Automatic braking mechanism

An automatic braking and locking mechanism technology, applied in the hoisting device and other directions, can solve the problems of insufficient compact structure, slow response speed of the braking mechanism, poor braking sensitivity and reliability, etc., and achieve high braking sensitivity and reliability , to ensure the effect of balance and torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

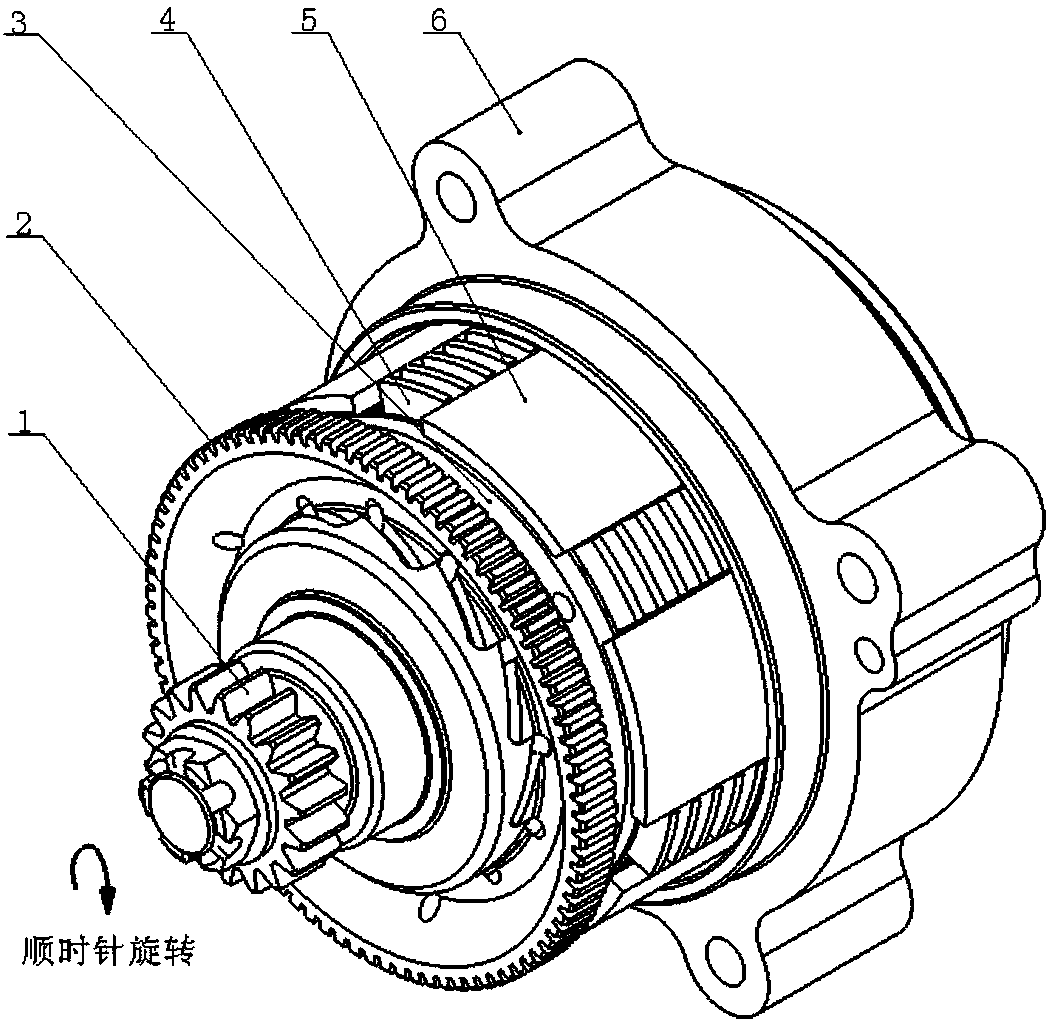

[0024] refer to figure 1 , an automatic braking mechanism, characterized in that it includes an outer locking mechanism 1, an inner locking mechanism 2, an elastic element 3 and a friction pair 4 sequentially installed on the same shaft, and the outer locking mechanism 1 is located in the axial direction Restricted, the inner locking mechanism 2 can move back and forth in the axial direction;

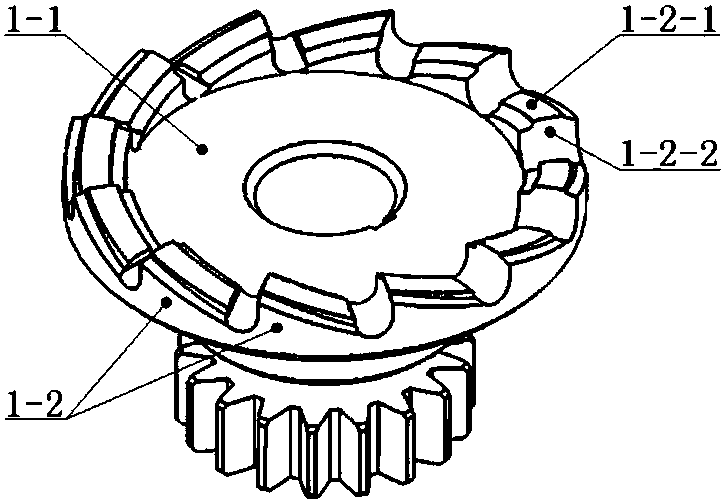

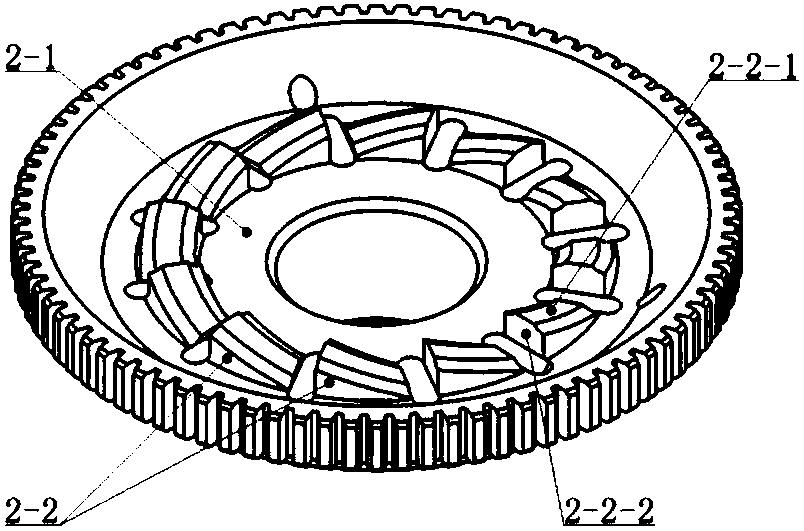

[0025] refer to figure 2 , image 3 , the outer locking mechanism 1 is composed of an outer locking wedge 1-2 and a disc-shaped first base 1-1, the outer locking wedge 1-2 is fixed on the plane of the inner end surface of the base 1-1, and the inner locking The tightening mechanism 2 includes an inner locking wedge 2-2 and a disc-shaped second substrate 2-1, the outer locking wedge 2-2 is fixed on the plane of the second substrate 2-1 outer end face, and the outer locking wedge Block 1-2 cooperates with inner locking wedge 2-2,

[0026] refer to Figure 4 , when the outer locking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com