Topping protection tool and manufacturing method thereof

A production method and tooling technology, which is applied in the field of protective tooling for wheel color registration and spraying, can solve the problems of difficult template making, difficult positioning, inconvenient marking and pasting, etc., and achieves the advantages of easy use, accurate color registration, and low cost of reuse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] Product Example

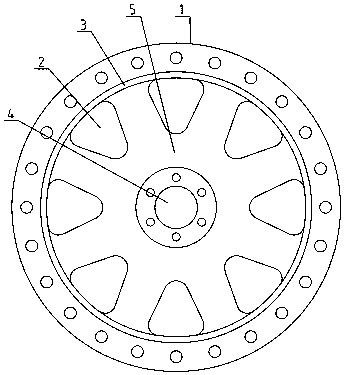

[0023] Such as figure 1 As shown, a kind of overlay protective tooling includes a hub 1 and a hub window protective plate 2 that conforms to the shape of the hub window of the hub 1, and the hub window protective plate 2 can be tightly attached to the hub of the hub 1 by pressing On the window, it also includes a rim protection ring 3 matching the shape of the wheel rim side elevation of the wheel hub 1, a central hole protection plug 4 matching the center hole of the wheel hub 1, and a spoke shape of the wheel hub 1. Matching spoke protection plate 5, the rim protection ring 3 can be tightly attached to the rim side elevation of the wheel hub 1 by extrusion, and the center hole protection plug 4 is inserted into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com