Transport conversion mode

A technology for transporting vehicles and pivoting, applied in the direction of transportation and packaging, steering rods, steering mechanisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

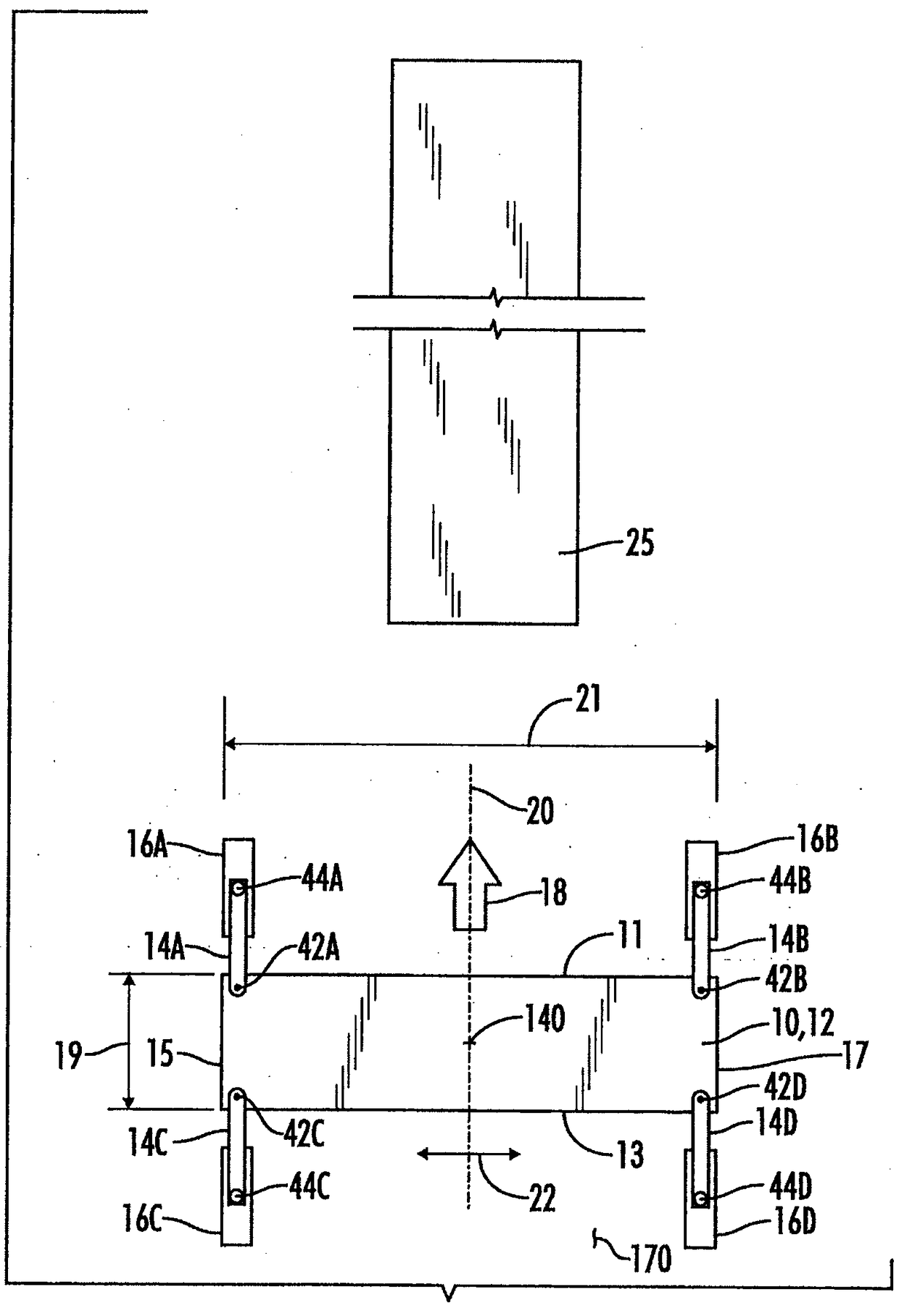

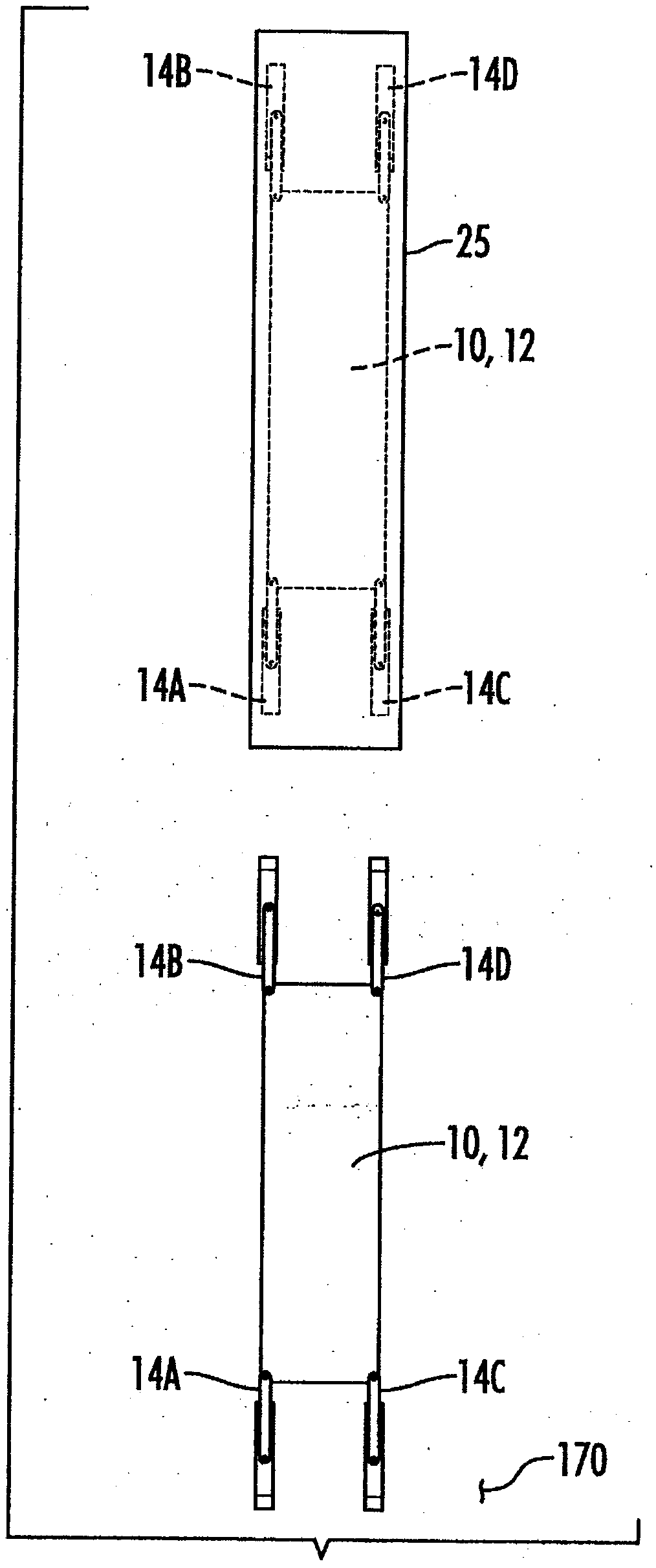

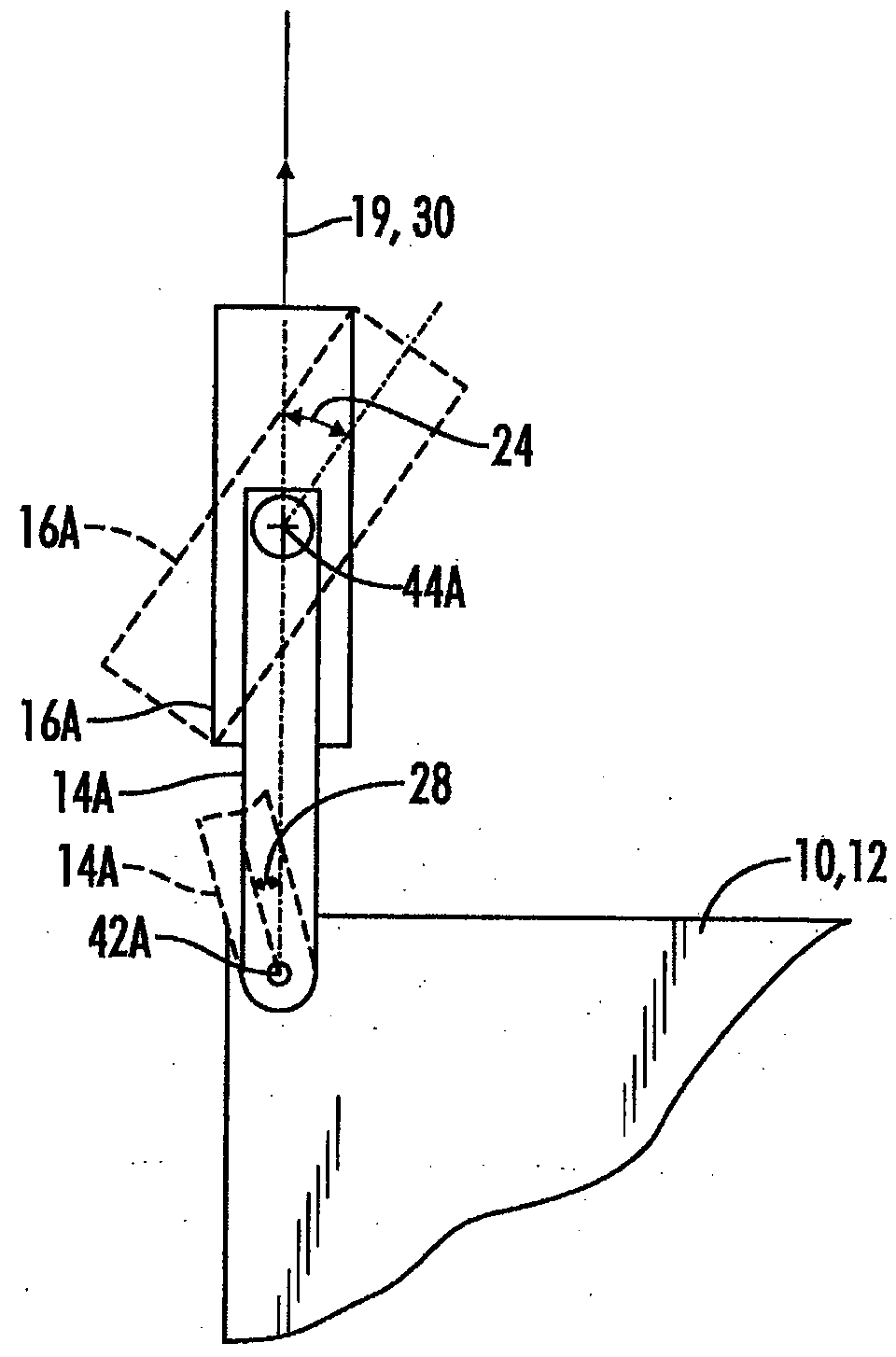

[0041] Figure 1A A self-propelled construction machine 10 is shown schematically. Machine 10 includes a machine frame 12 . The machine frame 12 can be described as having a front 11 , a rear 13 , a left side 15 and a right side 17 . Frame 12 has a frame length 19 defined between front portion 11 and rear portion 13 . The frame 12 has a frame width 21 defined between a left side 15 and a right side 17 .

[0042] Such as Figure 10 As shown schematically in , the construction machine 10 may be a slipform paver having a spreading device 118 arranged to engage concrete blocks 120 formed by a mold 122 such that a formed slab 124 of concrete is slipformed by the machine 10 and laid Exit the rear of Mech 10.

[0043] Figure 10 The slipform paver 10 shown in may be of any conventional construction with respect to its mechanical frame 12 and arrangement of supporting swing legs and tracks. The mechanical frame 12 may be a fixed width frame. The mechanical frame 12 may be a si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com