A method for automatic printing color registration by using non-automatic color registration marking plate roller

An automatic printing and color registration technology, which is applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problems that the automatic color registration method cannot be used, time-consuming and labor-intensive, and there are a lot of problems, so as to reduce the scrap rate, avoid mutual overlap, The effect of improving the economic efficiency of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

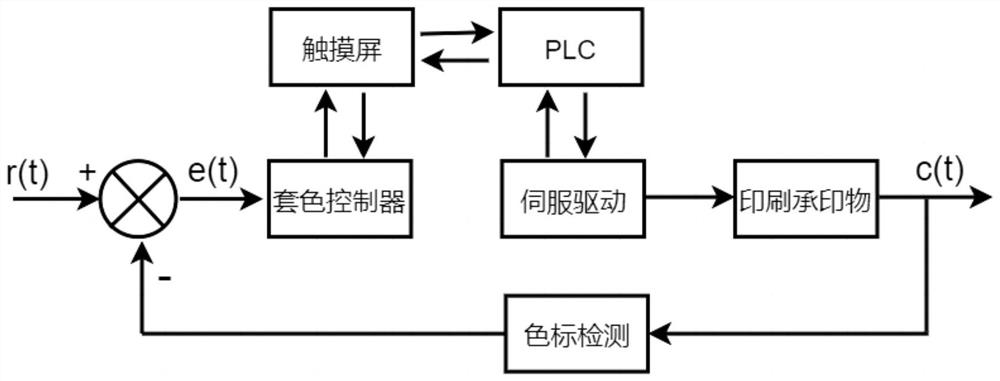

[0028] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

[0029] The method for automatic printing and color registration provided by the present invention by utilizing the non-automatic color registration marking plate roller comprises the following steps:

[0030] 1) Carve a short line parallel to the axis of the plate roller in the blank space at one end of the plate roller of the first color group as the color mark line; the recommended line width of the color mark line is 1-1.5 mm, and the length is recommended to be 10 mm. The recommended distance is greater than or equal to 20mm;

[0031] Encoders are fixedly installed on the motors of each color group roller; starting from the second color group roller, a photoelectric eye is installed at the discharge position of each color group roller; the installation position of each photoelectric eye should be consistent with the printed color Corresponding to the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com