Welding fixture of high voltage potential fixing plate

A technology for welding tooling and fixing plates, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of welding precision, difficult positions, and low welding efficiency, so as to avoid manual support of terminals, facilitate welding, Soldering Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] Such as Figure 4-5 As shown, the high-voltage potential fixing plate 2 is circular, and the outer wall of the fixing plate 2 is provided with a plurality of screw-shaped terminals 21, and the fixing plate 2 is provided with an axial gap 22;

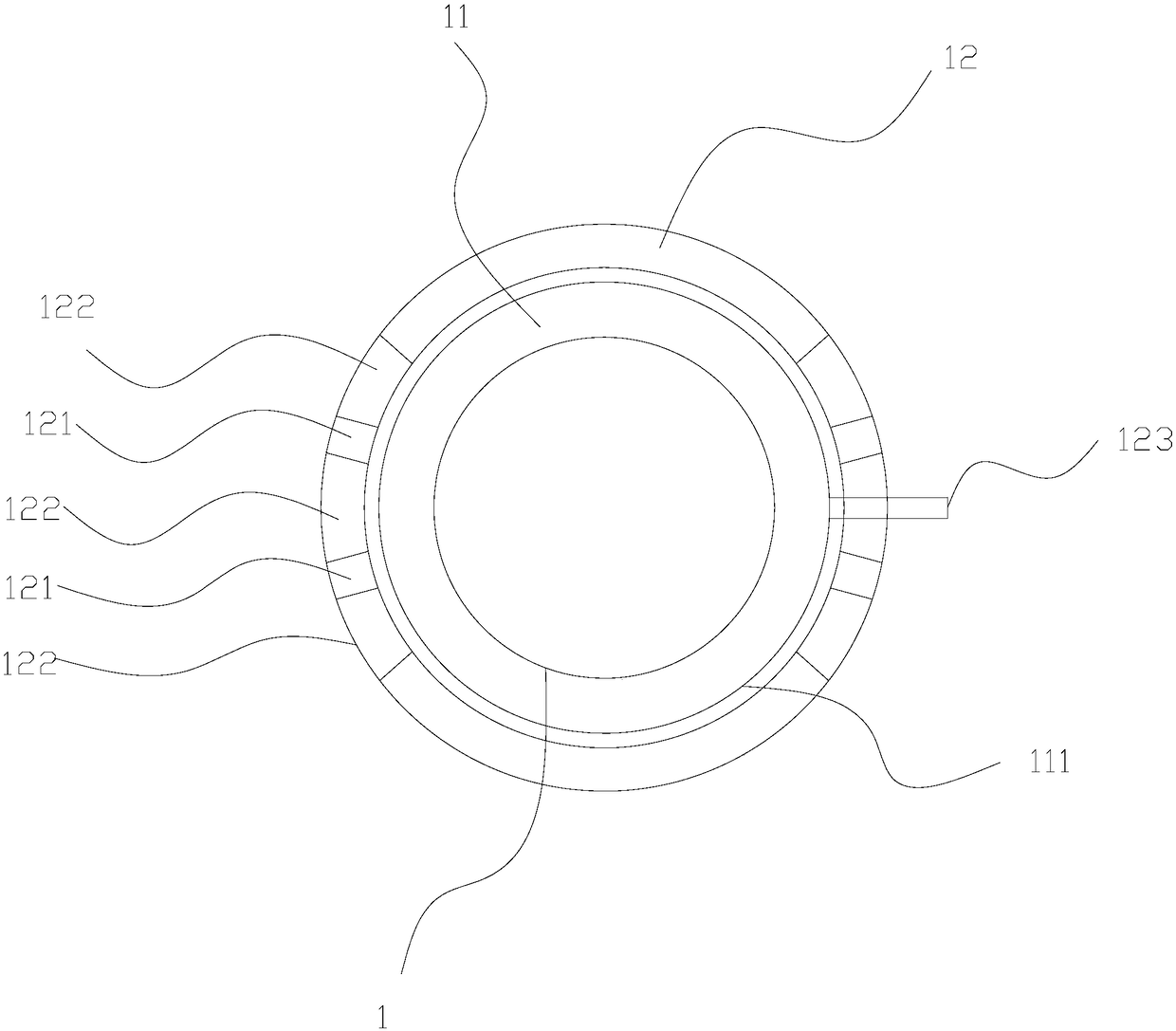

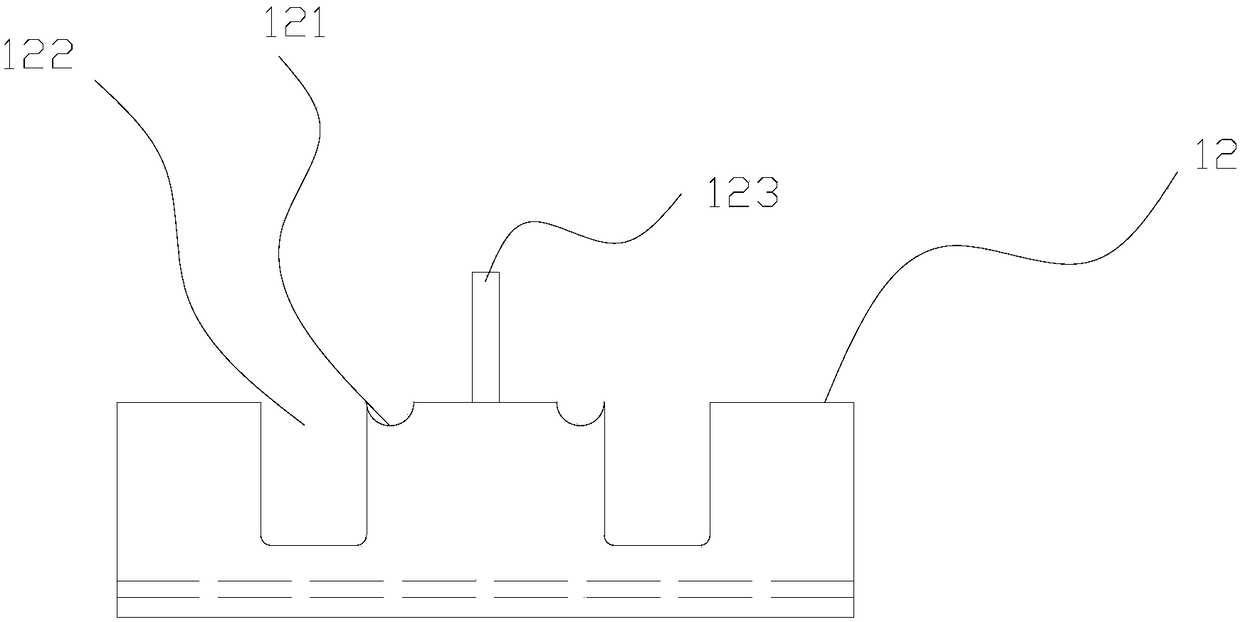

