Low-pressure loss type precession vortex flowmeter spiral flow generator

A precession vortex and spinner technology, which is used in the measurement of flow/mass flow, liquid/fluid solid measurement, volume/mass flow caused by mechanical effects, etc. Increase and other problems, to achieve the effect of wide flow range, simple and compact structure, low pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

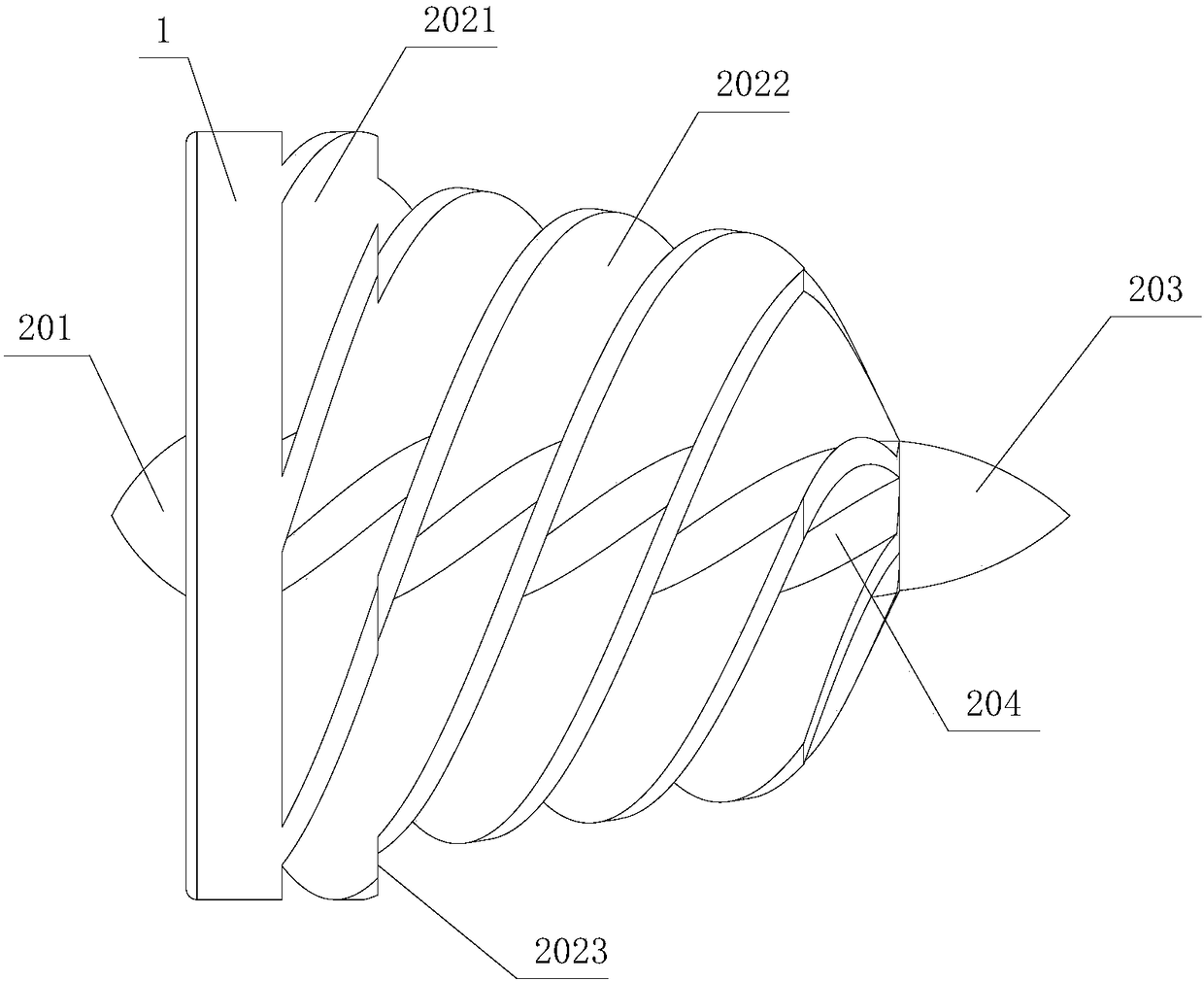

[0029] Embodiment one, refer to Figure 7 , the spinner is installed in the casing of the screw-in vortex flowmeter, and the front end of the spinner of the screw-in vortex flowmeter is a pressure ring 3, which plays the role of pressing the spinner. Specifically, the pressure ring is threaded in the housing, And the end portion presses the fixing ring, so as to realize the pressing and fixing of the spinner.

