Soldering iron tip cleaner

A cleaner, soldering iron technology, applied in soldering irons, welding equipment, metal processing equipment and other directions, can solve the problem of labor and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] for the manner in which the invention is carried out

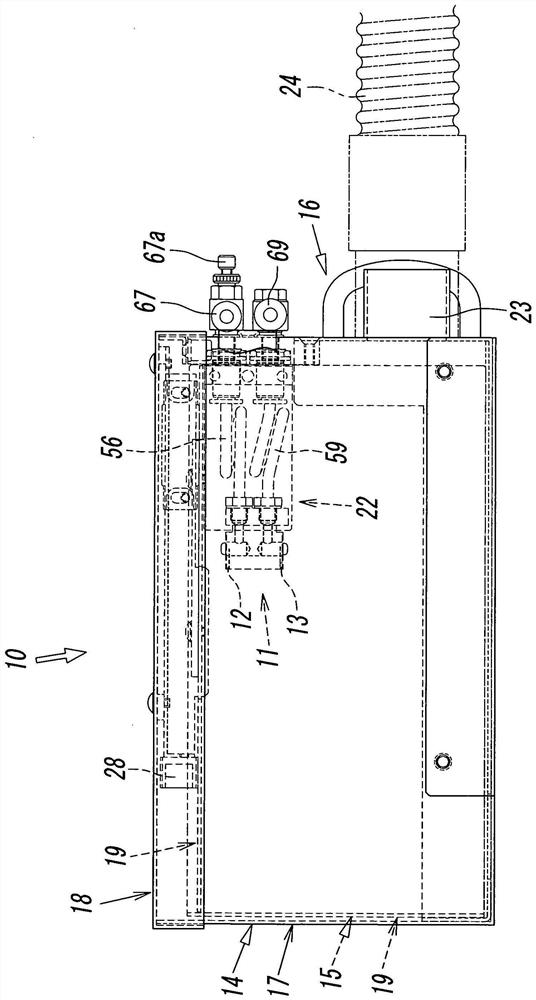

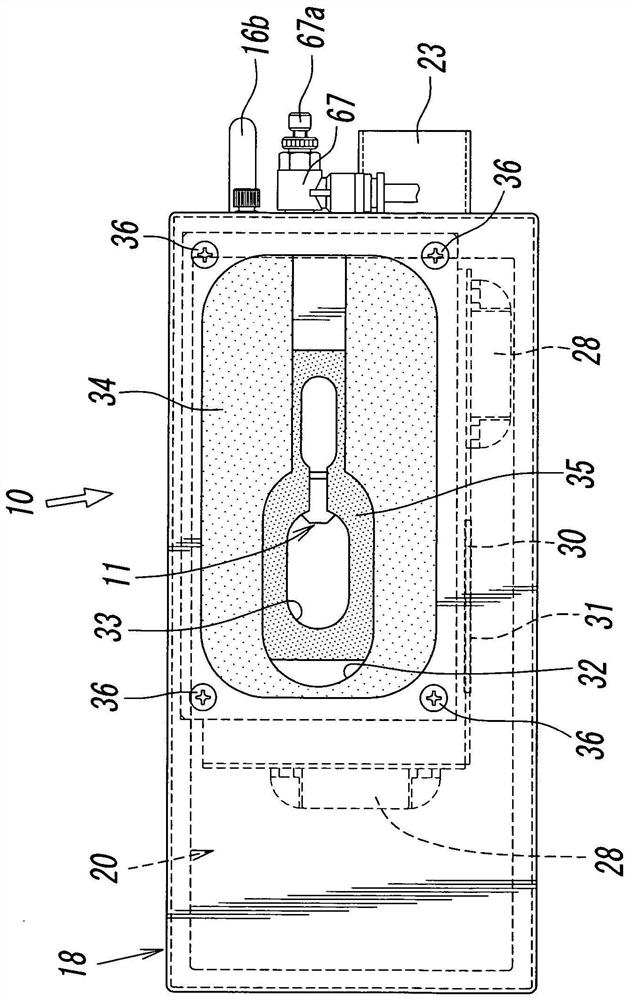

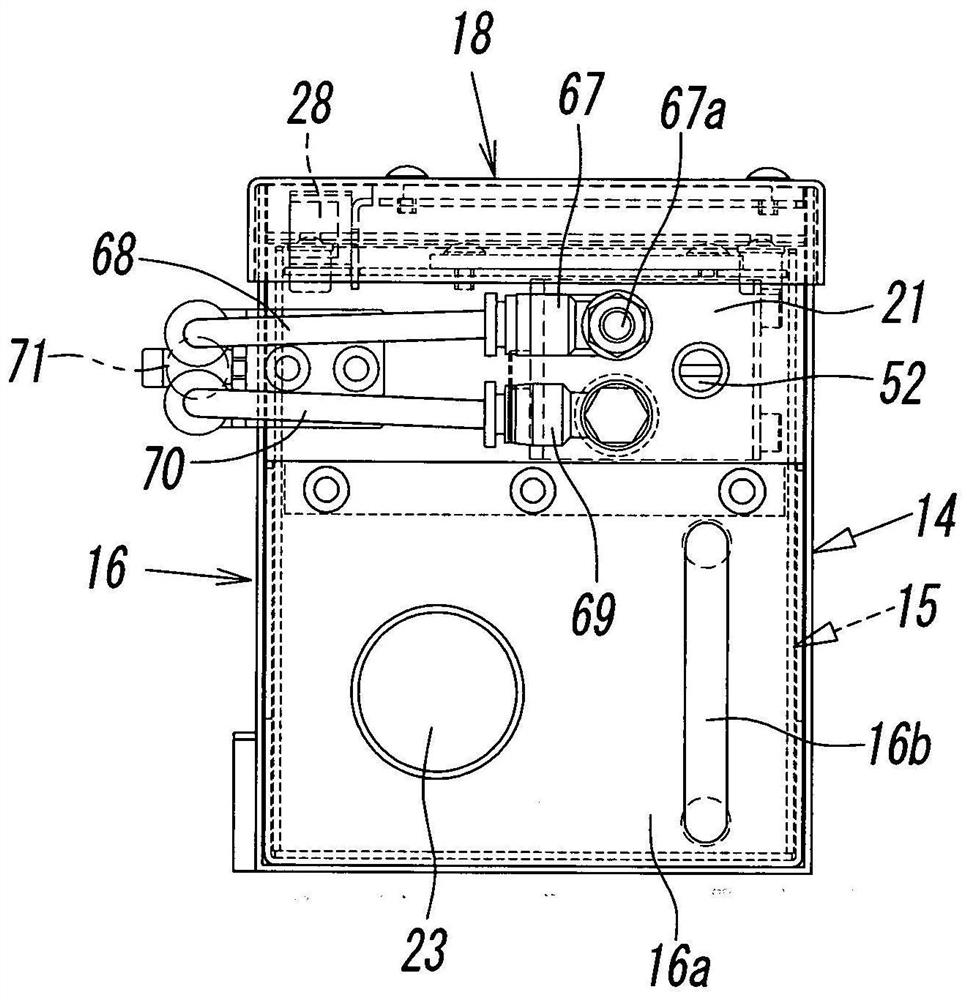

[0037] Figure 1 ~ Figure 3 It is a figure which shows one Embodiment of the soldering iron tip cleaner concerning this invention. This soldering iron tip cleaner, such as Figure 14 and Figure 15 Shown is a cleaner for cleaning the soldering iron tip 1a of a soldering iron 1 adhered to solder slag by spraying air, and has a cleaner box 10 with an air blowing area inside; it is arranged inside the cleaner box 10 The nozzle member 11; and the first nozzle hole 12 and the second nozzle hole 13 opened at the upper and lower end positions of the front end surface of the nozzle member 11.

[0038] The first nozzle hole 12 is a nozzle hole for peeling off the solder slag attached to the soldering iron tip 1a of the soldering iron 1 by spraying air, and the second nozzle hole 13 is used for peeling off the solder slag from the soldering iron tip 1a by spraying air. The peeled-off solder slag falls to the nozzle hole at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com