Braking structure of sweater sewing device

A technology for sewing devices and sweaters, which is applied to sewing machine control devices, sewing equipment, sewing machine components, etc., can solve the problems of complex structure and inconvenient operation, and achieve the effects of long service life, simple structure, and easy stepping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

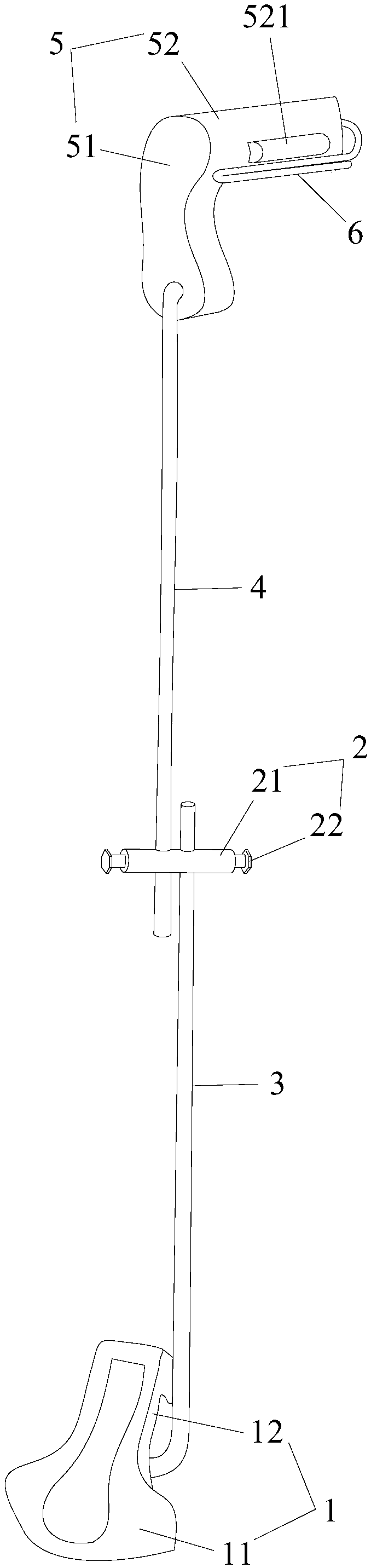

[0015] Please refer to figure 1 , the brake structure of the sweater sewing device includes a foot pedal 1, a height adjusting member 2, a vertical connecting rod 3, a vertical connecting rod 2 4, a swing rod 5 and a pull rod 6, the height adjusting member 2, the vertical Connecting rod one 3, vertical connecting rod two 4, fork 5 and pull rod 6 all adopt metal materials, thereby long service life.

[0016] The pedal 1 is an elastic soft rubber structure, and its inside is solid, so it is comfortable to use. The pedal 1 has a fixed part 11 fixed on the ground and a suspended part 12 extending from the fixed part 11. The upper surface of the pedal 1 is a slope structure, which is convenient for pedaling. There are friction bumps on the surface of the pedal 1 . The height adjusting member 2 includes a sleeve 21, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com