Coloring nozzle and coloring unit including the same

A nozzle and coloring technology, which is applied in the direction of electrical components, circuits, marking conductors/cables, etc., can solve the problems that the toner is difficult to spray into mist, it is difficult to spray toner, and it is not suitable for intermittent spraying. Effects of simplifying and preventing nozzle clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

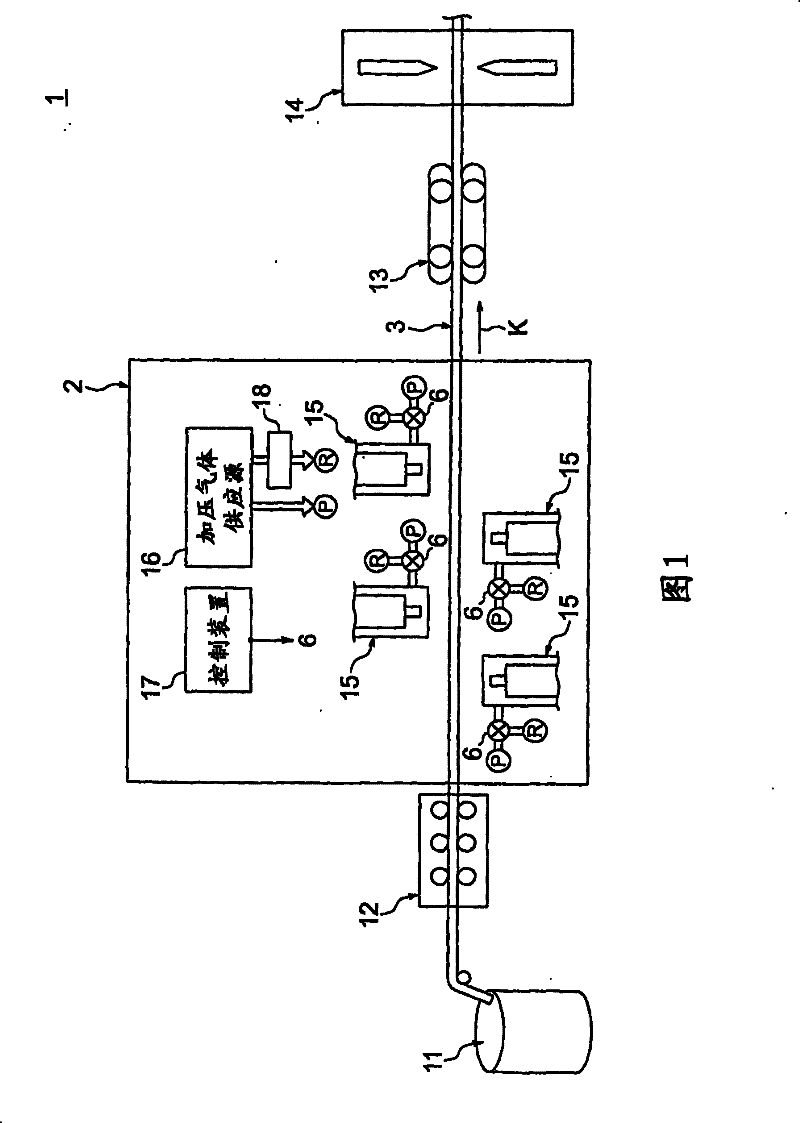

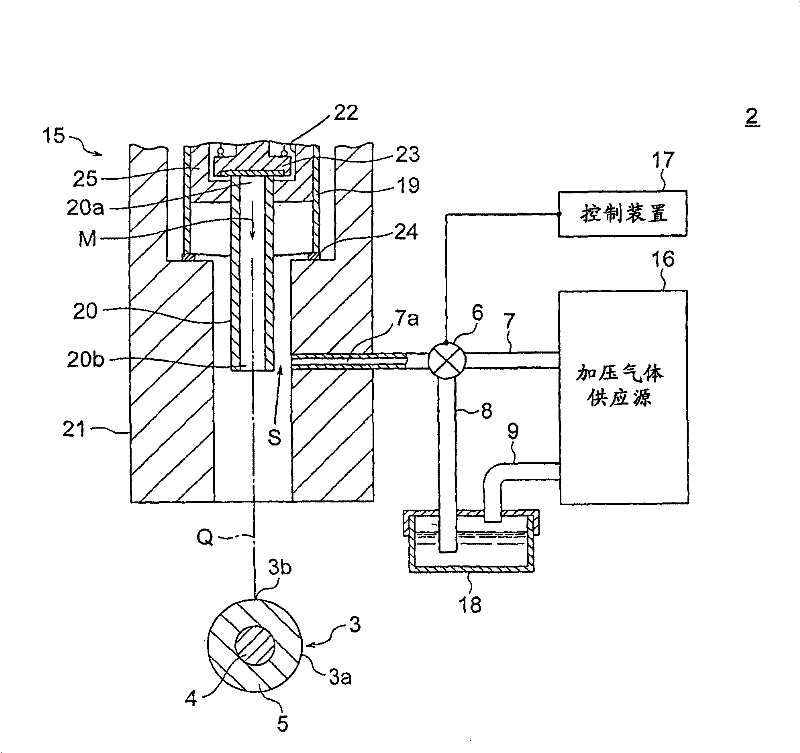

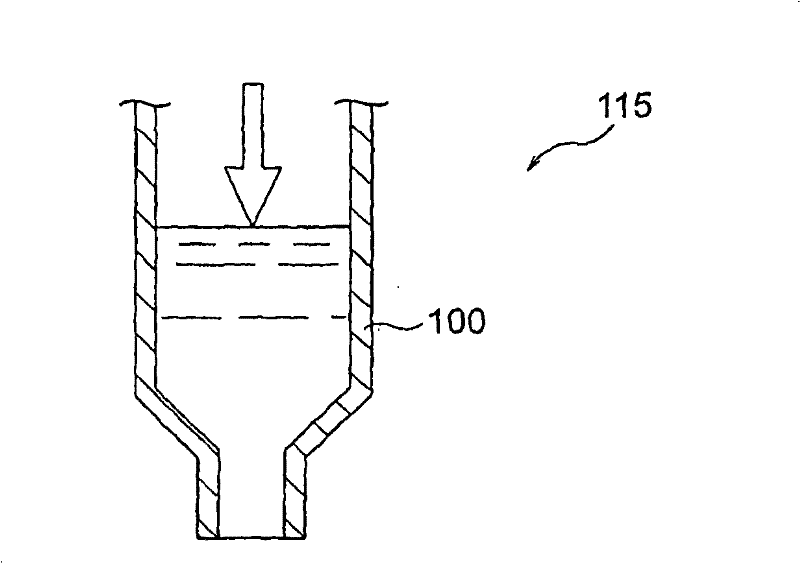

[0044] The following will combine figure 1 and 2 A wire coloring device (hereinafter referred to as "coloring device") including a coloring unit having a coloring nozzle according to a preferred embodiment of the present invention will be described. This coloring apparatus 1 cuts an electric wire 3 as an article into a predetermined length, and paints the outer surface 3a of the wire 3 over the entire periphery. That is, the coloring device 1 colors or marks the outer surface 3 a of the wire 3 .

[0045] The wire 3 constitutes a wire harness to be mounted on an automobile as a mobile device. like figure 2 As shown, each wire 3 includes a conductive core wire 4 and an insulating coating 5 . A plurality of elementary wires are wound together to form the core wire 4 . Each base wire is made of conductive metal. Alternatively, the core wire can also be formed from only one basic wire. The coating 5 is made of synthetic resin such as polyolefin. Polyolefins are not easy t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com