Vibration-wave vane of cloth guide roller

A cloth guide roller and blade technology, used in the fields of textile, printing and dyeing machinery and equipment, can solve the problems of sharp corners at the connection between the top surface and the side surface, easy to damage the cloth surface, etc., to increase adhesion, avoid damage, and increase friction. Effect

Inactive Publication Date: 2018-05-18

TAIZHOU ZHONGXIANG MACHINERY MFG

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The cross-section of this blade is rectangular, and the main defect is that the connection between the top surface and the side surface is a sharp corner, which is easy to damage the cloth surface during use.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0012] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

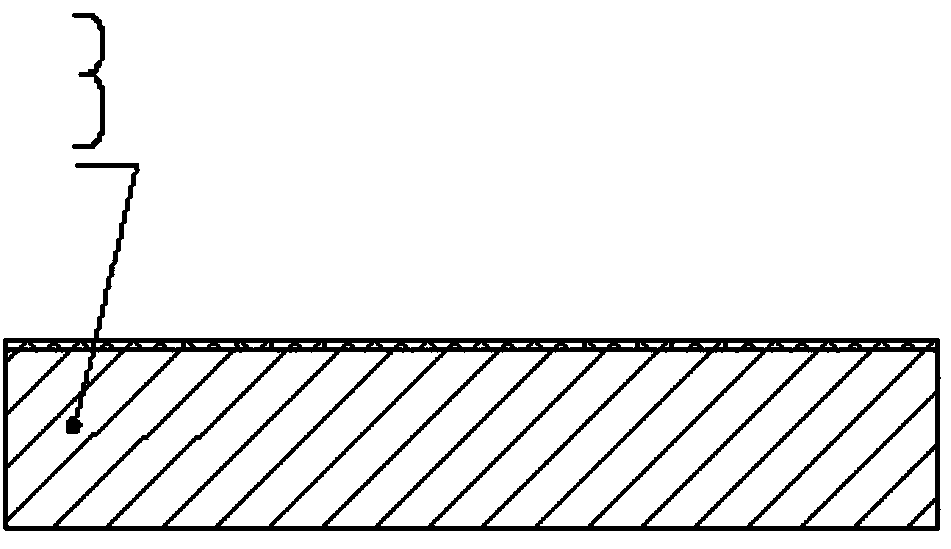

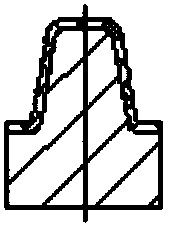

[0013] The blade of the vibrating waveguide cloth roller shown in the accompanying drawing is a straight strip 3, and the cross section of the straight strip 3 is provided with a trapezoidal top. .

[0014] The outer surface of the trapezoidal top of the straight bar 3 is provided with a rubber layer.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a vibration-wave vane of a cloth guide roller. The vibration-wave vane is a straight bar, wherein the cross section of the straight bar is provided with a trapezoidal top; thetop surface of the trapezoidal top of the straight bar is a plane; two side surfaces of the trapezoidal top of the straight bar are bevels; junction surfaces of the top surface and the side surfaces are cambered surfaces; a further improvement is that the external surface of the trapezoidal top of the straight bar is provided with a rubber layer. The vibration-wave vane can be used for preventinga cloth cover from being damaged and is used for increasing the adhesive force, on the vane, of piece goods.

Description

technical field [0001] The invention relates to the field of textile, printing and dyeing mechanical equipment, in particular to a cloth guide roller blade used for fabric transmission in open width. Background technique [0002] In the textile, printing and dyeing industry, the cloth guide roller mainly plays the role of supporting and stably conveying the textile. There is a blade-type cloth guide roller on the market. There are many axial blades installed on the outer surface of the cloth guide roller body. The blades on the periphery of the roller body guide the cloth and stir the dye in the dyeing tank. The blades stir the dye liquid to impact the wiring and remove the impurities in the wiring. The cross-section of this blade is rectangular, and the main defect is that the connection between the top surface and the side surface is a sharp angle, and it is easy to damage the cloth surface during use. Contents of the invention [0003] Aiming at the deficiencies of th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D06B23/02

CPCD06B23/026D06B23/023

Inventor 李秋忠

Owner TAIZHOU ZHONGXIANG MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com