Fuel spraying device

A fuel injection device and fuel injection technology, applied in the direction of fuel injection devices, fuel injection pumps, low-pressure fuel injection, etc., can solve the problems of increased frequency, fuel injection volume error, engine rotation instability, etc., and achieve the purpose of suppressing torque Changes, reliable fuel suction, and the effect of preventing instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

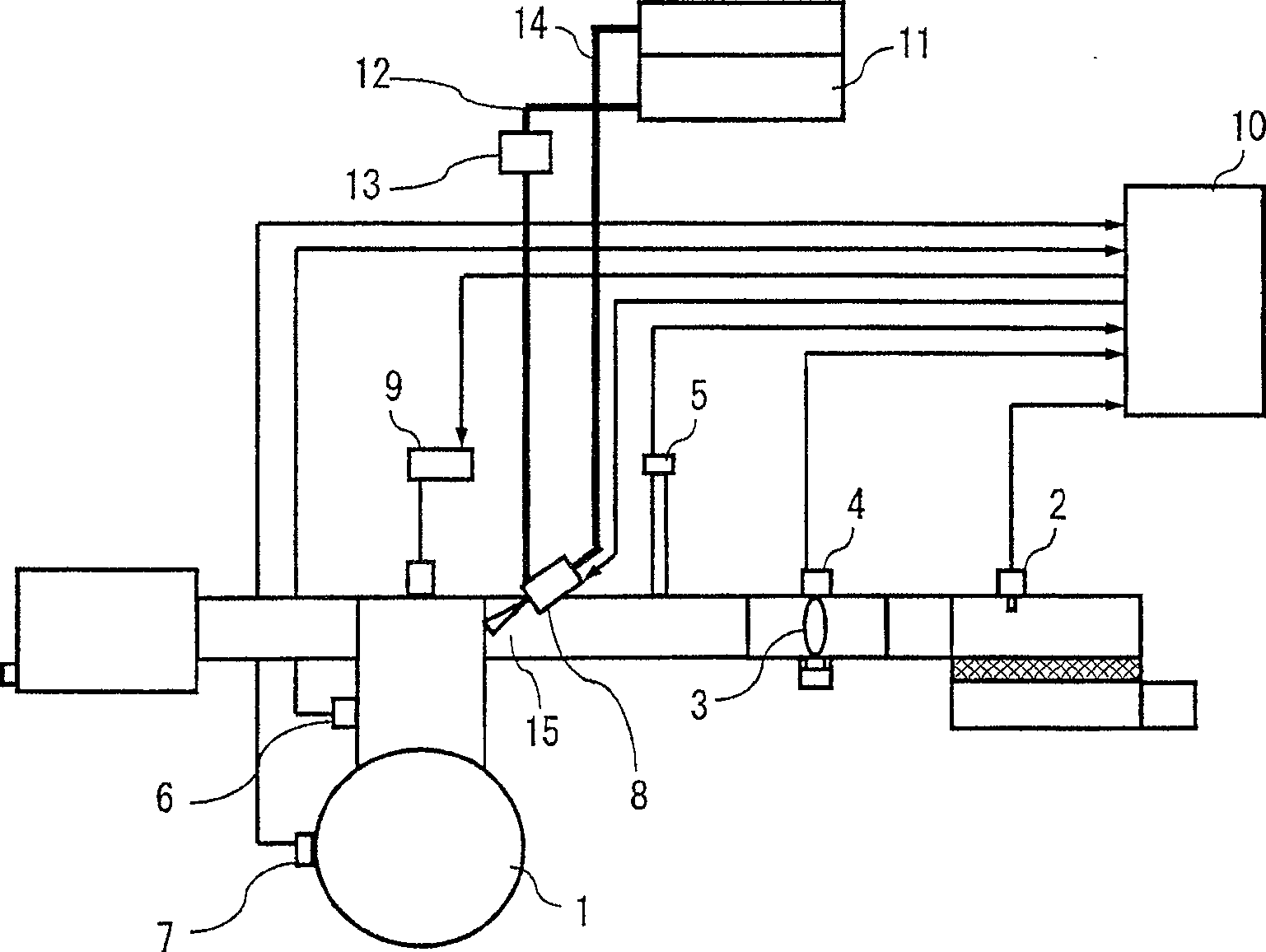

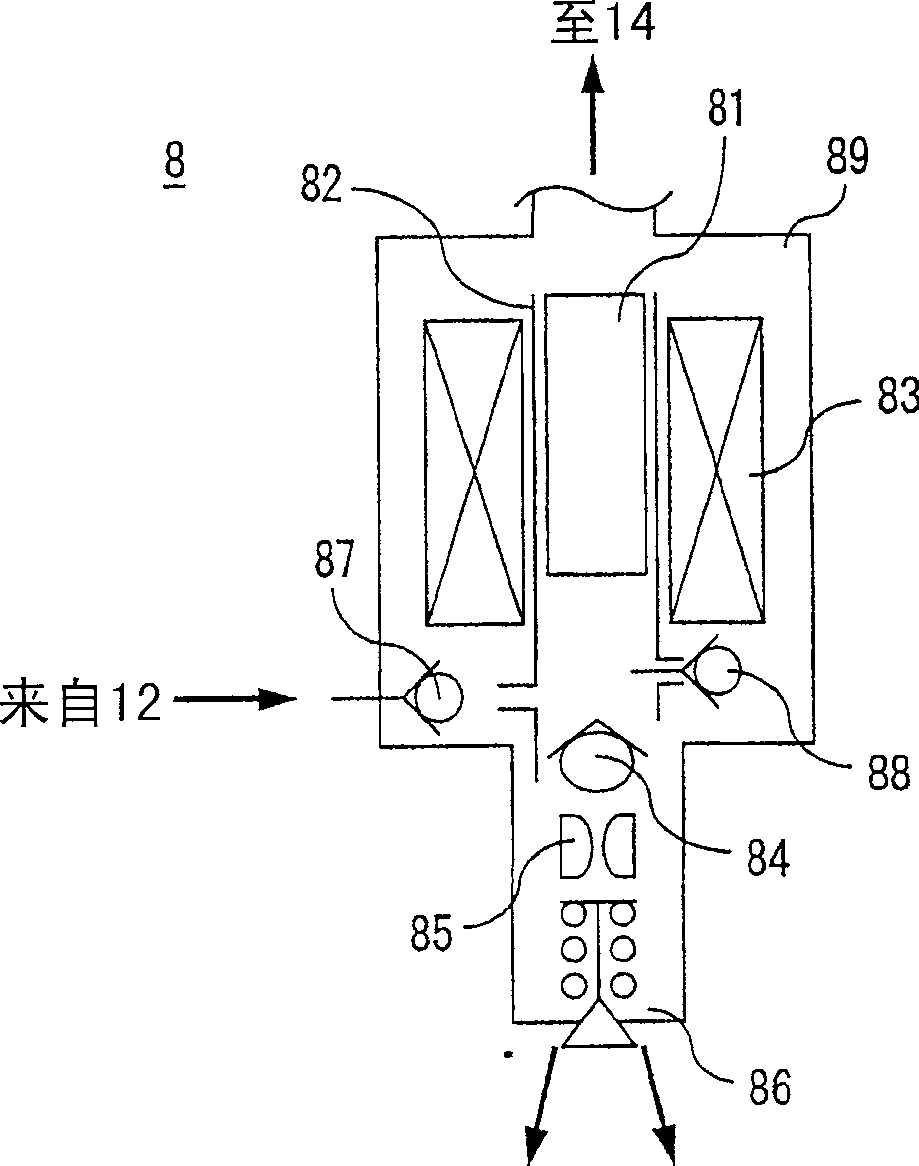

[0035] figure 1 It is a schematic configuration diagram showing the state in which the fuel injection device of the present invention is mounted on the engine in the first embodiment.

[0036] figure 1 Among them, symbol 1 is a four-stroke engine, 2 is an intake air temperature sensor that detects the intake air temperature of engine 1, 3 is a throttle valve, and 4 is a throttle opening sensor that detects the opening degree of throttle valve 3 , 5 is an intake pressure sensor that detects the intake pressure on the downstream side of the throttle valve 3, 6 is an engine temperature sensor that detects the wall surface temperature of the engine 1, and 7 is a crankshaft rotation of the engine 1 (not shown). The crankshaft angle sensor for position detection, 8 is the fuel injection assembly, 9 is the ignition coil, 10 is the control unit.

