Fiber clamping joint on fiber quick-connection joint

A technology of optical fiber clips and connectors, which is applied in the field of communication accessories, can solve the problems of dropping and losing the fixing sleeve, troublesome, unusable optical fiber quick connectors, etc., and achieve the effect of convenient installation, clamping and fixing, and avoiding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

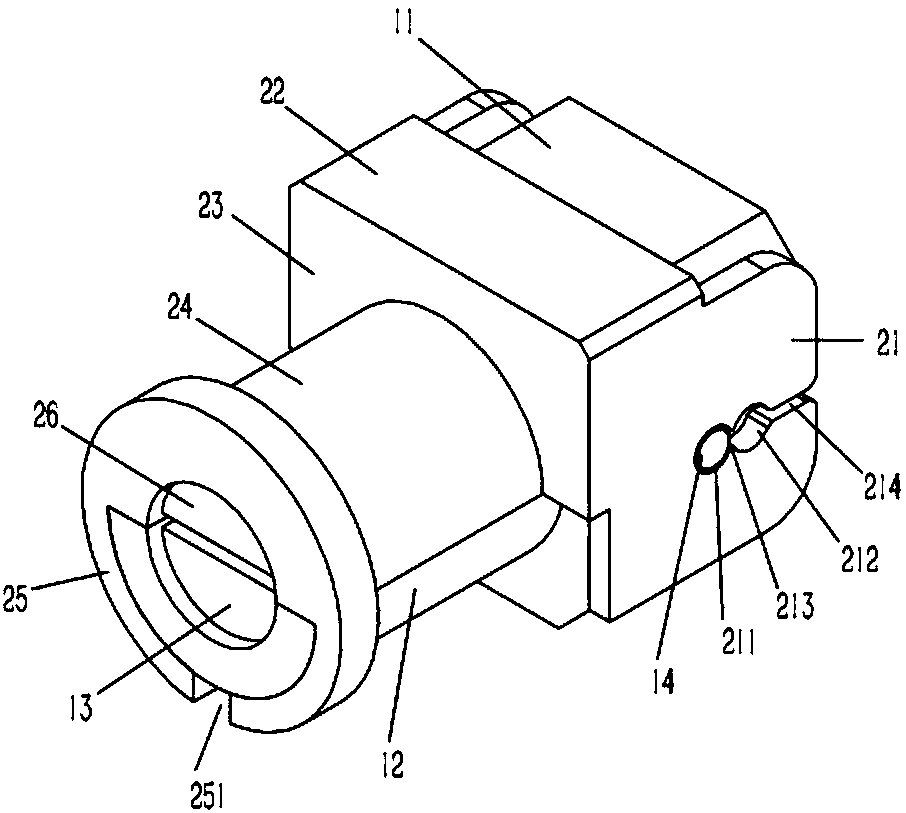

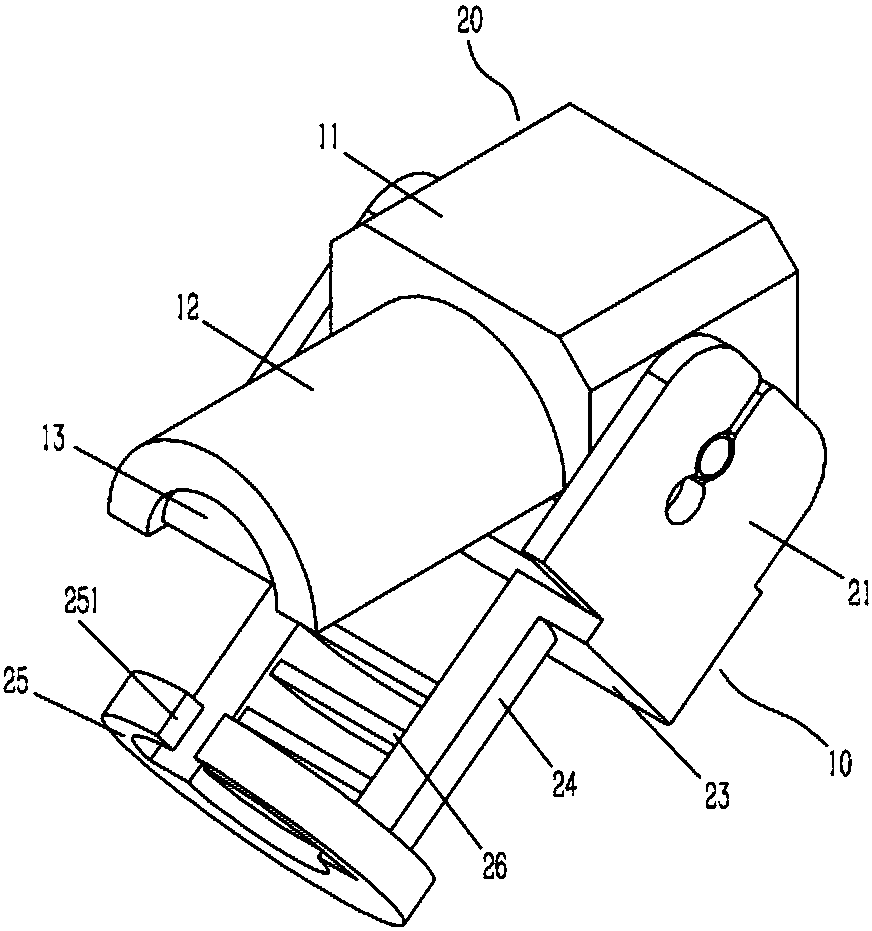

[0016] Example: see figure 1 , 2 As shown, an optical fiber clamping joint on a quick-connect optical fiber joint includes a joint seat 10 and a clamping seat 20. The joint seat 10 includes a rectangular seat body 11, and hinge columns 14 are formed on the two side walls of the seat body 11. A semicircular lower plate body 12 is formed on the front end surface of the seat body 11, and several D-shaped lower clips 13 are formed on the inner wall of the lower plate body 12. Side plate 21, side plate 21 is formed with connected front positioning hole 211 and rear positioning hole 212, hinge column 14 is inserted in the front positioning hole 211 of side plate 21; There is a circular arc transition 213, and the rear end of the rear positioning hole 212 is formed through the wire groove 214 on the rear end surface of the side plate 21; The upper plate body 24, the upper plate body 24 leans against the lower plate body 12 and is a circular post sleeve relative to the lower plate b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com