Walking wheel composite structure and driving walking wheel and driven walking wheel using same

A composite structure and traveling wheel technology, applied in the directions of traveling mechanism, load hanging components, transportation and packaging, etc., can solve the problems of heavy cast steel traveling wheels, unfavorable production operations, and difficulty in moving, etc. The effect of rail gnawing and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

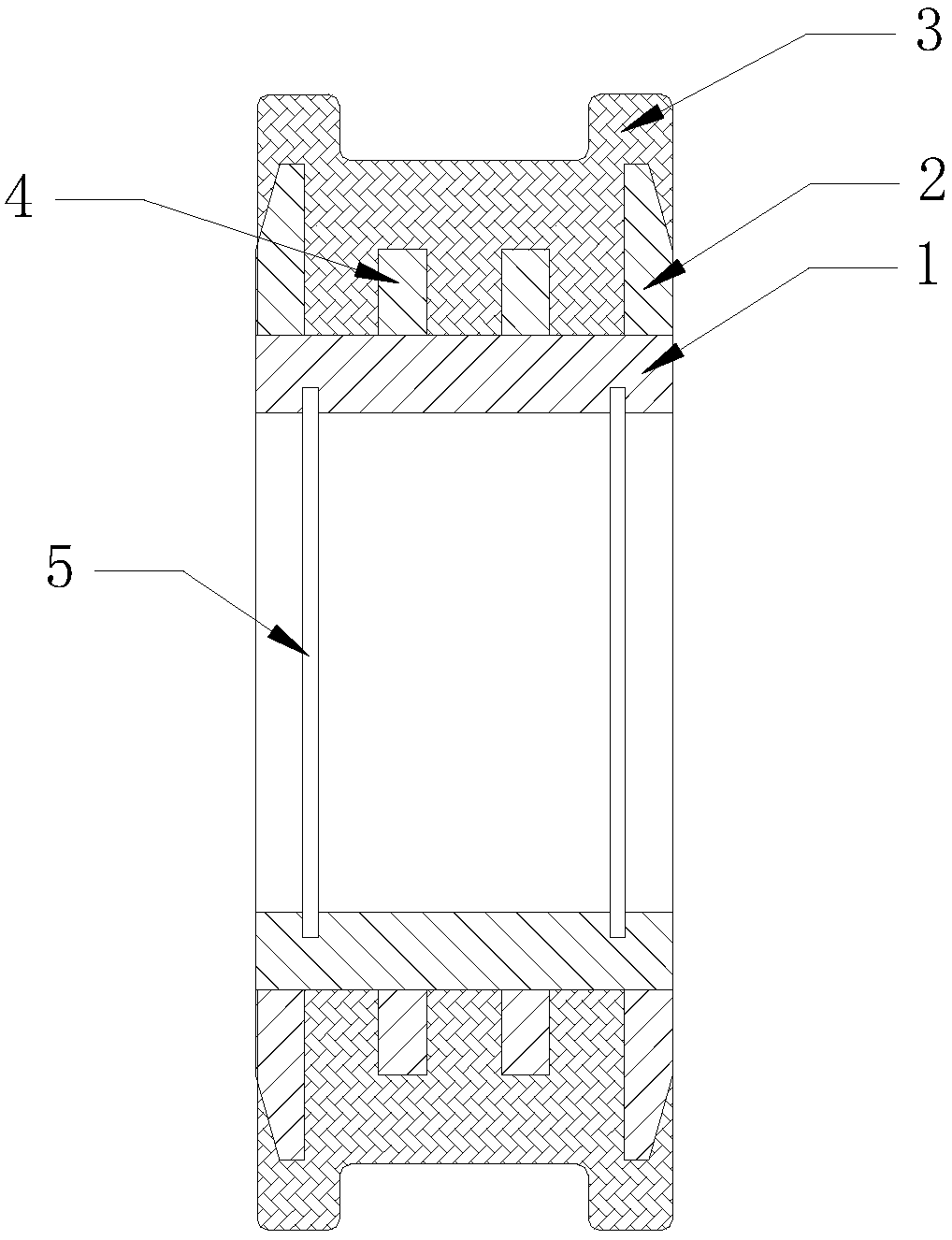

[0029] Embodiment 1: A passive walking wheel, including four structures, a cylindrical wheel core 1, a defective annular fillet welded on the side surface of the wheel core 1, vacuum injection molded on the wheel core 1 and the insert The engineering plastic 3 on the outer layer of the side of the bar, and the groove 5 used for installation on the inner side of the wheel core 1.

[0030] Such as figure 1 , the groove 5 is annular, set inside the wheel core 1, the annular surface is parallel to the bottom surface of the road wheel, and the distances between the two grooves 5 and the two bottom surfaces are equal. In fact, this structure is only to adapt to the application Mechanically mounted, so the structure is not fixed. There are four moldings, two inner moldings, two side moldings 2, the side moldings 2 are set at both ends of the side of the wheel core 1, and the inner layer of the wheel rim; the inner molding A4 is set between the side moldings 2 Between, the inner mol...

