Method for Analysis of Glass Defects Using Reflection Electron Probe

A technology of glass defects and reflected electrons, applied in material analysis using wave/particle radiation, material analysis using radiation diffraction, analyzing materials, etc. Simple and quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

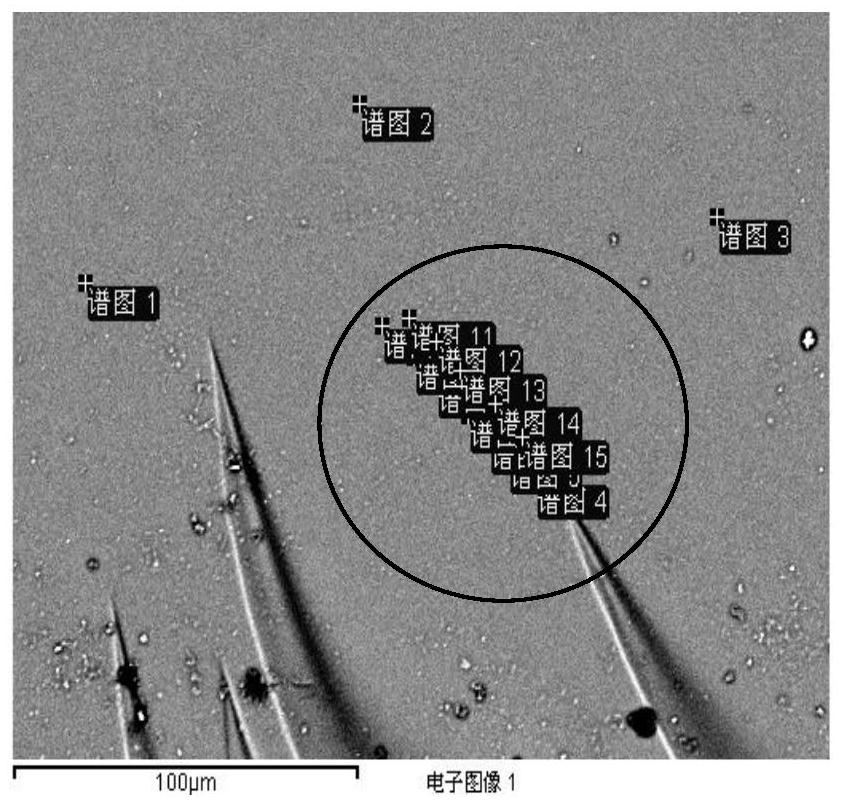

[0039] This example is used to illustrate the analysis of glass defects using the reflection electron probe using the method of the present disclosure.

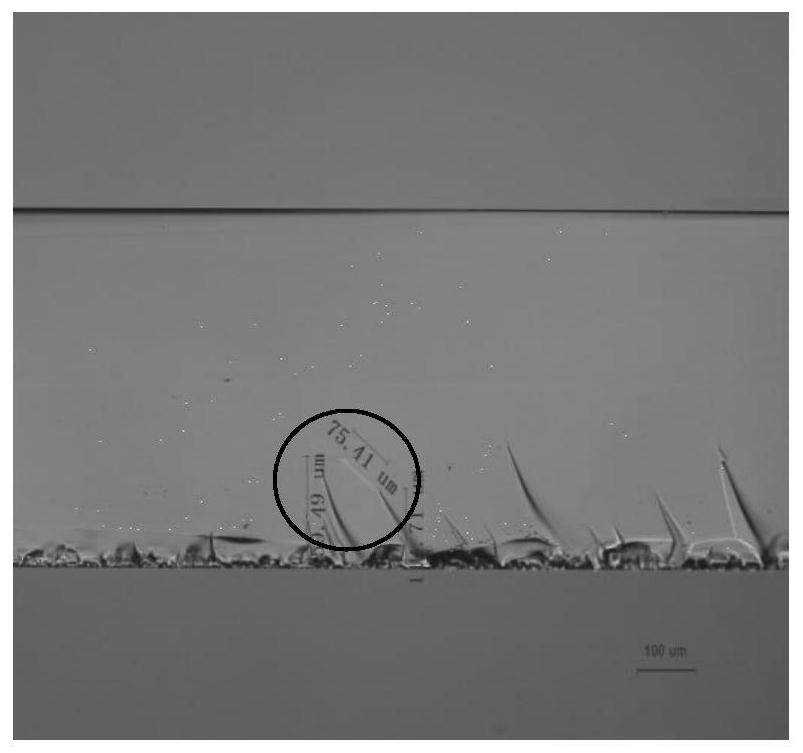

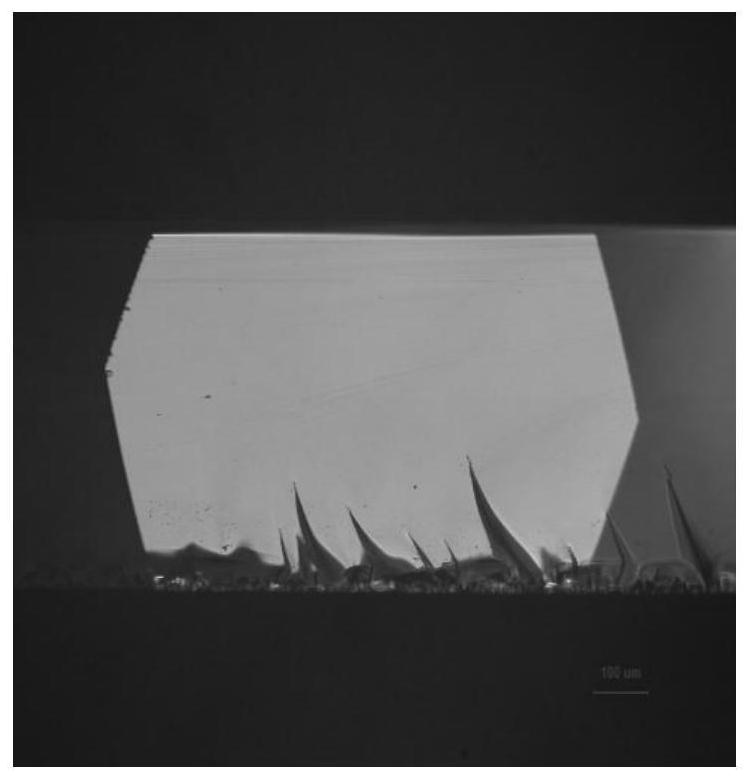

[0040] The glass sample adopted in this embodiment is electronic glass with a thickness of 0.5mm produced by C company, and its photo under a transmission microscope is as follows: figure 1 as shown, figure 1 In the circle, the position of the glass defect is located; the photo under the reflection microscope is as follows figure 2 shown, visible figure 2 No glass defects were observed in the glass.

[0041] Place the above glass sample under an optical transmission microscope, measure the depth of the glass defect from the upper surface of the glass to 111.71 μm, and the depth from the lower surface to 340.81 μm, mark the position of the glass defect on the upper surface of the glass, and obtain the distance from the glass defect as 0.5 ~ 2mm defect mark.

[0042] Place the glass sample on a drawing with cutting markin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com