Ultra-fine-grain ultra-thick steel with yield strength of not less than 480MPa grade, and preparation method

A yield strength, ultra-fine grain technology, applied in the field of metallurgy, can solve the problems of high Ni content of precious metals, high production costs, low Kca value, etc., and achieve the effect of uniform distribution, hindering generation and propagation, and fine grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

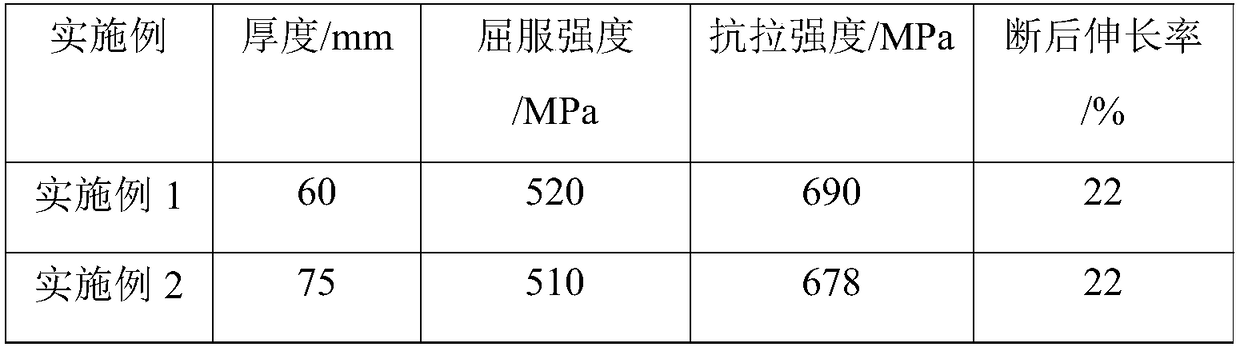

Embodiment 1

[0029] The chemical composition of the 60mm ultra-fine-grained extra-thick steel in this example is as follows: C: 0.08%, Si: 0.25%, Mn: 1.60%, P: 0.015%, S: 0.003%, Al: 0.01%, Cr: 0.22% , Mo: 0.25%, Nb: 0.03%, V: 0.04%, Ti: 0.018%, the rest is Fe and unavoidable impurities, of which H≤0.0003%.

[0030] The slab is slowly cooled to below 300°C, the thickness of the slab is 300mm, and a three-stage heating process is adopted. The first stage: the temperature in the preheating section is set at 700-850°C; the second stage: it is divided into heating 2-1 section and heating 2- 2 sections, heating 2-1 section temperature setting 1050-1200 ℃, heating 2-2 section temperature setting 1180-1230 ℃; third section: furnace gas temperature setting of 1150-1200 ℃ in the soaking section; heat storage Type heating furnace to 1150℃ for tapping.

[0031] Rolling: The slab comes out of the furnace and is water-cooled in multiple channels by the descaling machine to the surface temperature of t...

Embodiment 2

[0034] The chemical composition of the 75mm ultra-fine-grained extra-thick steel in this example is as follows: C: 0.11%, Si: 0.10%, Mn: 1.20%, P: 0.010%, S: 0.002%, Al: 0.03%, Cr: 0.10% , Mo: 0.18%, Nb: 0.04%, V: 0.06%, Ti: 0.025%, the rest is Fe and unavoidable impurities, of which H≤0.0003%.

[0035] The slab is slowly cooled to below 300°C, the thickness of the slab is 300mm, and a three-stage heating process is adopted. The first stage: the temperature in the preheating section is set at 700-850°C; the second stage: it is divided into heating 2-1 section and heating 2- 2 sections, heating 2-1 section temperature setting 1050-1200 ℃, heating 2-2 section temperature setting 1180-1230 ℃; third section: furnace gas temperature setting of 1150-1200 ℃ in the soaking section; heat storage Type heating furnace to 1160℃ for tapping.

[0036] Rolling: The slab comes out of the furnace and is water-cooled in multiple channels by the descaling machine to the surface temperature of t...

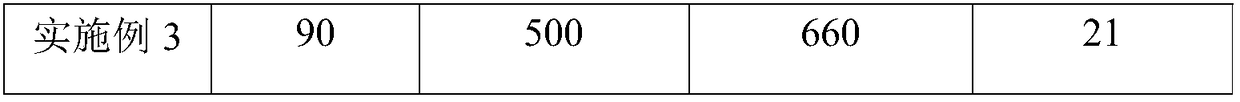

Embodiment 3

[0039] The chemical composition of the 90mm ultra-fine-grained extra-thick steel in this example is as follows: C: 0.07%, Si: 0.40%, Mn: 1.80%, P: 0.008%, S: 0.005%, Al: 0.05%, Cr: 0.30% , Mo: 0.10%, Nb: 0.015%, V: 0.08%, Ti: 0.010%, the rest is Fe and unavoidable impurities, of which H≤0.0003%.

[0040] The slab is slowly cooled to below 300°C, the thickness of the slab is 300mm, and a three-stage heating process is adopted. The first stage: the temperature in the preheating section is set at 700-850°C; the second stage: it is divided into heating 2-1 section and heating 2- 2 sections, heating 2-1 section temperature setting 1050-1200 ℃, heating 2-2 section temperature setting 1180-1230 ℃; third section: furnace gas temperature setting of 1150-1200 ℃ in the soaking section; heat storage Type heating furnace to 1180℃ for tapping.

[0041] Rolling: The slab comes out of the furnace and is water-cooled in multiple channels by the descaling machine to the surface temperature of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com