Detector of rebound apparatus

A technology of a rebound hammer and a fixed guide rail is applied in the field of the testing device of the hammer, which can solve the problems of inconvenient use, distorted testing data of the calibrator, and inability to test multiple indicators at the same time, so as to achieve convenient operation, improve detection accuracy, The effect of easy firing and position control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

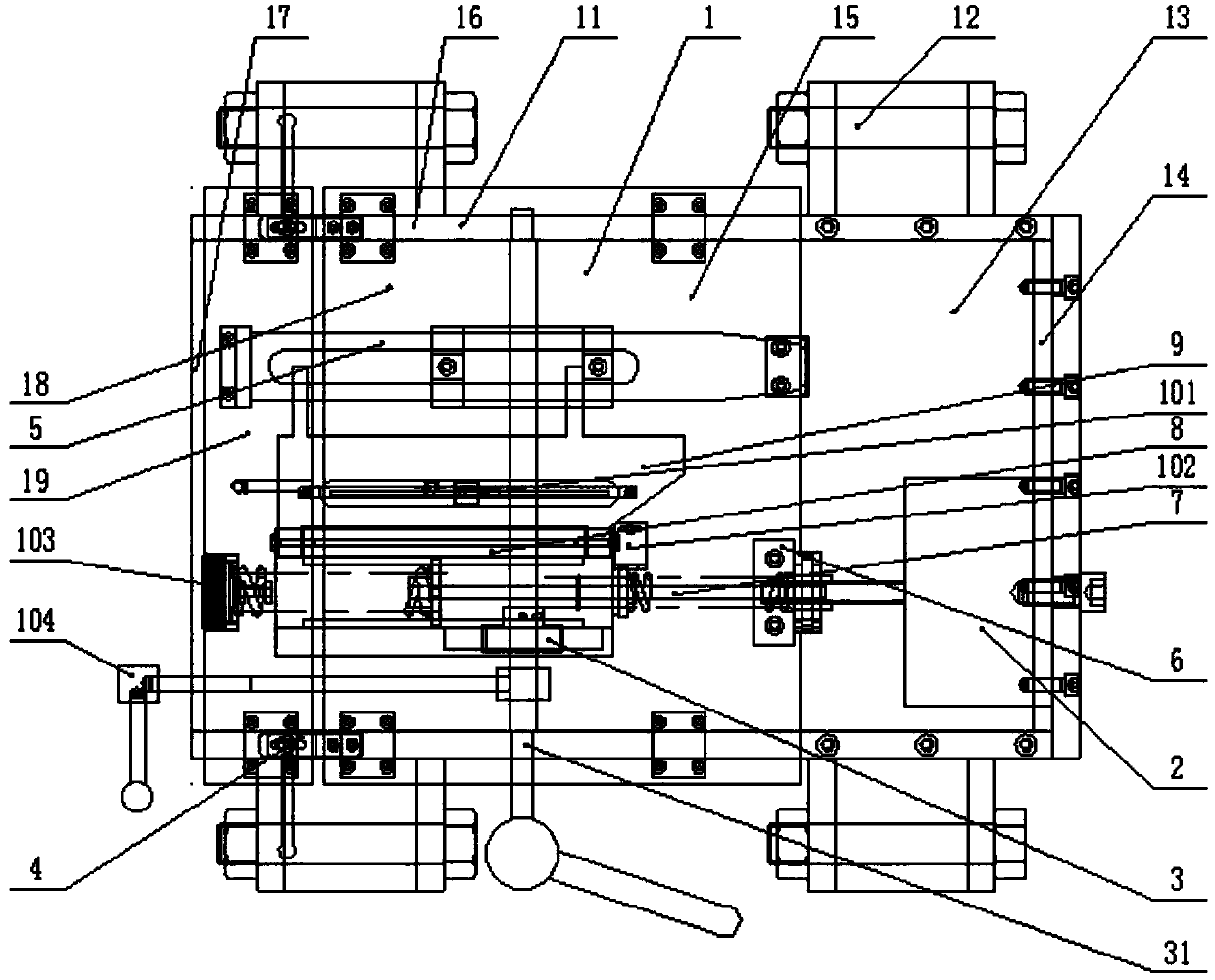

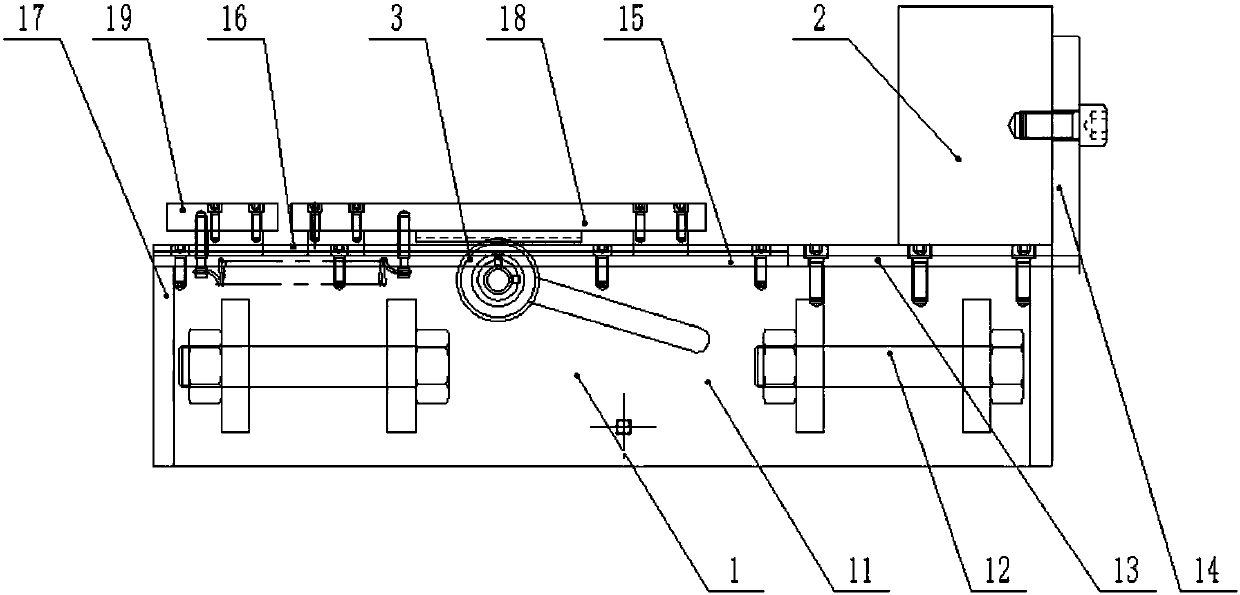

[0064] A tester for a rebound instrument, comprising: a base part 1 including side plates 11 on both sides and a rear cover 17, the upper right side of the base part 1 is fixed with a steel anvil base 13, and the steel anvil 2 passes through the back stop of the steel anvil Plate 14 is installed on described steel anvil base 13 (referring to Figure 1-2 );

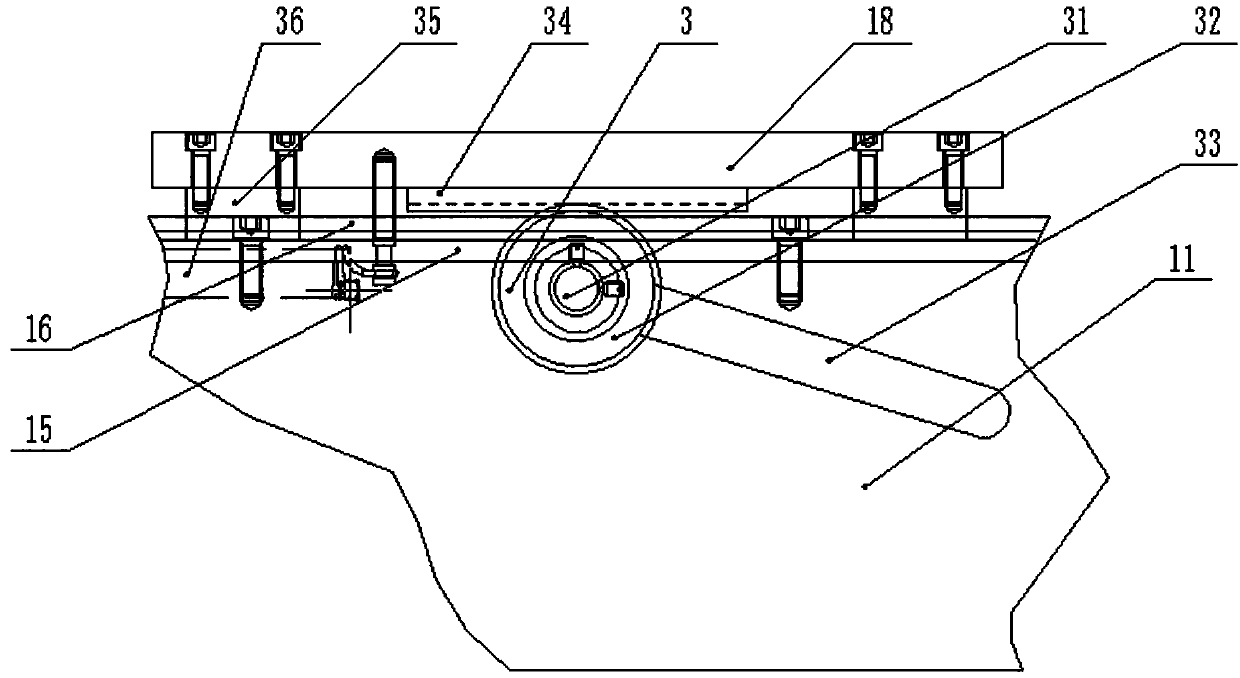

[0065] The top of the side plate 11 is installed with a slideway 16 through bolts, and the two sides of the bottom plate 15 are installed with a slide block 35 through bolts. Realize the translation motion pair; (see figure 2 ), two handles 12 are installed on the side panels 11 on both sides.

[0066] The main sliding plate 18 and the auxiliary sliding plate 19 are slidably connected with the slideway 16 through the slider 35, the main sliding plate 18 is located on the right side of the auxiliary sliding plate 19, and the main sliding plate 18 and the auxiliary sliding plate 19 pass through the fixed guide rail parts ...

Embodiment 2

[0074] Embodiment 2: The structure is the same as that of Embodiment 1, and the support sleeve 105 is added to be installed between the rear pull baffle 103 and the movement part 7 . The support cover 105 includes a support cover base 1051 embedded in the rear pull baffle 103, a support cover positioning part 1053 fixed to the guide bar 82 and an internal support cover through hole 1052 (see Figure 23-24 ), the effect of increasing the support sleeve 105 is: when the length of the return spring is longer, the support sleeve 105 is fixed between the rear pull baffle plate 103 and the guide bar 82, and the return spring moves in the support sleeve through hole 1052 to prevent the return spring from Jump out during compression.

[0075] The calibrator completes multiple detection indexes of the rebound hammer in one device, which is convenient for operators to operate and improves work efficiency at the same time. The main slide plate and the auxiliary slide plate are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com