A high-performance carbon fiber composite piston rod and its preparation method

A piston rod and carbon fiber technology, applied in the direction of piston rods, mechanical equipment, engine components, etc., can solve the problems of easy failure of piston rods and affect the appearance quality, achieve excellent performance and appearance quality, improve use efficiency, and increase service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention are described in detail below: the present embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation and specific operation process are provided, but the protection scope of the present invention is not limited to the following implementation example.

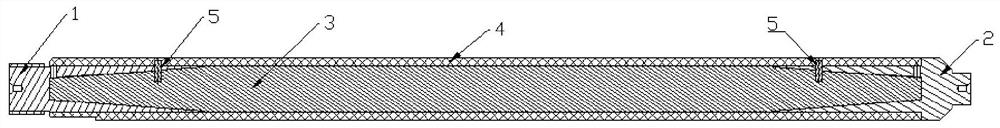

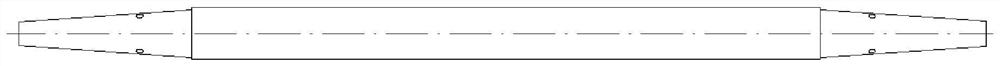

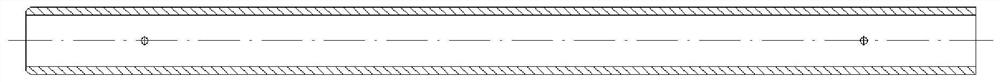

[0035] like Figure 1-Figure 5 As shown, the embodiment of the present invention provides a high-performance carbon fiber composite piston rod, which includes a piston joint 1, a piston rod main body, and a thrust rod joint 2 connected by pins 5 from left to right. The main body is composed of an inner piston body 3 and an outer piston body 4 sleeved outside the inner piston body 3. Contact connections are provided between the inner and outer surfaces of the piston joint 1 and the thrust rod joint 2, and the piston joint 1 and the thrust The inner surfaces of the rod joints 2 are all tapered, with a cone angle of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com