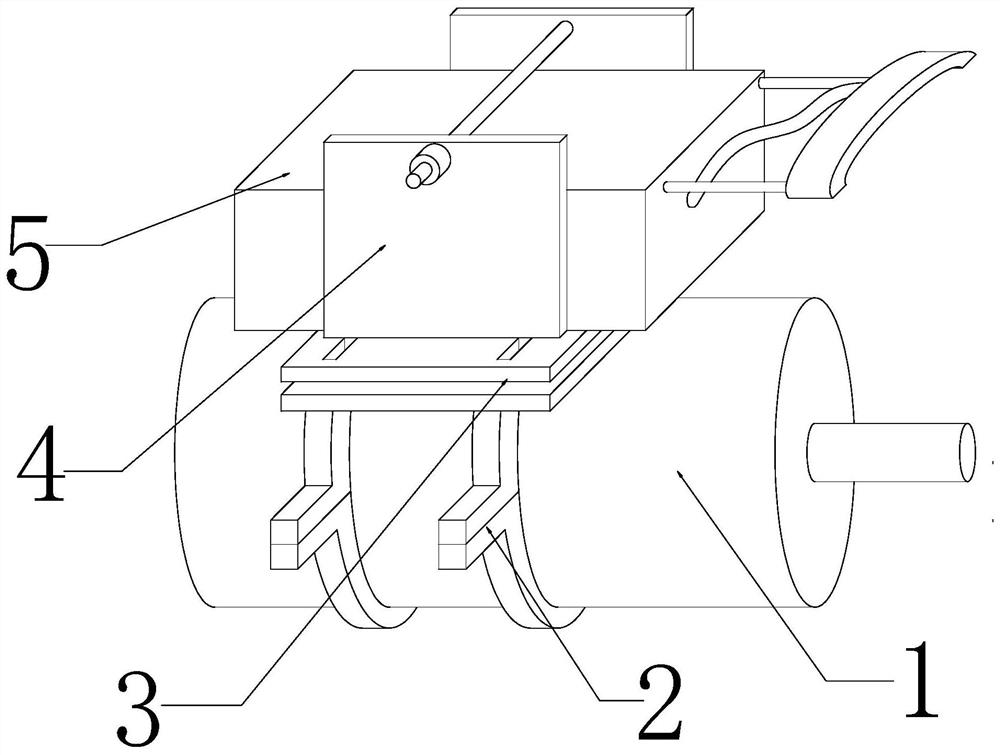

A fully mechanized excavator foam dust suppression device installation mechanism

A technology of a dust suppression device and an installation mechanism, which is applied to slitting machinery, earth-moving drilling, etc., can solve the problems of cumbersome installation operation, shortened service life, time-consuming and laborious, etc., and achieves the solution of cumbersome installation operation, improves stability, and facilitates installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

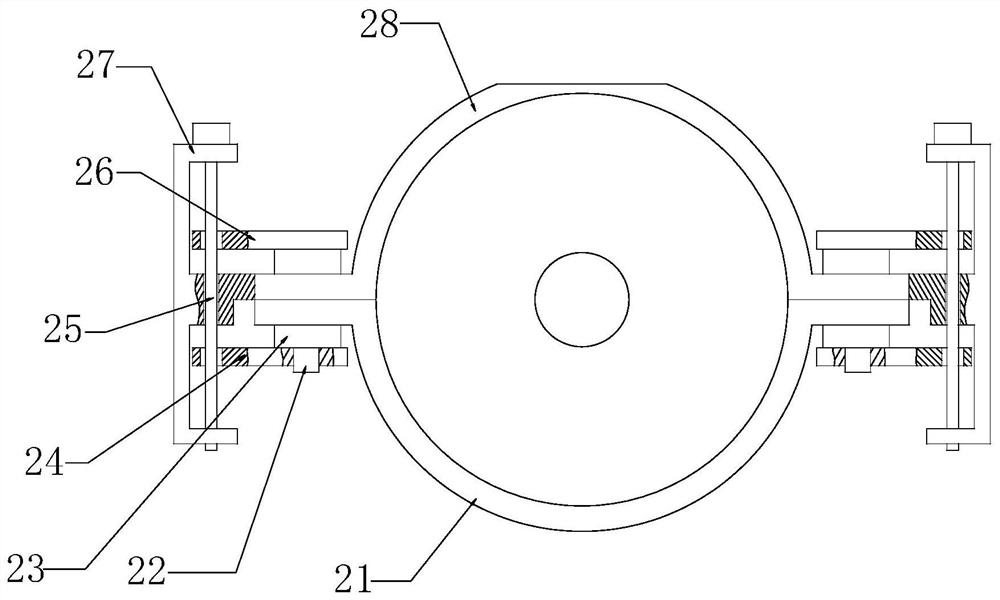

[0025] Specific embodiments: When the staff uses this mechanism, the upper hoop 28 and the lower hoop 21 are respectively assembled on the upper and lower ends of the annular side of the reducer 1, and the upper hoop 28 and the lower hoop 21 are connected by bolts 22, Then tighten the nut 23, and then the staff rotates the turntable, the turntable rotates to drive the two-way screw 25 to rotate, and the ball nut pair converts the rotation of the two-way screw 25 into linear motion, so that the ball nut seat drives the upper splint 26 to move downward, thereby Move the upper splint 26 to a position close to the upper end surface of the bolt 22, and the ball nut seat 2 drives the lower splint 24 to move, so that the lower splint 24 moves to a position close to the lower end surface of the nut 23. This design improves the upper The stability of the connection between the hoop 28 and the lower hoop 21.

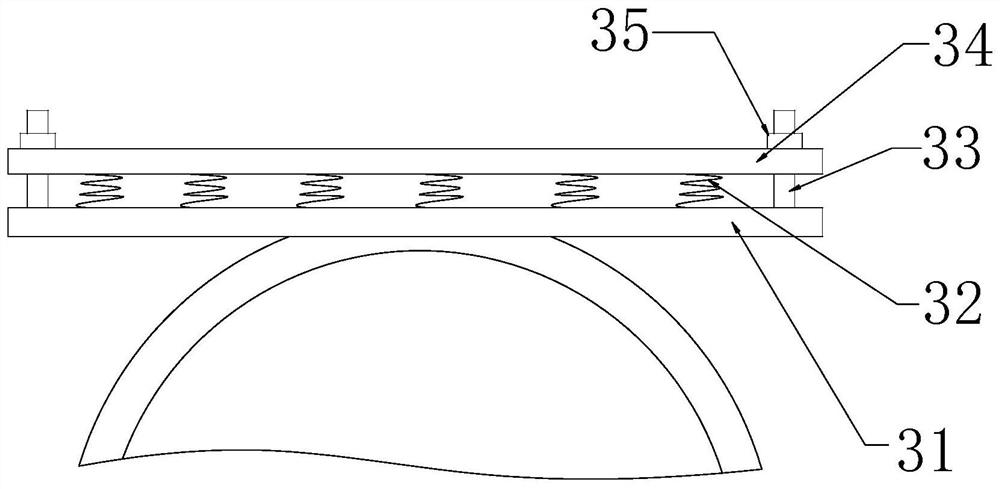

[0026] During the use of this mechanism, the vibration generated by the reducer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com