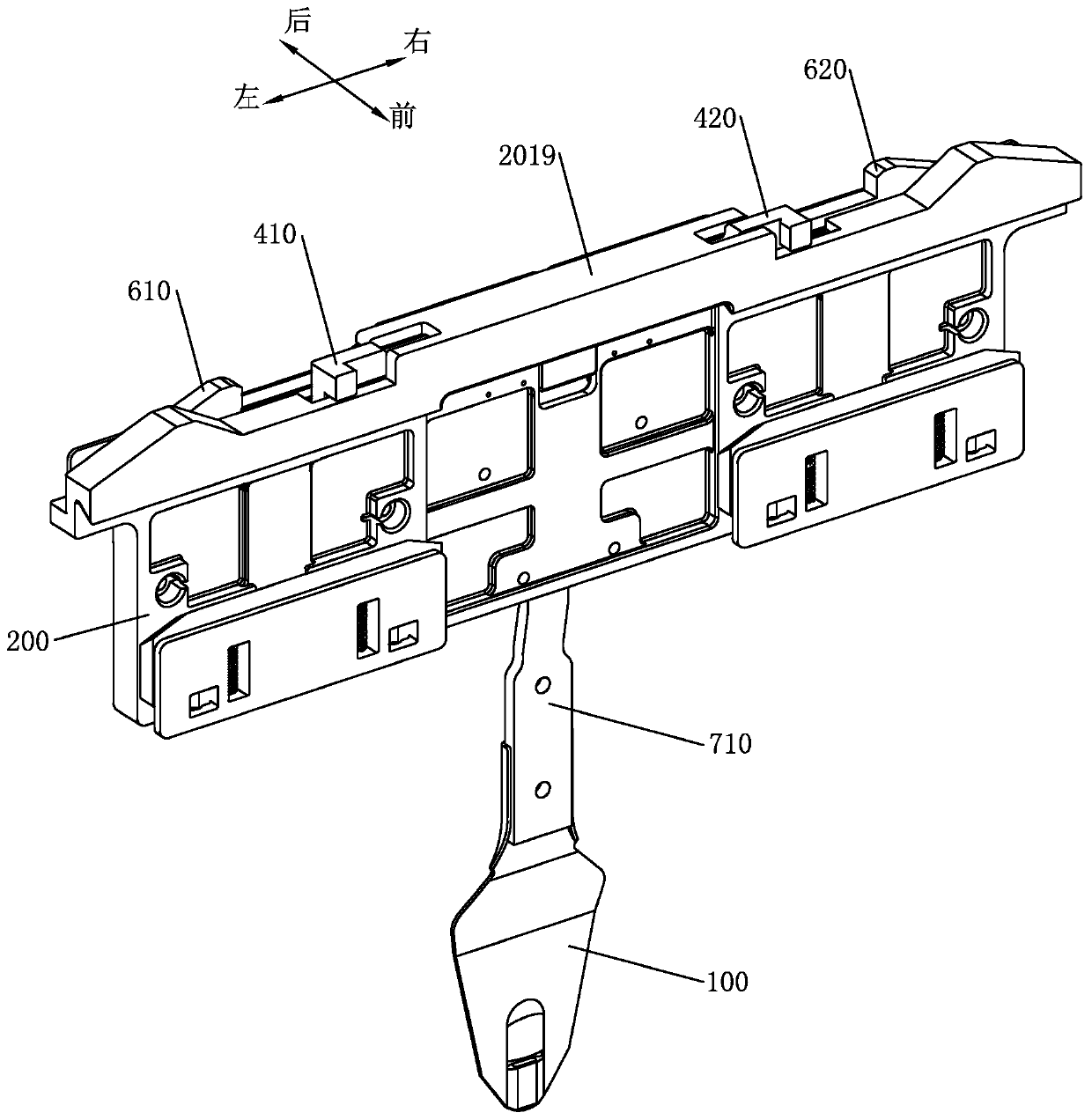

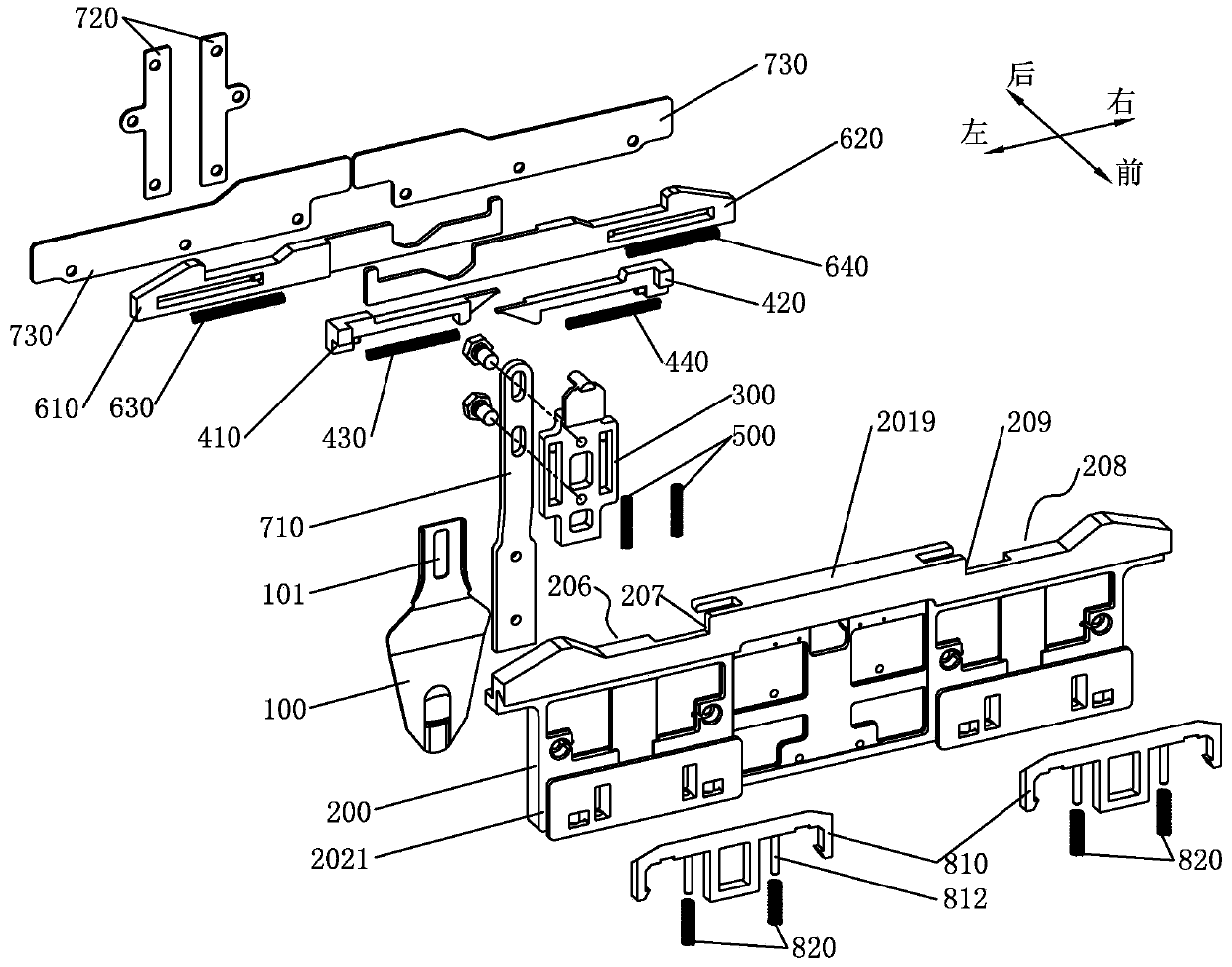

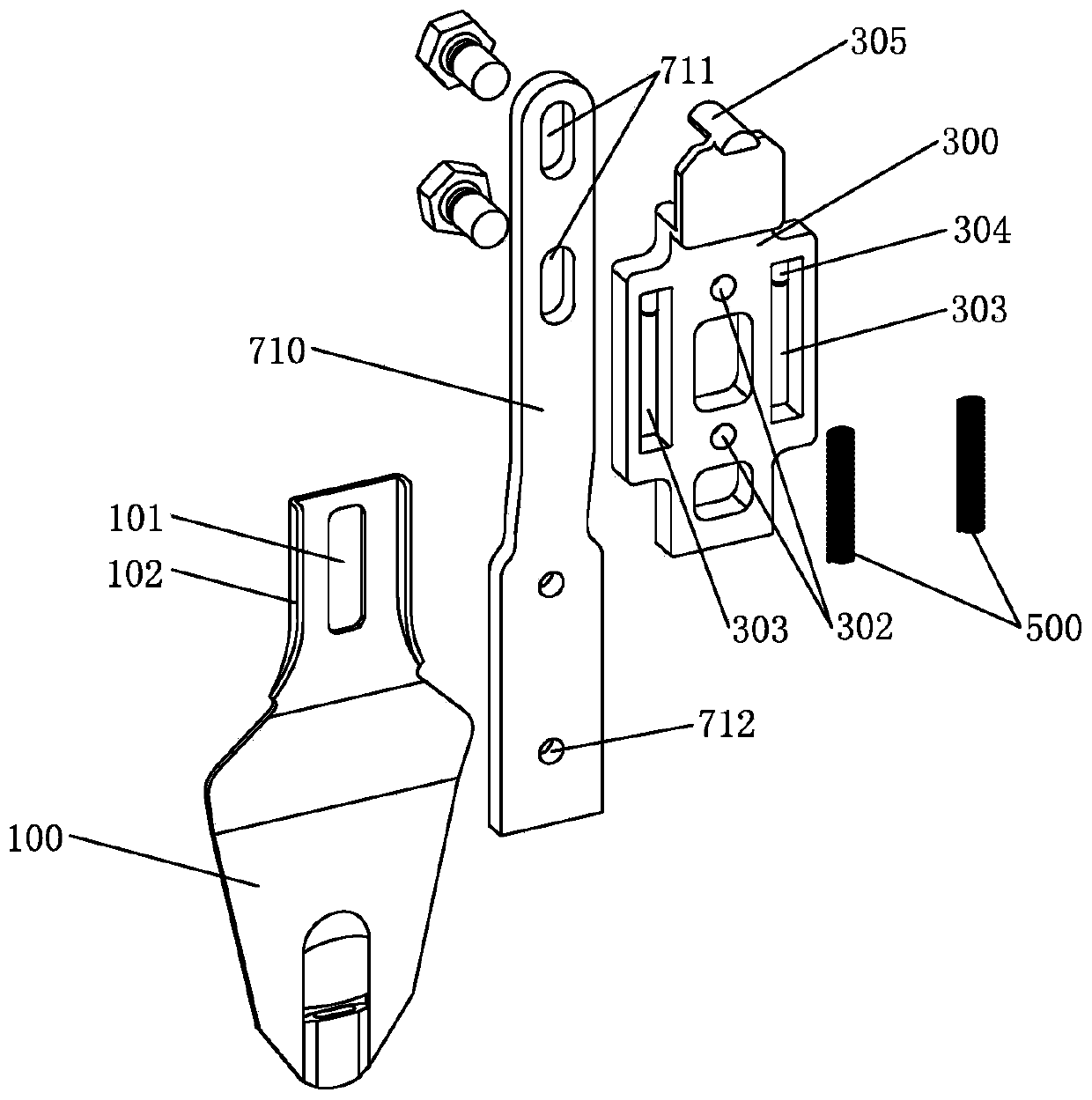

[0048] Such as figure 1 , figure 2 As shown, a weft inserted yarn feeder device provided by Embodiment 1 of the present invention includes a yarn feeder 100 and a yarn feeder seat 200. The weft inserted yarn feeder device also includes a linkage seat 300, a driving mechanism, a resetting member and an auxiliary resetting mechanism. The linkage base 300 is arranged on the yarn feeder base 200 to move up and down, the yarn feeder 100 is connected to the linkage base 300, and the driving mechanism is arranged on the yarn feeder base 200 so as to move left and right and can drive the linkage base 300 to move down. Between the linkage base 300 and the yarn feeder base 200 and can drive the linkage base 300 to move up and reset, the auxiliary reset mechanism is arranged on the yarn feeder base 200 to move left and right and can assist in driving the linkage base 300 to move up and reset.

[0049] Combine image 3 , Figure 4 The weft inserted yarn feeder device is arranged on the top p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com