Jet flow meter using vertical drain flow path and double outlet structure

A double-outlet, flowmeter technology, applied in the direction of volume/mass flow generated by detecting the dynamic effect and mechanical effect of fluid flow, etc., can solve problems such as limiting the range of flowmeter, weak pressure signal strength, and affecting measurement accuracy , to achieve the effect of reducing the lower limit of measurement, reducing interference and improving anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

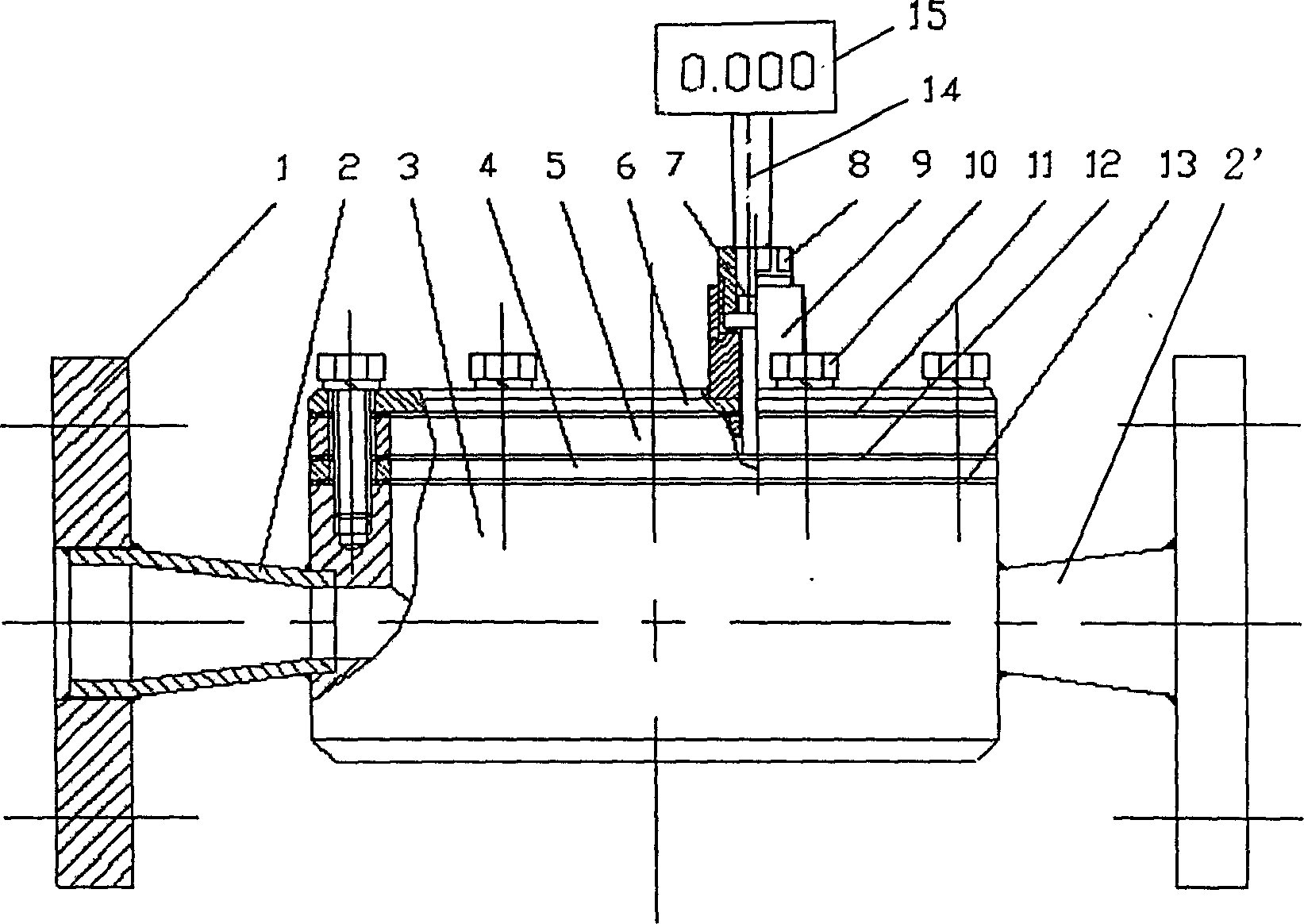

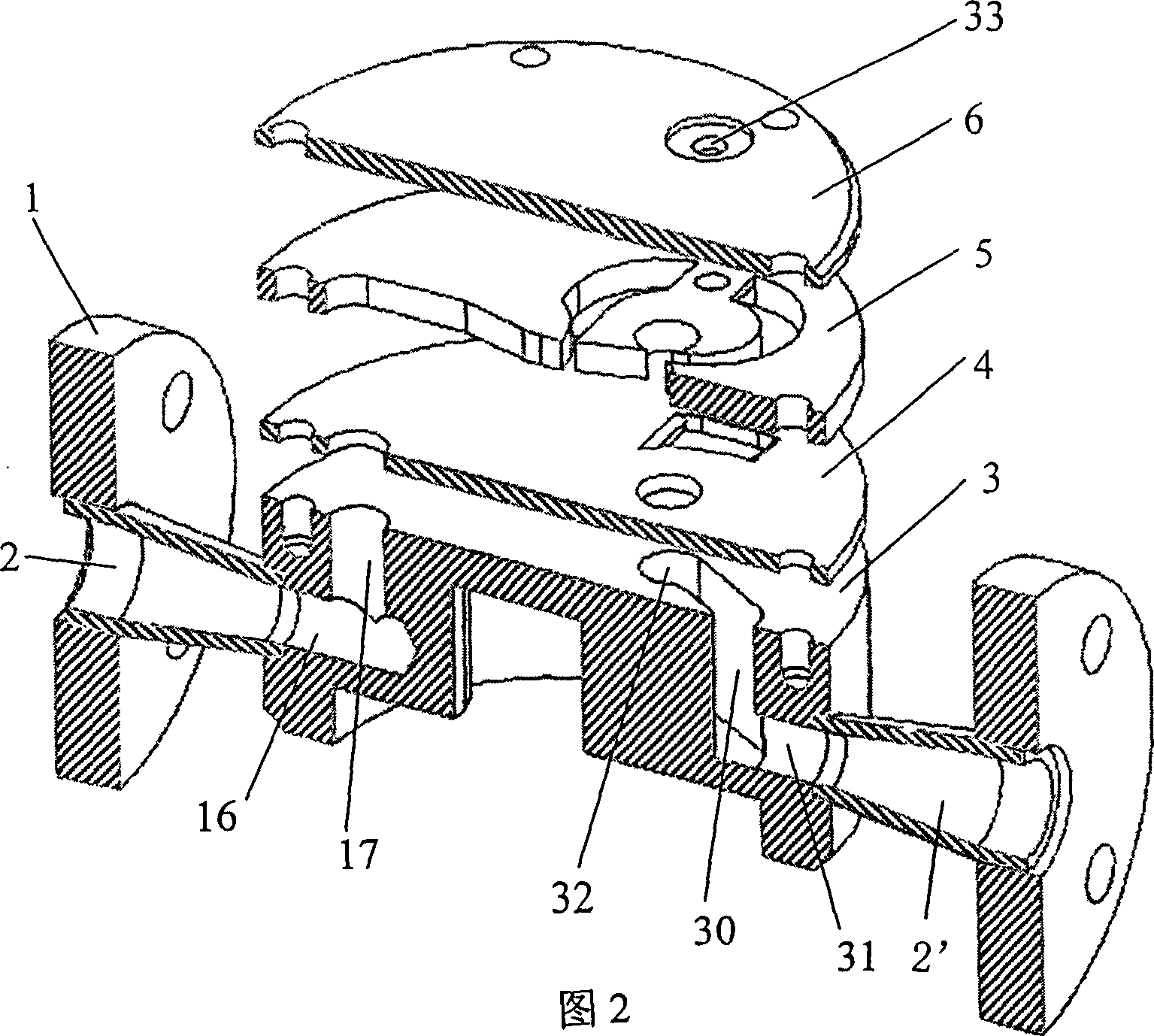

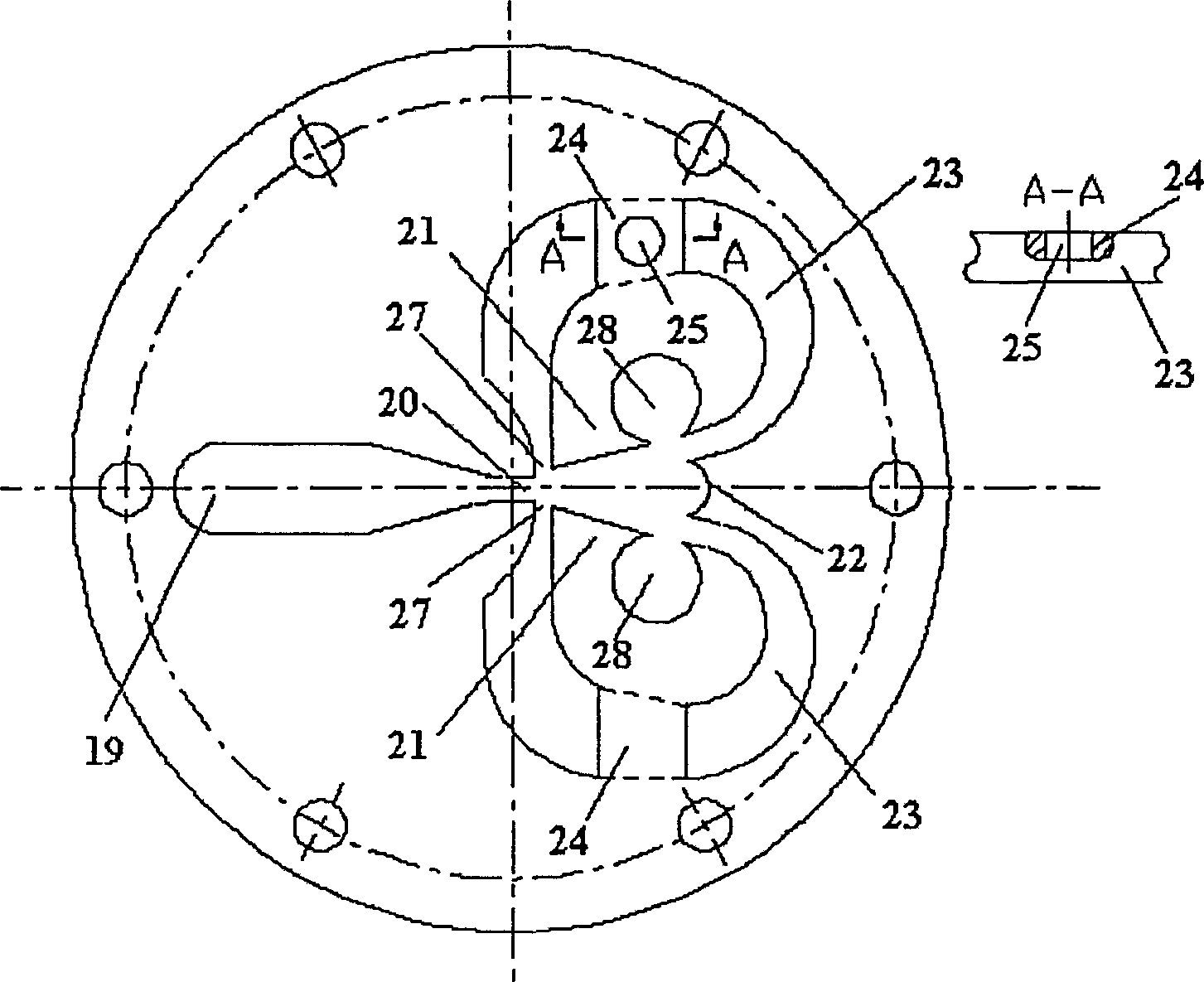

[0018] Such as figure 1 ,figure 2, image 3 and Figure 4 As shown, the present invention provides a jet flowmeter adopting a vertical drainage channel and a double outlet structure, which includes:

[0019] 1) Flange 1, shrinkage tube 2, expansion tube 2', body 3, partition 4, jet part 5, end cover 6, sensor 7, screw 8, boss 9, secondary instrument 15; body 3 is at the entrance It is welded with the shrink tube 2 with flange 1, and the outlet is welded with the expansion tube 2' with another flange 1; the partition 4 and the jet element 5 are horizontally stacked on the upper plane of the body 3 from bottom to top, Above the jet element 5, there is an end cover 6 to fix the partition plate 4 and the jet element 5 on the body 3 through screws 10; 14 is connected with the secondary instrument 15 outside the body 3;

[0020] 2) Inside the body 3, the inlet is compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com