Embodiment 2

[0030] Embodiment two, refer to Figure 8 , in this embodiment, and there is an external thread on the side wall, when installing, it is directly fixed in the casing of the vortex flowmeter by threading, reducing the Figure 7 The pressure ring in this embodiment reduces parts and is convenient and quick to install. In order to achieve better strength and reliability, the axial width of the fixing ring in this embodiment can be appropriately enlarged or reduced.

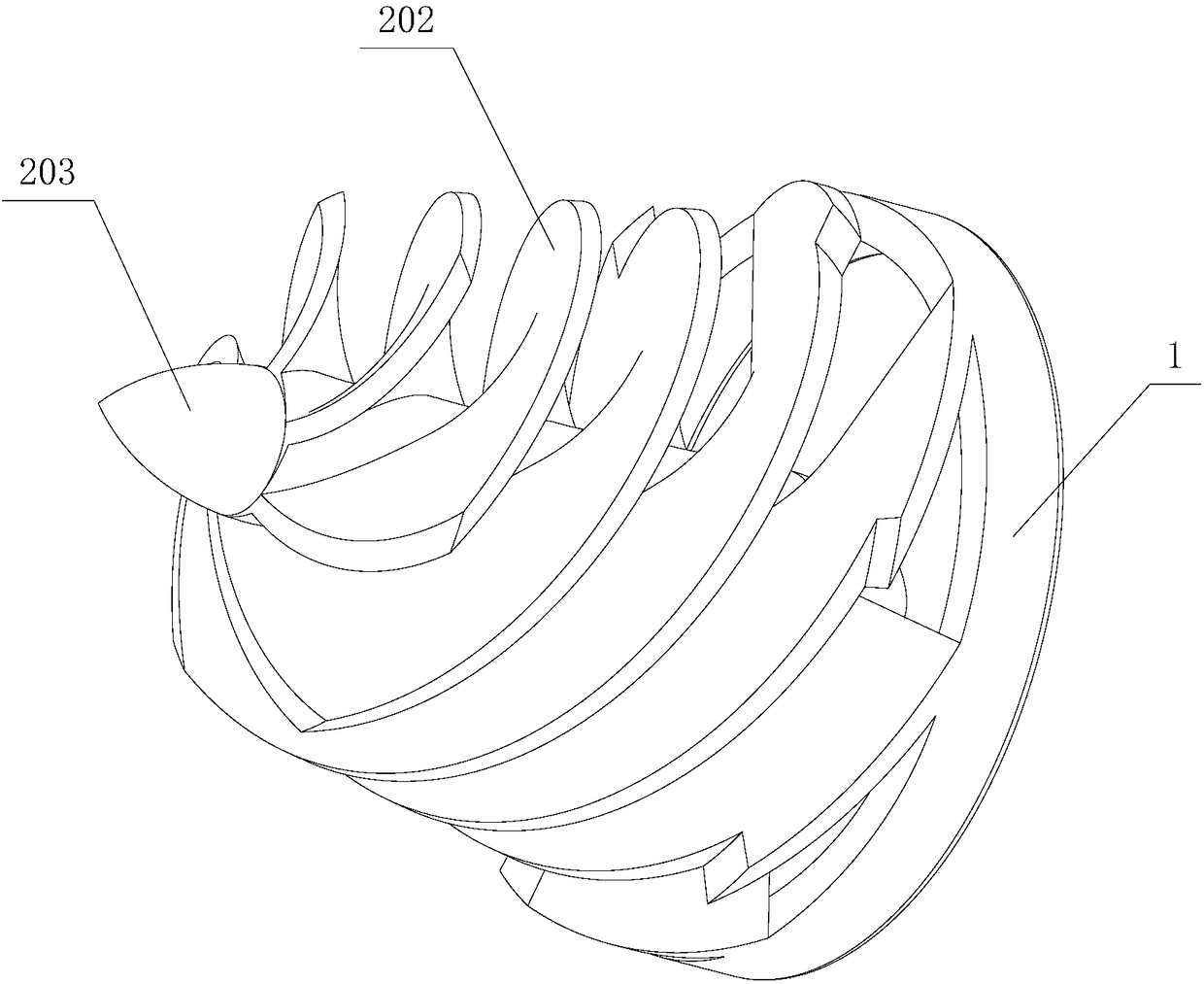

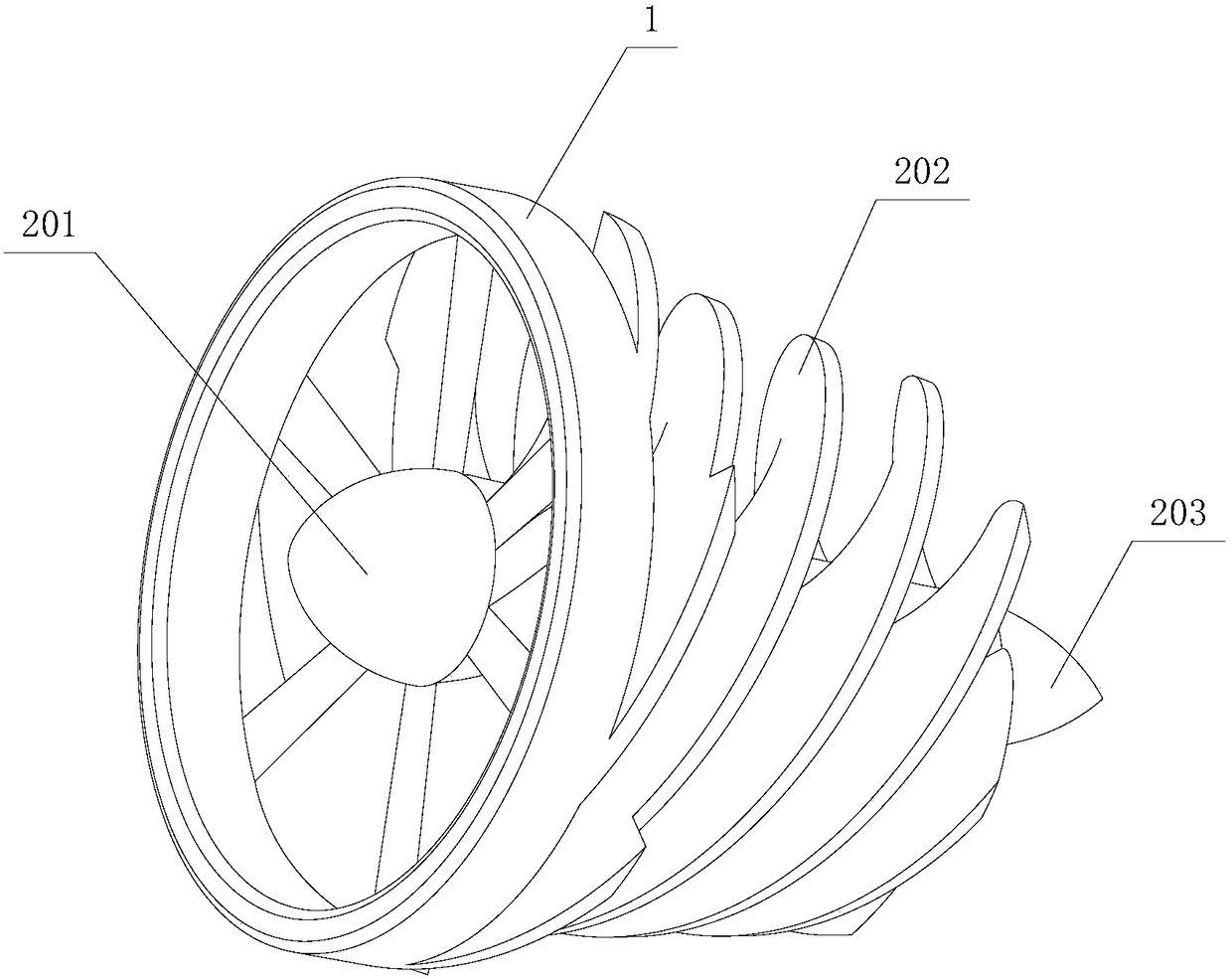

[0031] The spinner of the low-pressure-loss type precession vortex flowmeter of the present invention has a conical structure as a whole, and the middle section of the spinner hub is a conical structure, and there is a taper from front to back, which can make the transition of the fluid flow channel strong. , the pressure loss is reduced; secondly, the vortex strength of the gas entering the flowmeter can be enhanced, which can effectively reduce the measurement lower limit of the flowmeter and widen the flow range; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Helix angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com