Embodiment 2

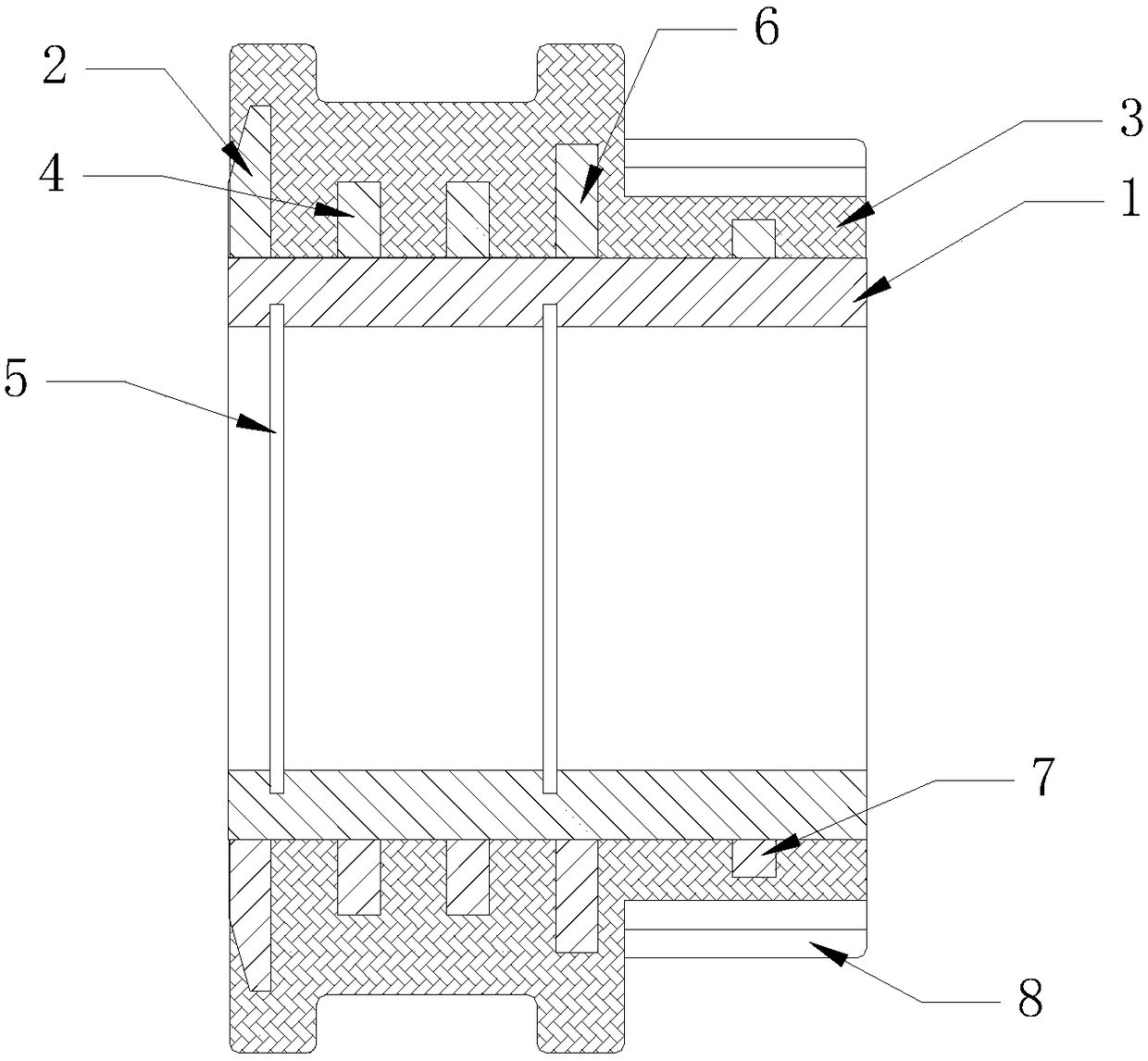

[0034] Embodiment 2: A kind of driving wheel, also includes four kinds of structures, cylindrical wheel core 1, defective ring-shaped fillet welded on the side surface of wheel core 1, injection molded on wheel core 1 and insert The engineering plastic 3 on the outer layer of the side of the bar, and the groove 5 used for installation on the inner side of the wheel core 1. The feature is that the integrally formed shape during vacuum injection molding on the engineering plastic 3 has a rack 8 in addition to the wheel rim, and the rack 8 is the main feature that distinguishes the active wheel from the passive wheel.

[0035] In order to adapt to this feature and ensure the stability of the composite structure of the road wheel, it is necessary to make certain adjustments to the position of the fillet and re-explain the position of the wheel rim. Such as figure 2 , the engineering plastics 3 includes two shapes of two rims and rack 8, wherein one rim and rack 8 are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com