Damping radiating motor

A technology of motor shells and shock absorbing sleeves, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of rebounding vibration force, difficulty in removing hot air, general heat dissipation effect of motors, etc., and achieves extended service life and heat dissipation effect Obvious, weakening effect of vibration energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

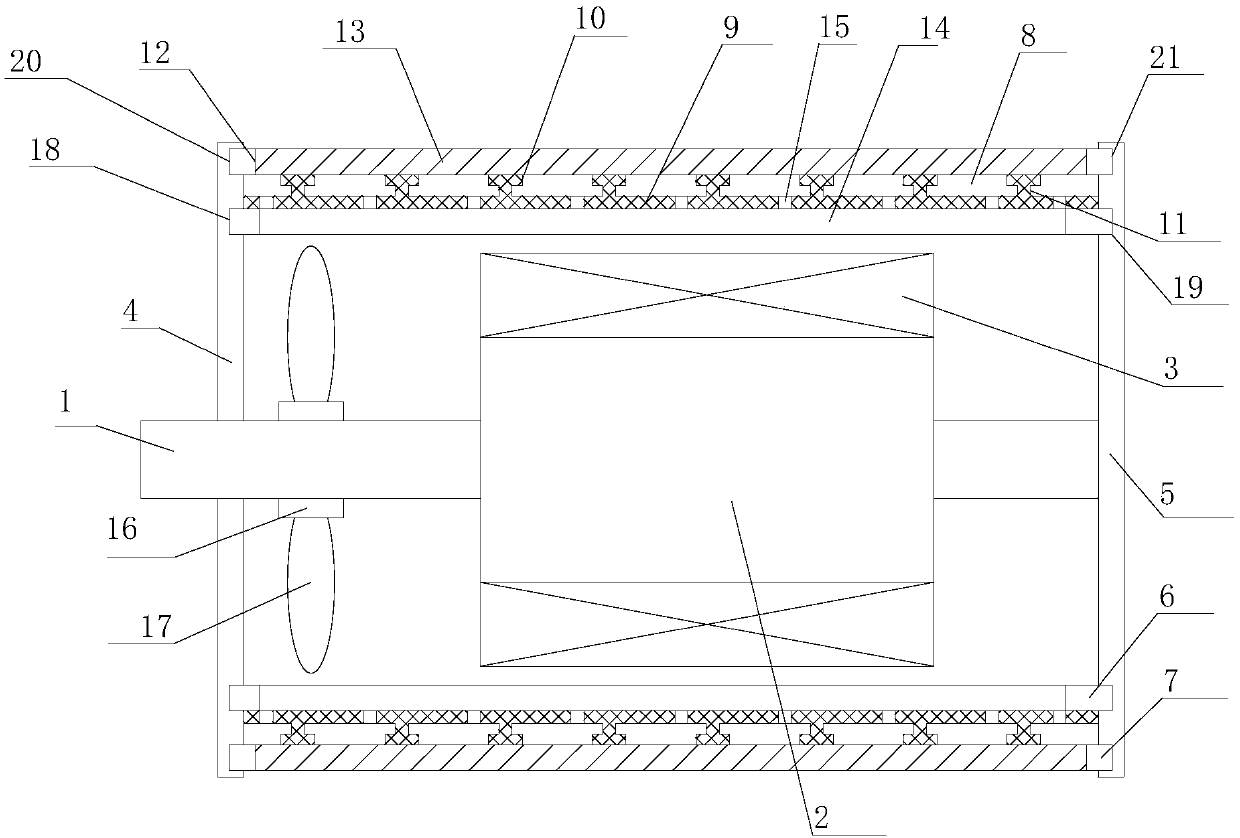

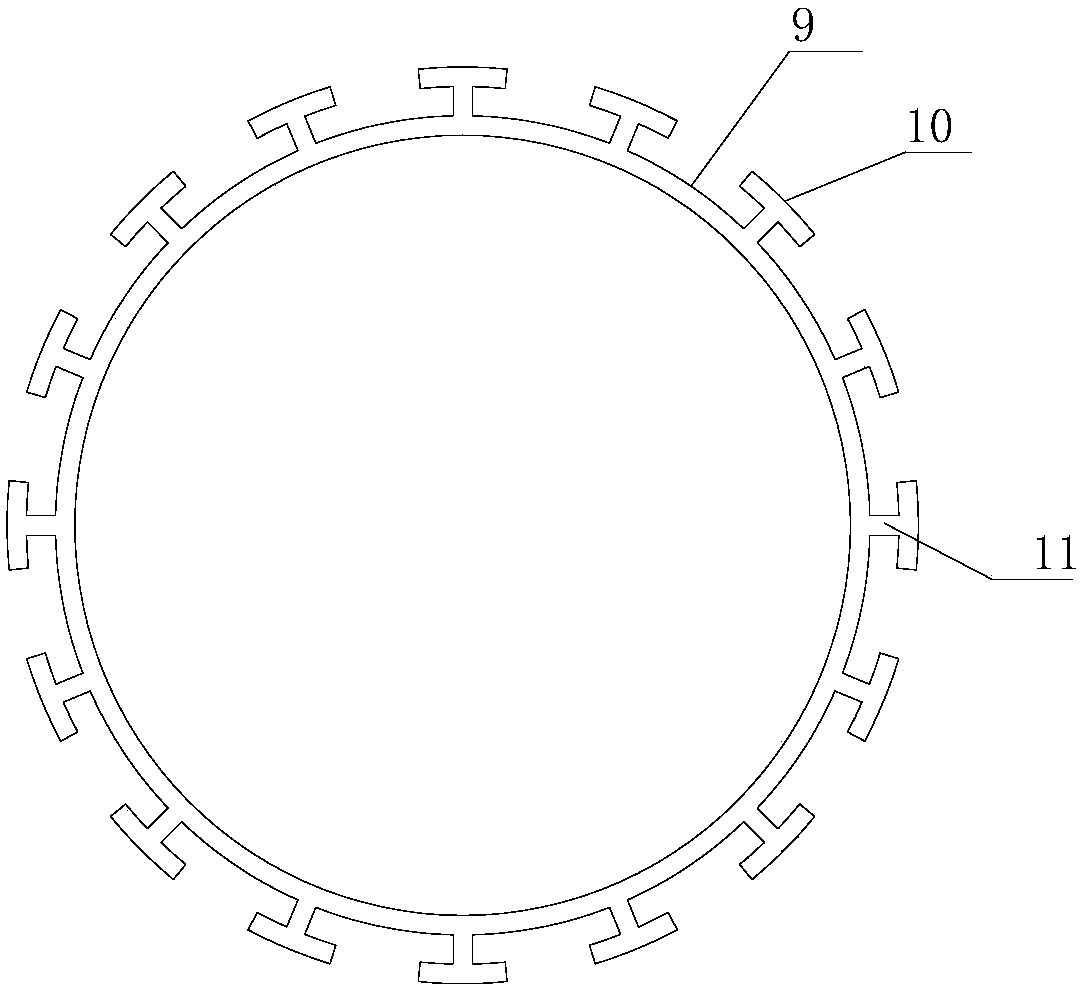

[0014] Such as figure 1 , figure 2 as shown, figure 1 It is a structural schematic diagram of a shock-absorbing and heat-dissipating motor proposed by the present invention; figure 2 It is a structural schematic diagram of a shock absorber in a shock absorber and heat dissipation motor proposed by the present invention.

[0015] refer to figure 1 , figure 2 , the present invention proposes a shock-absorbing and heat-dissipating motor, including a rotor shaft 1, a rotor 2 mounted on the rotor shaft 1, a stator 3 arranged on the outer periphery of the rotor 2, and a stator 3 and the rotor 2 arranged on the outer periphery of the stator 3. Protective motor housing, in which:

[0016] The first end cover 4 and the second end cover 5 are sealed and connected at both ends of the motor casing. The first end cover 4 is provided with a concentric arrangement of the first annular slot 18 and the third annular slot 20, and the third annular slot The diameter of the groove 20 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com