Accurate oiling device for producing hardware

A precise and hardware-based technology, applied in the processing of textile material equipment configuration, textile and papermaking, liquid/gas/steam textile material processing, etc., can solve the problems of high fuel consumption and complex structure, and achieve fast oiling speed and excellent structure Simple, waste-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

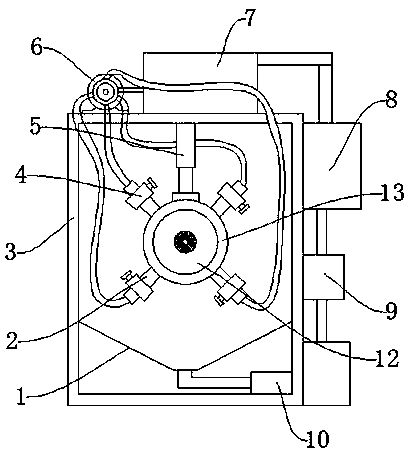

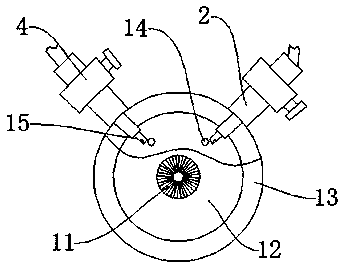

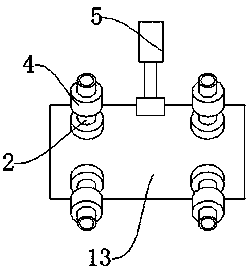

[0020] Below in conjunction with accompanying drawing, the application is further described:

[0021] Such as figure 1 As shown, a precision oiling device for hardware production includes a box body 3 and an oil storage tank 7. A deflector 1 is arranged at the inner bottom of the box body 3, and a filter 10 is arranged on the oil outlet pipe below the deflector 1. An oil return pump 9 is arranged on the outer wall of the body 3, a controller 8 is arranged above the oil return pump 9, an oil storage tank 7 is arranged on the top of the box body 3, an oil delivery pump 6 is arranged next to the oil storage tank 7, and a support rod 5 is arranged on the top of the box body 3 , an outer casing 13 is arranged below the support rod 5, a fuel injection pipe 2 is arranged on the outer wall of the outer casing 13, a solenoid valve 4 is arranged on the fuel injection pipe 2, a nozzle 15 is arranged at the end of the fuel injection pipe 2, and a nozzle 15 is arranged next to the nozzle 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com