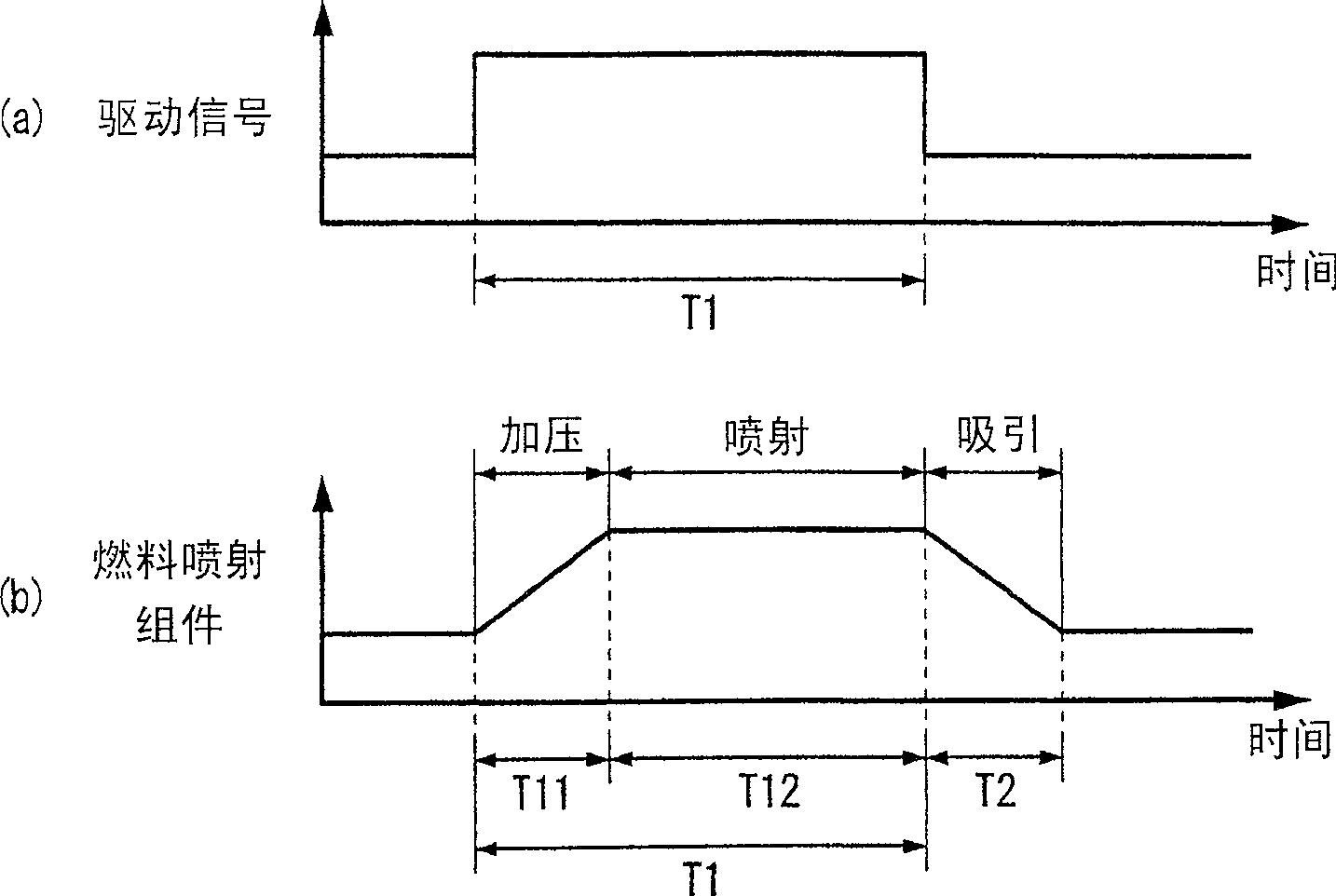

[0037] The fuel injection assembly 8 injects fuel into an intake manifold 15 connected to the engine 1 . Also, the control unit 10 cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com