Special clamping assembly-connection flange structure

A connection flange, a special technology, applied in the field of snap-fit assembly connection flange structure, can solve the problems of reduced assembly operation efficiency, increased workload, increased use cost, etc., to achieve high assembly efficiency, convenient assembly, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

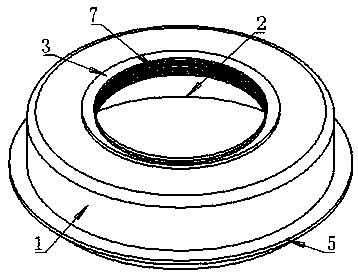

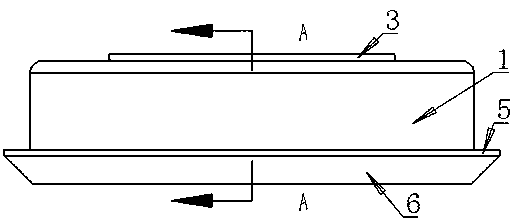

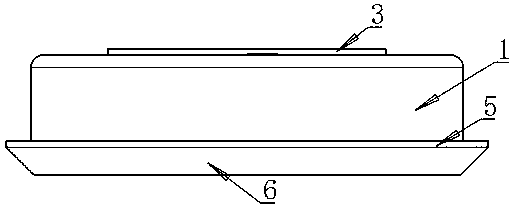

[0018] Such as Figure 1 to Figure 8 As shown, a special snap-fit assembly connection flange structure, which is more convenient to assemble during use, can make mechanical equipment and flange parts firmly assembled without using other structures, and can also play a role after assembly. It has a certain anti-falling effect. It has stronger tightness and higher sealing performance during connection and assembly. Lubricating fluid can be set in its internal chamber so that it can lubricate the assembly structure when necessary, so that the flange parts The use range is wider, and the overall assembly efficiency is higher, and the assembly stability is also better and more reliable. It includes a cylindrical main body connecting column 1, and the lower end of the main body connecting column 1 is provided with a concentrically distributed cylindrical central assembly hole 2, and its position can be used as a lubricating fluid chamber when necessary. The distance from the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com