Cable terminal head fabrication method capable of improving local insulation performance

A technology of insulation performance and manufacturing method, applied in the direction of equipment for connecting/terminating cables, etc., to achieve the effect of improving the distribution of electric field intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

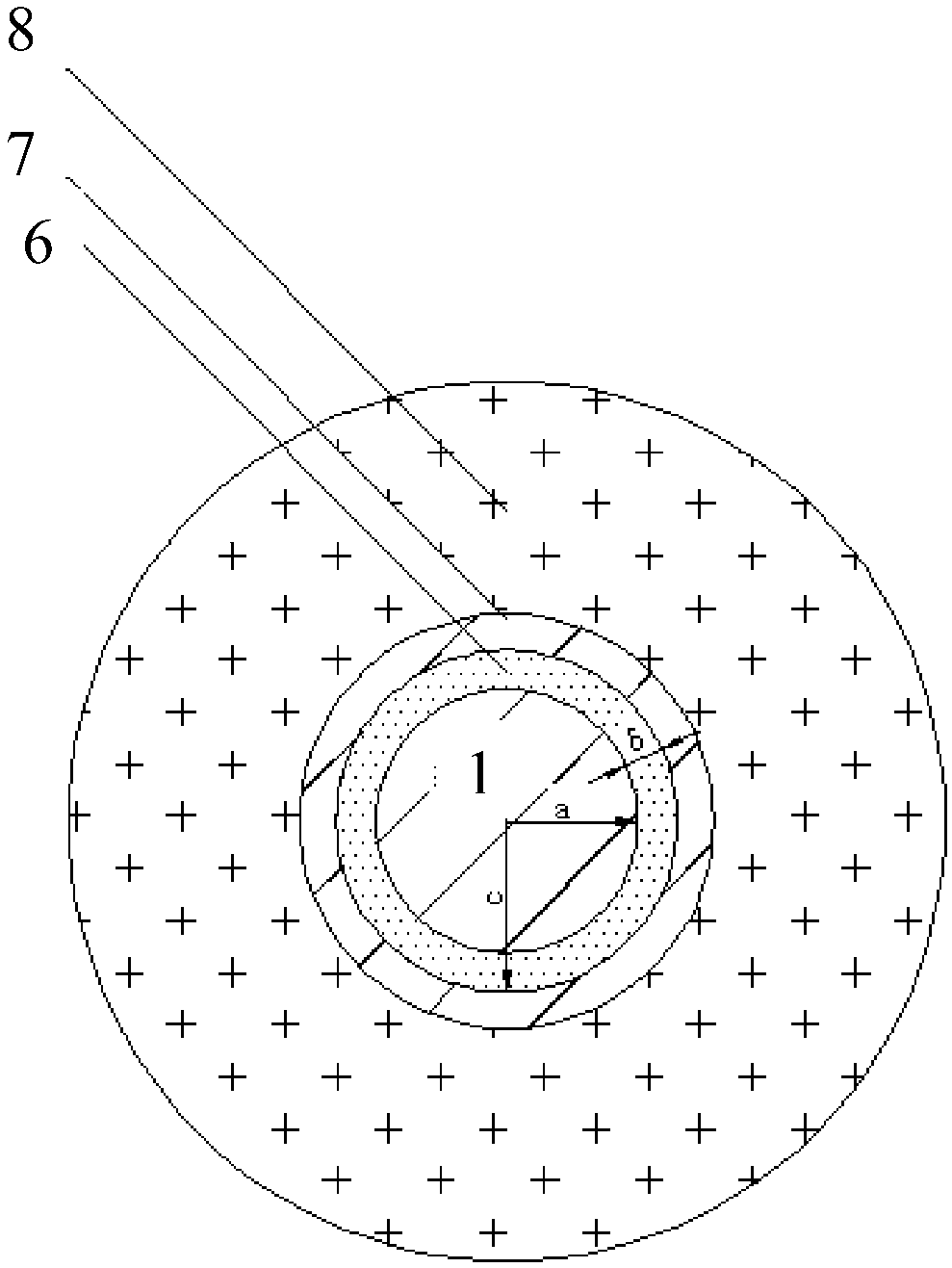

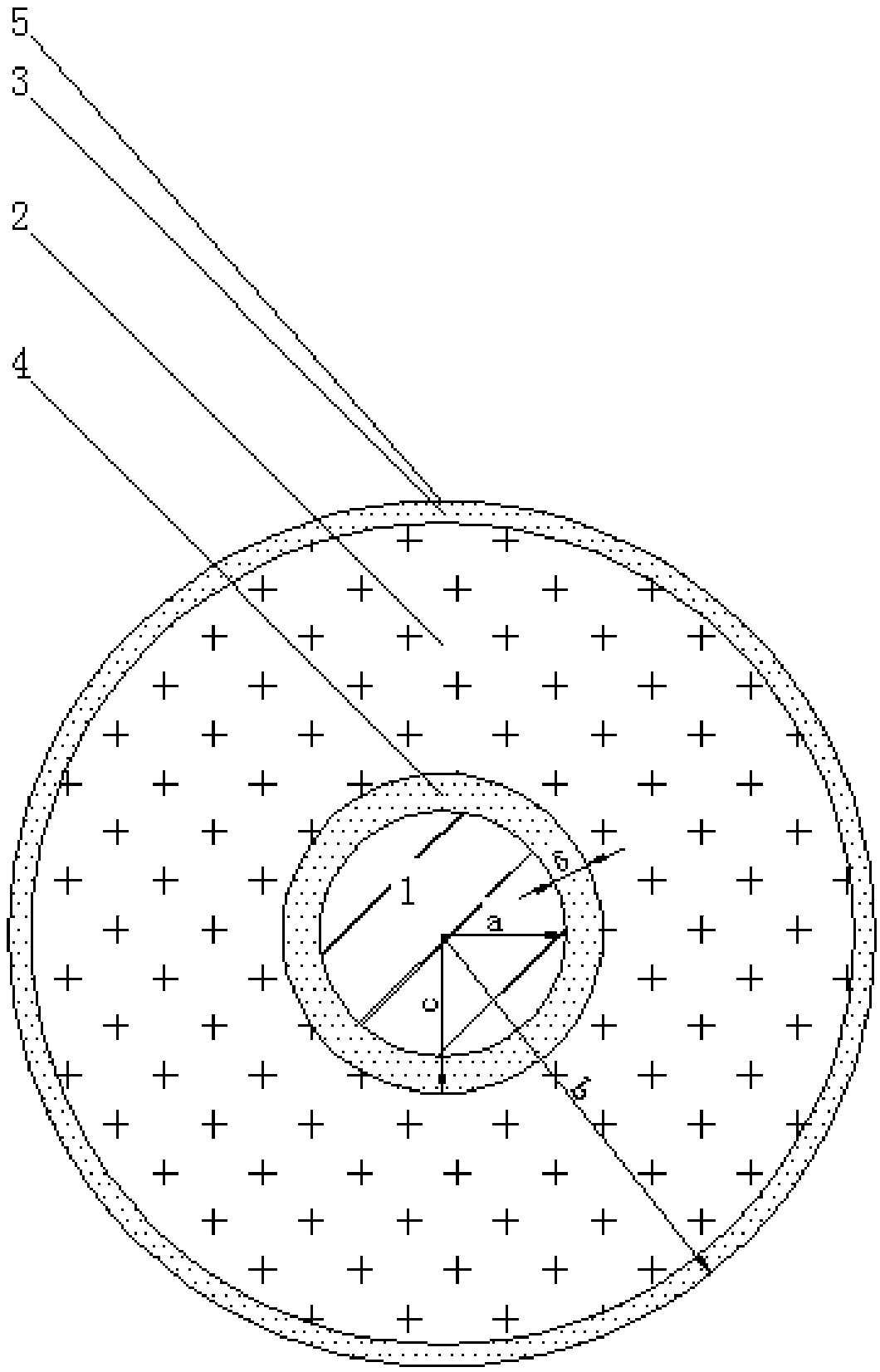

[0087] Taking copper core XLPE insulated PVC sheathed power cable YJQ02-Z-220kV-1×240 as an example, its main parameters are:

[0088] a=15.5mm;

[0089] l=1000m;

[0090] L=0.1m;

[0091] The value of the thickness δ of the semiconducting strip 6 should be the same as figure 2 The thickness of the inner shielding layer 4 of the medium cylindrical high-voltage cable is the same, that is, 1.5mm, so c=15.5+1.5=17mm;

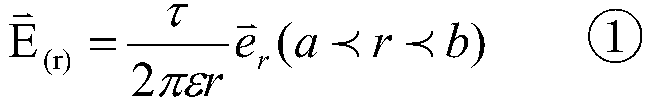

[0092] From formula (16) can get x=1.0968*10 4 , that is, the extreme value of the electric field intensity on the inner surface of the cold-shrinkable insulator 8 is only the electric field intensity on the surface of the conductor

[0093] When the impurity concentration of 100 μm in the insulating layer 2 increases by 5 times, its power frequency and impact breakdown strength (breakdown probability is 63%) decrease by 17% and 14% respectively, namely:

[0094] The power frequency breakdown strength of the inner surface of the cold-shrinkable insulating pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com