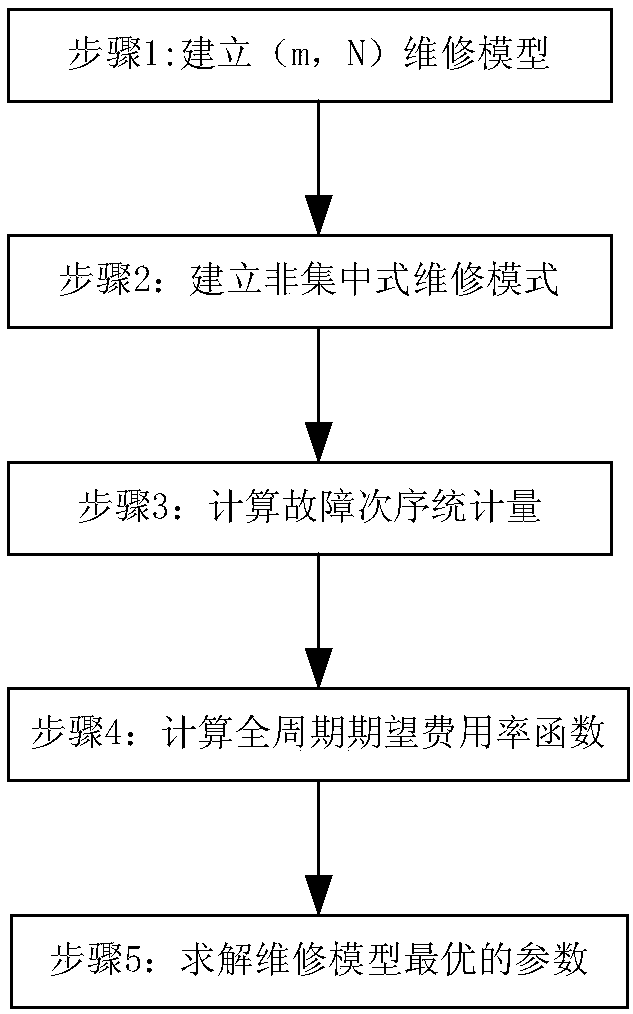

Task-and-efficiency matching-based electromechanical system interactive multi-model maintenance prediction method

An interactive multi-model, electromechanical system technology, applied in the field of interactive multi-model maintenance prediction of electromechanical systems based on task and performance matching, to achieve the effect of solving high maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

