Novel position adjusting structure material stopping block

A technology for adjusting the structure and the material stopper, which is applied to brushes, household appliances, applications, etc., can solve the problems of the material stopper mechanism being held by the brush handle, the material stopper mechanism cannot be adjusted, and the production process of the brush handle is affected. Guarantee the effect of use and optimize work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

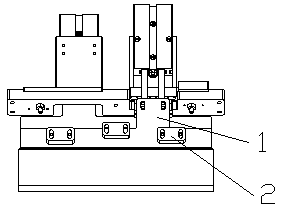

[0012] A new type of position adjustment structure block, including a limit plate 1 and a limit block 2, the limit plate 1 and the limit block 2 are connected to each other, the limit block 2 is located on the top of the limit plate 1, and the limit block 2 limits The height of the position is adjustable, and there is an accommodation space at the end of the limit plate 1. The size of the accommodation space changes with the adjustment of the limit plate 1 and the limit block 2. The limit block 2 realizes the adjustment of the limit plate 1 through the adjustment of the upper and lower heights. Limit, the limit plate 1 is an adjustable limit plate, the limit plate 1 is adjustable in both directions, and the brush handle is accommodated in the accommodation space, the accommodation space formed by the limit plate 1 is adjusted with the diameter of the brush handle, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com