Intelligent and full-automatic-material-replenishing stirring dough maker

A kind of dough mixer, fully automatic technology, applied in the direction of dough mixer, structural parts of mixing/kneading machinery, baking, etc., can solve the problem of manual, dough mixer can not meet the continuous dough supply, etc., to achieve better mixing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

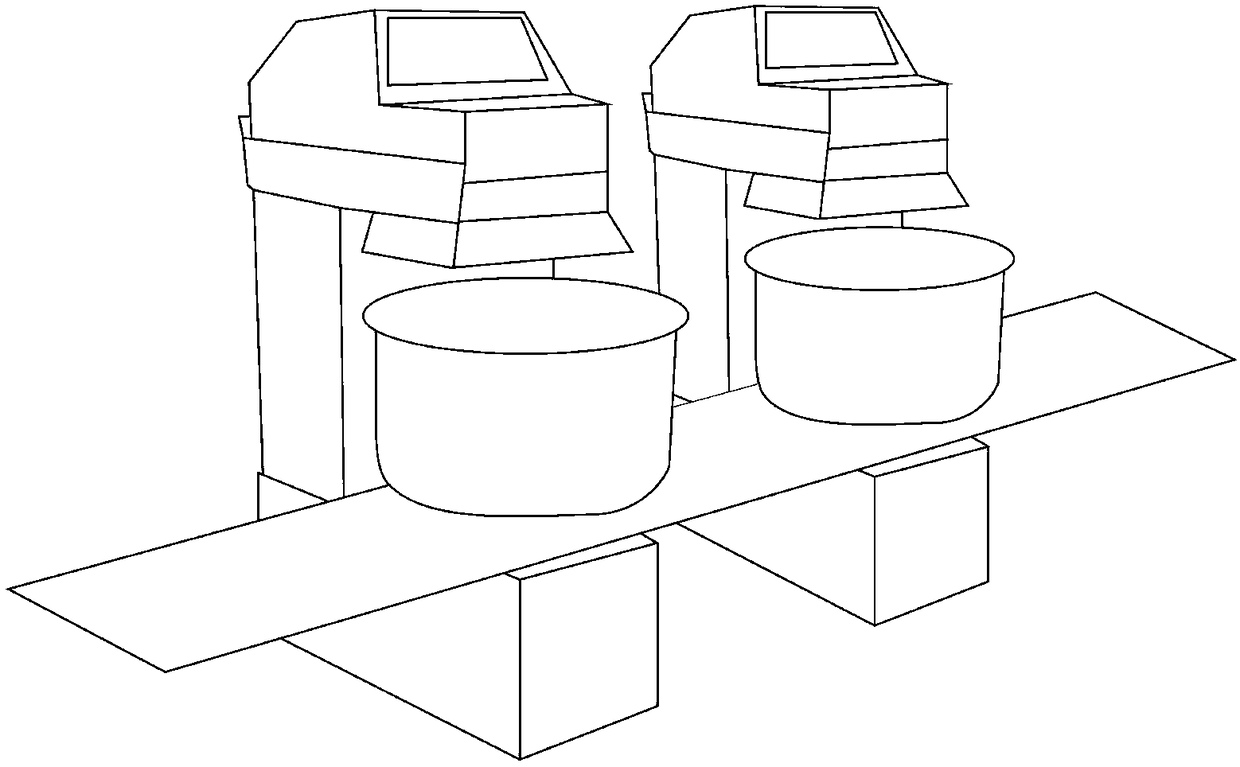

[0011] as attached figure 1 shown

[0012] The present invention provides an intelligent, fully automatic mixing and kneading machine, comprising: a PLC controller, a mixing tank, a mixing tank, a transmission device, a frequency conversion motor, a first-level stirring base, a second-level stirring base, Stirring, the transmission device is provided with a transmission base, the mixing cylinder is arranged on the transmission base of the transmission device, the positions of the first-level stirring machine base and the second-level stirring machine base are placed in parallel, and the first-level The hook stirring base and the secondary stirring base are provided with discharge nozzles, and the PLC controller controls the start and stop of the frequency conversion motor, the switch of the discharge nozzles of the primary stirring base and the secondary stirring base.

[0013] A further setting of the present invention is that: the number of the secondary hook stand is great...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com