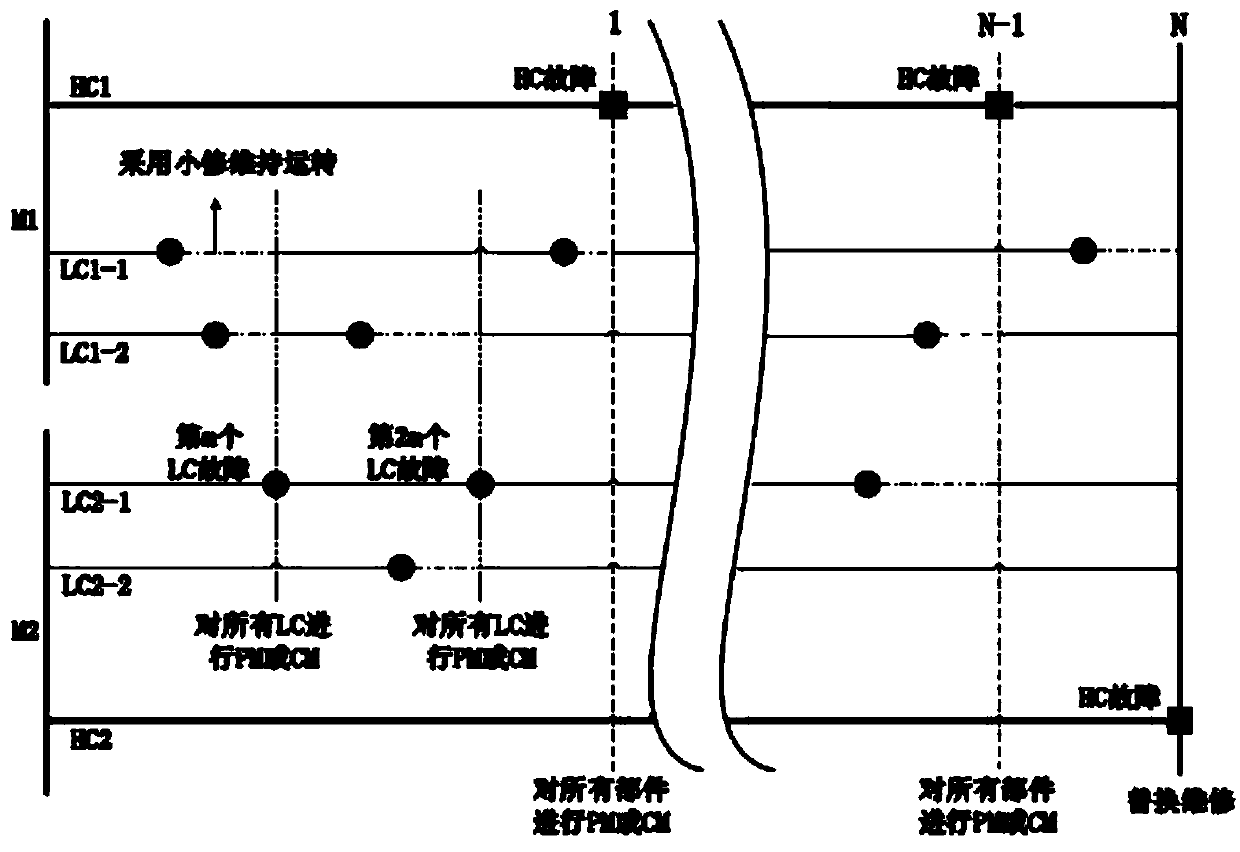

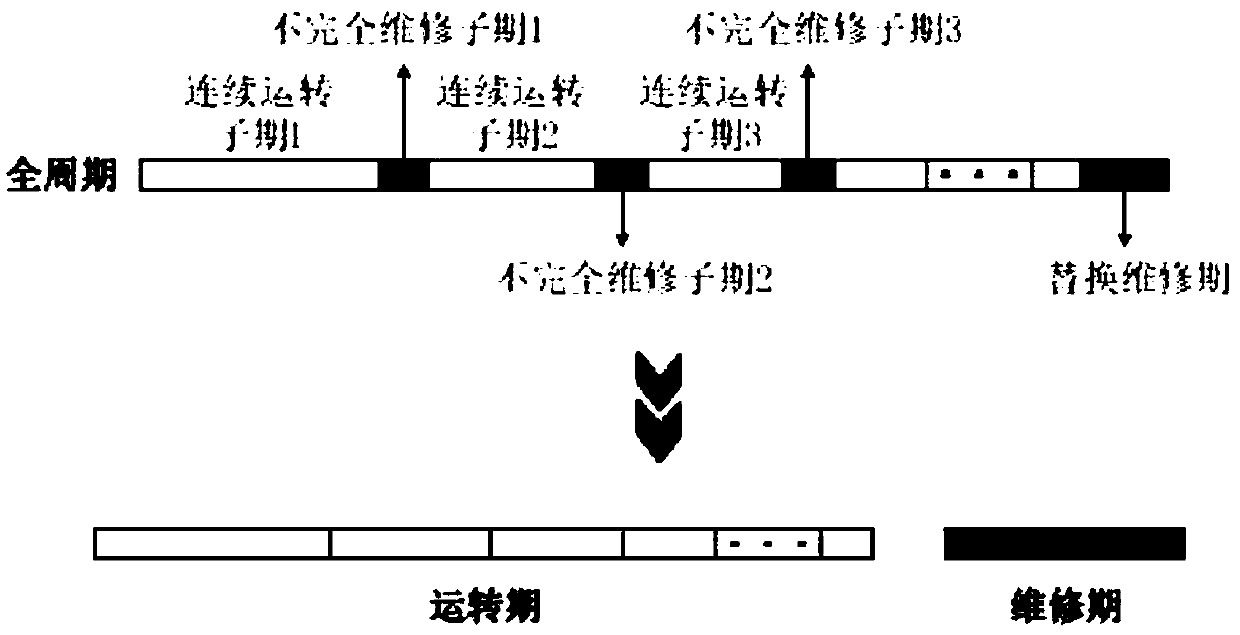

Method used

Image

Examples

example

[0100] The life of the component obeys the exponential distribution, that is, the life distribution function and The standard parameter settings are as follows: , the rate parameter λ of the exponential distribution 1 = 0.1, λ 2 = 0.3, the "first-after" state transition matrix between teams

[0101] Various maintenance cost parameters c M =500,c d =120,c s =50,c l =10,c An_L =12, c Af_L =15,c An_H = 24,c Af_H =30,c Bn_L =22,c Bf_L =25,c Bn_H = 34,c Bf_H = 40, c Ar_L =200,c Ar_H =500,c Br_L = 240,c Br_H =540, the corresponding maintenance time parameter t Af_H =0.2,t An_H =0.05,t Bf_H =0.12,t Bn_H =0.03,t Ar_H =0.4,t Br_H = 0.3. P i A (k) and P i B (k) is a random distribution on [0,1] and remains constant in the same set of simulations.

[0102] By comparison, the optimal parameter m can be found * = 1 and N * =6, the optimal expected cost rate is 368.69. The optimization method described takes into account the downtime loss expectation E du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com