Finite element analysis simplified method of turnover protection structure

A protective structure, finite element technology, applied in the field of finite element analysis simplification of rollover protective structure, can solve the problems of simulation analysis losing the reference value of bolt connection performance evaluation, difficult convergence, cumbersome operation, etc., and achieve fast and accurate bolt connection analysis , Reduce the difficulty of analysis convergence and save analysis resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

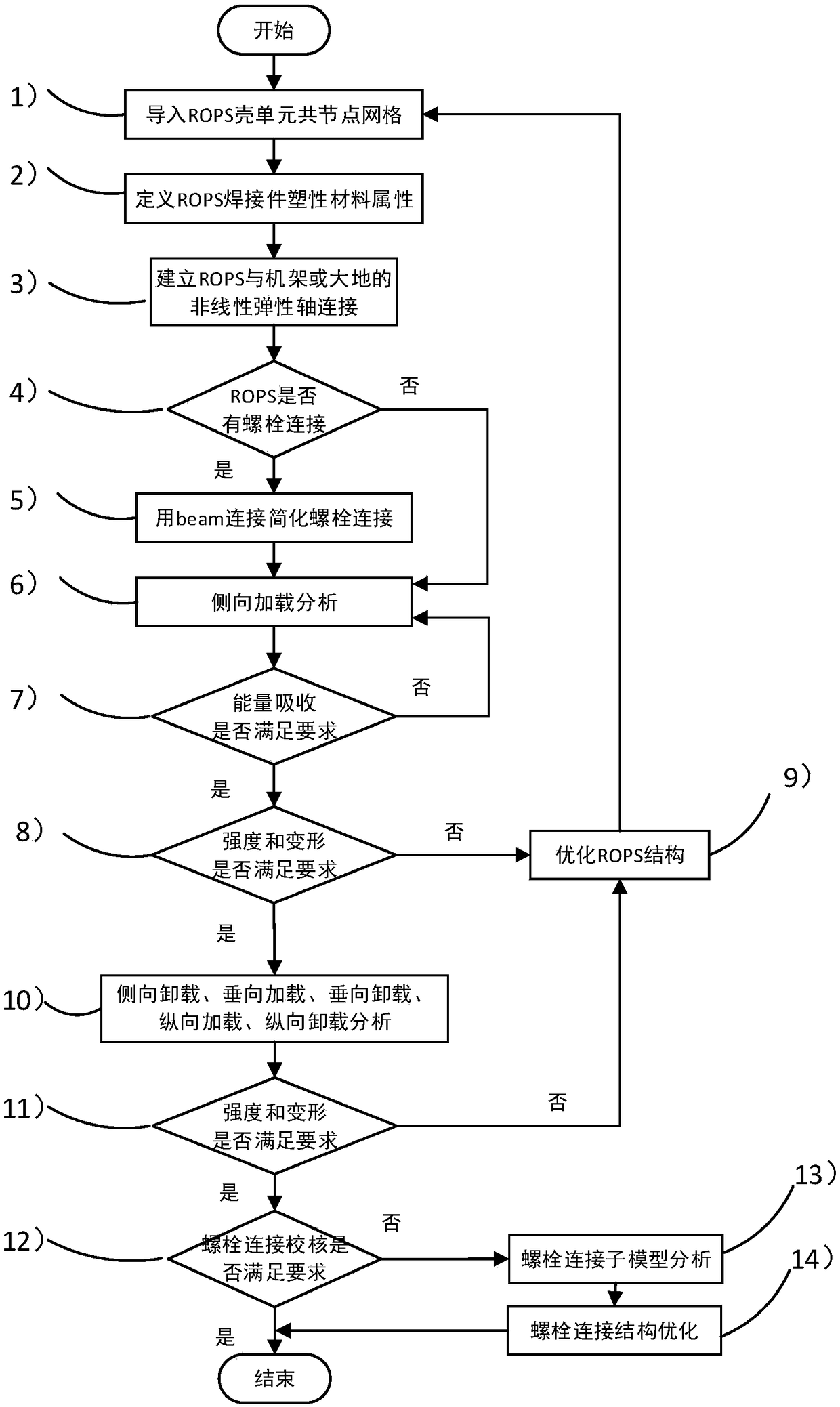

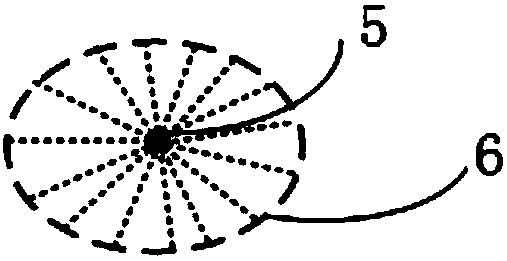

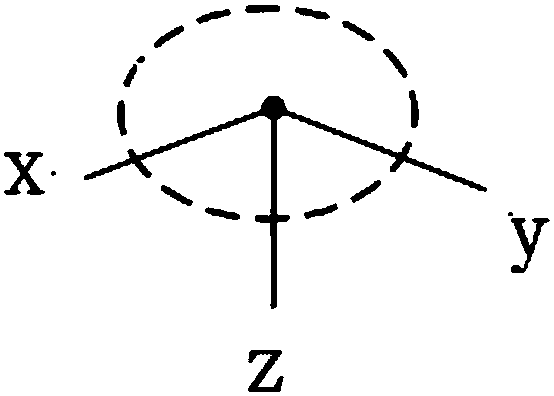

[0069] The present invention utilizes the nonlinear elastic axis connections in the three directions of x, y, and z to replace the definition of complicated materials and contact properties of elastic vibration absorbers for rollover protective structures (ROPS); use beam (beam) connection and bolt connection sub-model analysis According to the national standard GB / T 17922-1999, optimize the establishment of the rollover protective structure (ROPS) analysis load combination sequence.

[0070] Below, take a certain type of rollover protective structure (ROPS) as an example, utilize the method of the present invention to carry out the finite element analysis of the rollover protective s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com