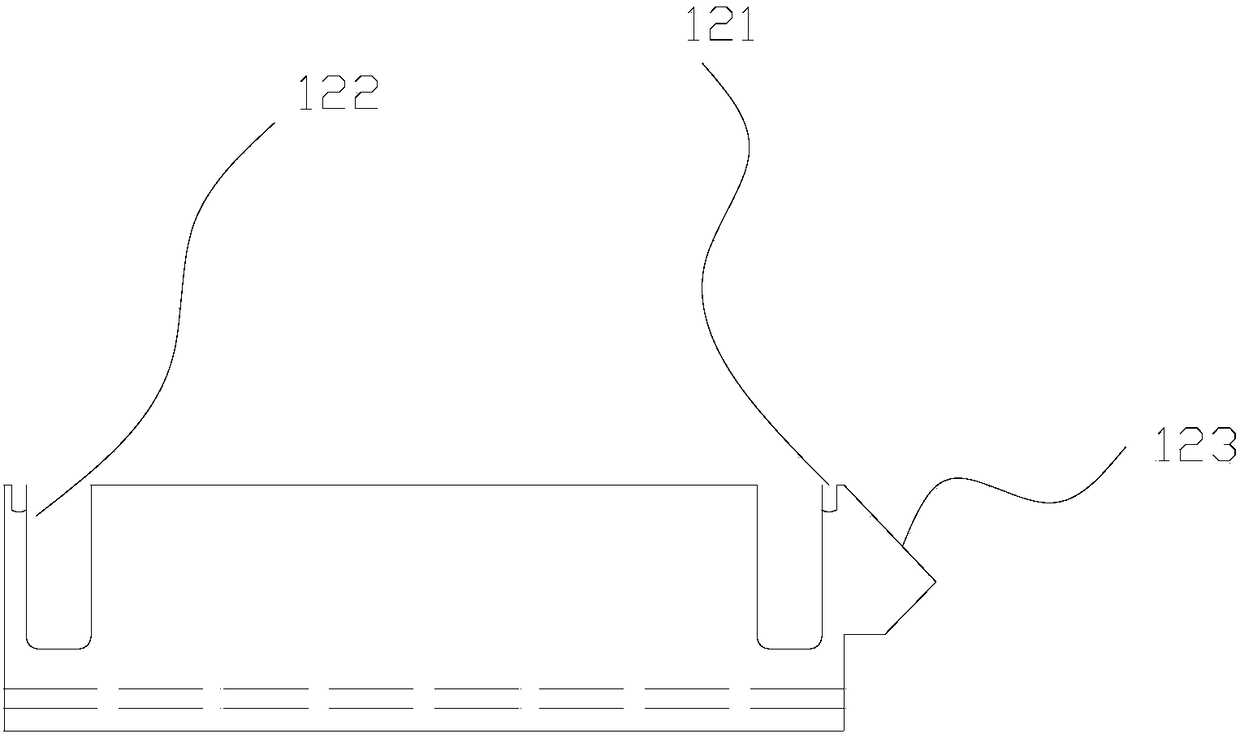

[0019] The present invention as Figure 1-3 As shown, the welding tooling of the high-voltage potential fixing plate includes a tooling body 1, and the tooling body 1 is in the shape of a ring, and the tooling body 1 includes an inner ring 11 and an outer ring 12, and the outer ring 12 is higher than the Inner ring 11; it is convenient to place the fixing plate 1 therein.

[0020] The inner diameter of the outer ring 12 is equal to the outer diameter of the high voltage potential fixing plate 1 ; so that the fixing plate 2 can be just accommodated in the welding tool 1 .

[0021] Groove 1 121 on the outer ring 12 is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com