Multi-container chemical reactor

A chemical reactor and multi-vessel technology, applied in the field of reactors, can solve the problems of inability to conduct multiple chemical experiments at the same time, uneven heating of heating vessels, and single structure, saving experiment time, ensuring reliability, The effect of improving experimental efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

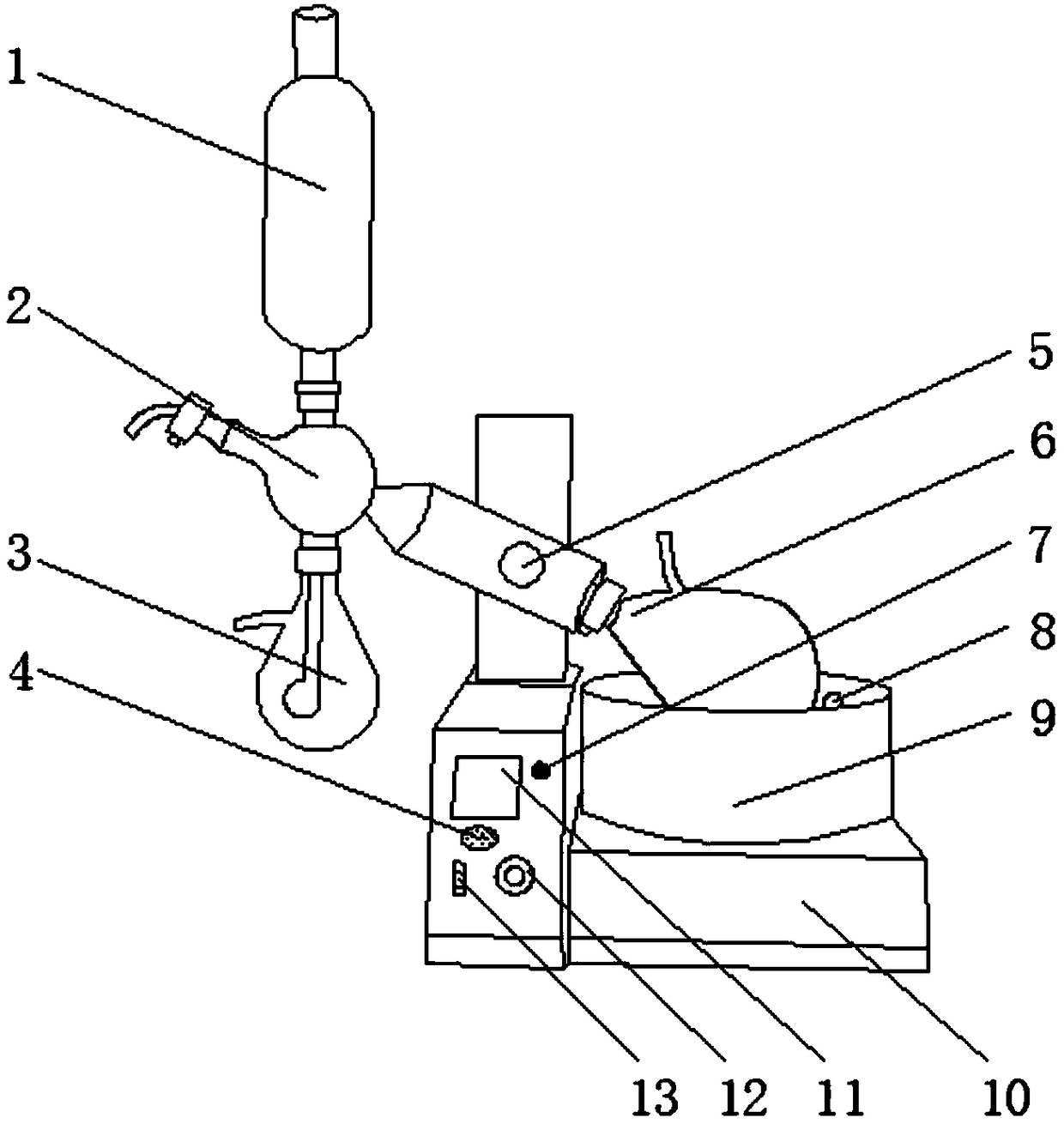

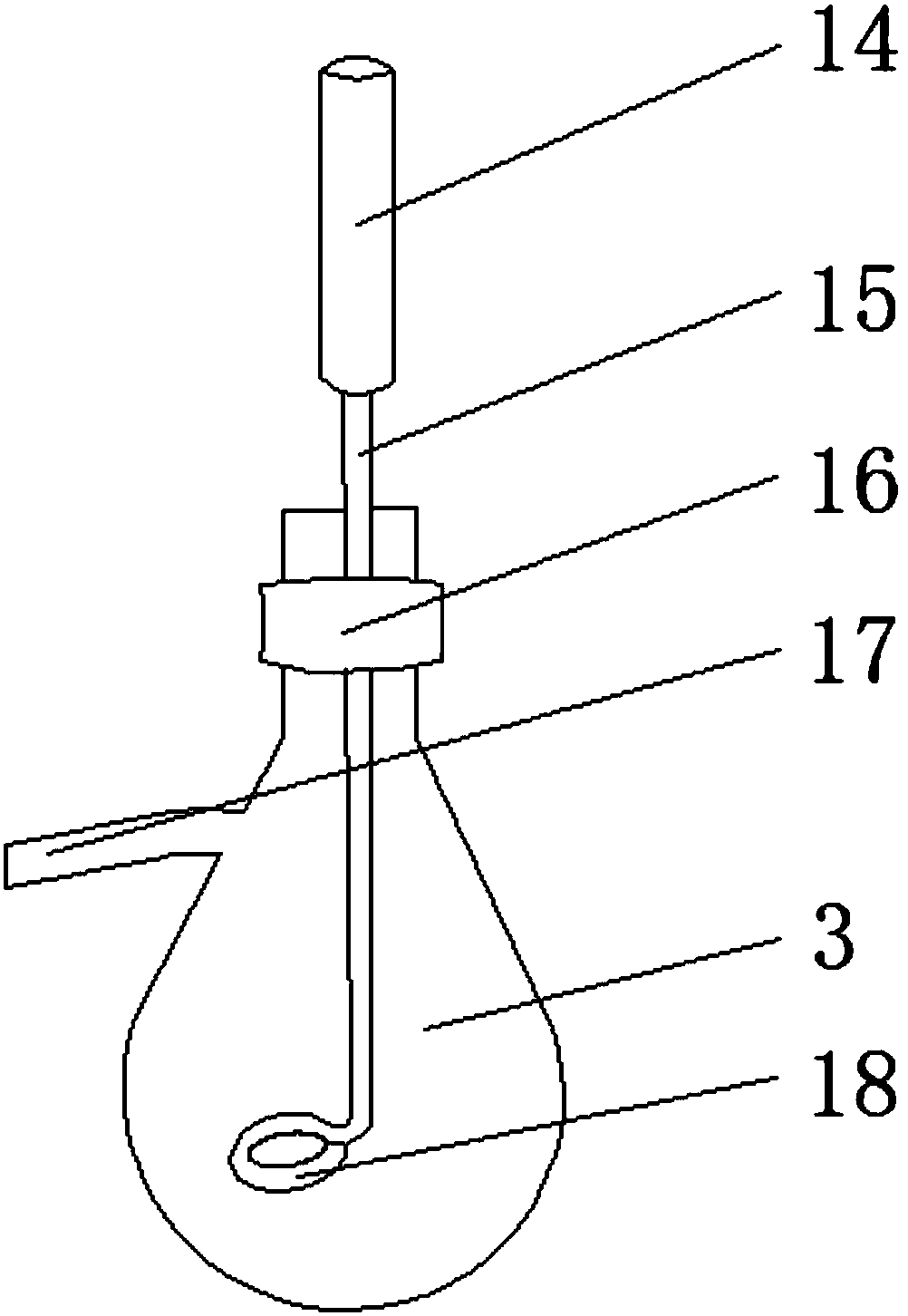

[0015] refer to Figure 1-2 , during a multi-vessel chemical reactor, comprising a second reaction vessel 2, a main reactor 3, a lifter 5, a heating bath 9, a base 10, a display screen 11 and a bottle stopper 16, the left side of the base 10 is equipped with a first Reaction vessel 1, and the second reaction vessel 2 is installed below the first reaction vessel 1, the main reactor 3 is installed on the right side below the second reaction vessel 2, and the lifter 5 is installed on the right side of the main reactor 3, the lifter 5, a power indicator light 7 is installed on the right side below the power indicator light 7, and a heating bath 9 is installed under the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com