Image chromatography printing control method and device, equipment and storage medium

A technology for printing control and color registration, applied in printing devices, copying/marking methods, printing, etc., can solve problems such as inaccurate color registration, achieve accurate color registration, and improve the effect of image printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

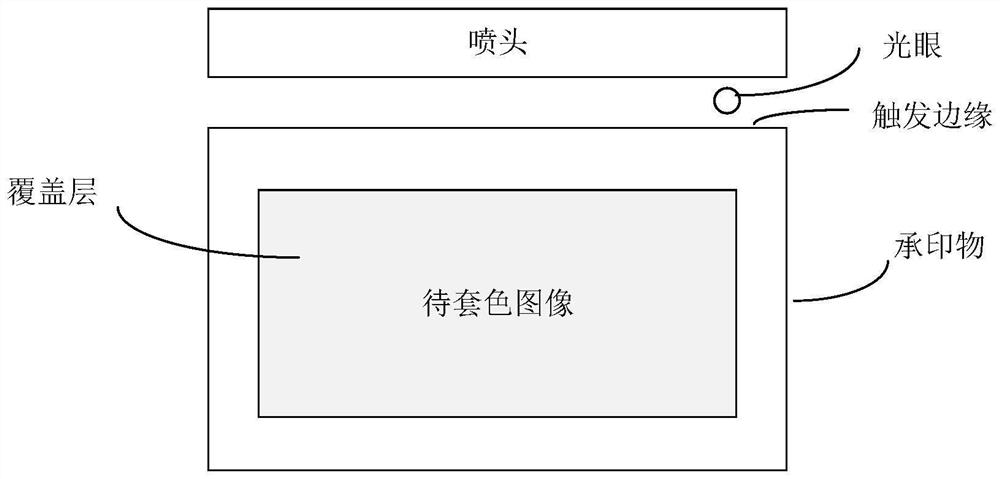

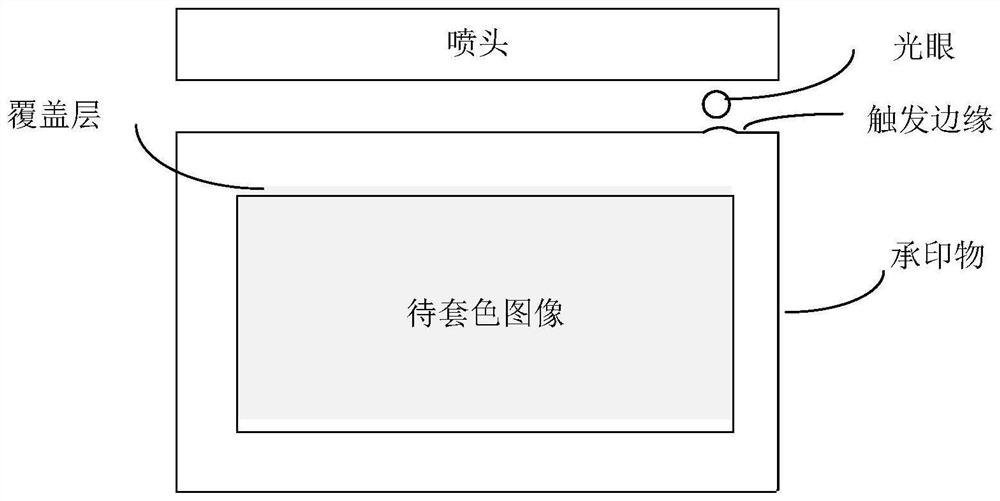

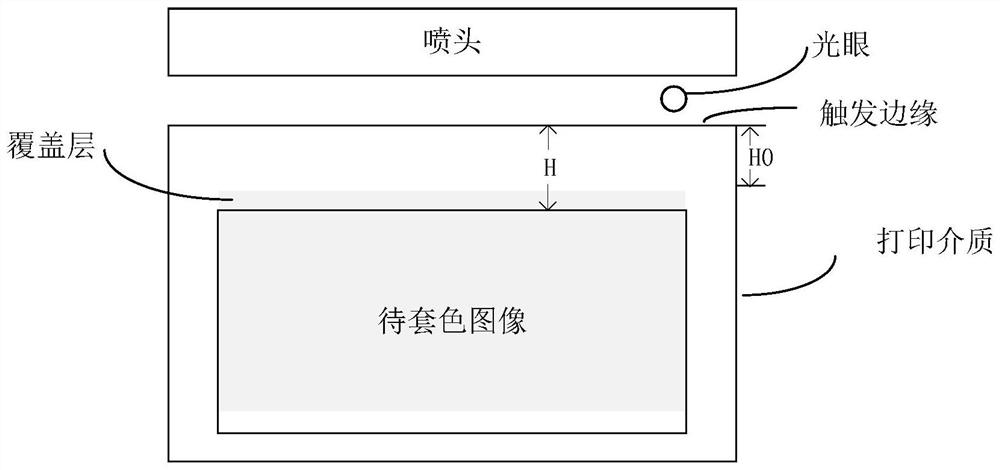

[0062] An embodiment of the present invention provides a method for controlling image registration and printing, and the method is suitable for a varnish machine, a bronzing machine, or a printing device with varnish or bronzing printing. These devices spray varnish or bronzing ink onto the image that has been printed on the substrate (hereinafter referred to as the image to be registered), so that the image to be registered will appear brighter or have special effects such as 3D. However, when the distance between the triggering edge of the substrate and the edge of the image to be registered is inconsistent with the triggering distance in actual printing, it is necessary to automatically adjust the triggering distance to ensure accurate registration of varnish, hot stamping and other covering layers.

[0063] See figure 2 , the image registration and printing control method specifically includes the following steps:

[0064] S1: Obtain the trigger edge of the substrate, wh...

Embodiment 2

[0092] Based on the first embodiment above, the embodiment of the present invention also proposes an image restoration method. In some printing applications, some images have faded or missing part of the image due to some reasons. When repairing is required, color or black and white ink such as CMYKW can be used on the surface of the remaining image to supplement and print the missing part; Print a layer of transparent varnish and other ink on the repaired image to restore the image or improve the image effect. This image restoration method can be applied to some scenes of cultural relics restoration.

[0093] The image restoration method is specifically,

[0094] Obtain the repaired area of the image to be repaired;

[0095] generating repaired image print data according to the repaired area;

[0096] Acquiring the trigger edge of the substrate, wherein the trigger edge is used to trigger the spray head to move the preset trigger distance relative to the substrate to eje...

Embodiment 3

[0106] see Figure 7 , the embodiment of the present invention provides an image registration printing control device 200, the device 200 includes:

[0107] The trigger edge acquisition module 201 is used to acquire the trigger edge of the substrate, wherein the trigger edge is used to trigger the nozzle to move the preset trigger distance relative to the substrate to eject ink to the surface of the substrate, and the surface of the substrate has a color to be registered image;

[0108] An image edge acquisition module 202, configured to acquire an image edge to be registered adjacent to the trigger edge;

[0109] A sampling point acquisition module 203, configured to select several pixel points from the pixels on the edge of the image to be registered as sampling points;

[0110] Sampling distance acquisition module 204, configured to acquire the distance between the sampling point and the trigger edge, denoted as sampling distance;

[0111] An actual trigger distance acqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com