A Reliable Method for Verifying the Fragmentation Distribution of Exploded Heap

A technology of degree distribution and stacking, applied in image analysis, image enhancement, instruments, etc., can solve problems such as poor image clarity, and achieve the effects of fast statistical speed, high resolution, and adjustable resolution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

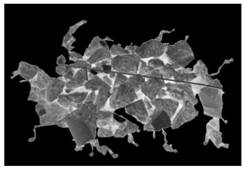

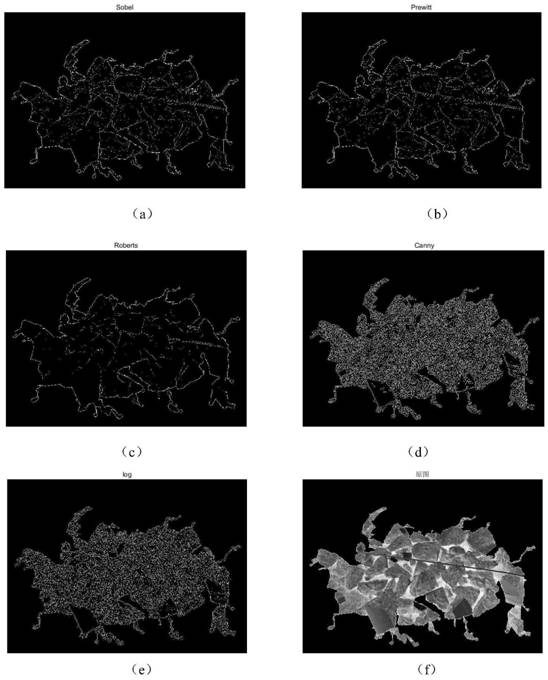

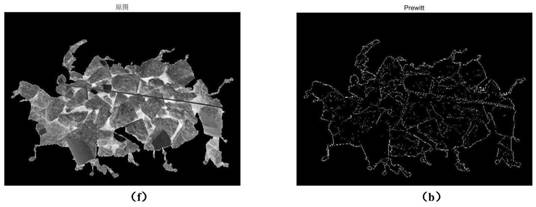

[0065] 1) The format of the image to be processed is: 9,447,670 bytes captured by a 13-megapixel camera, the size is 4608×3456px, and the on-site burst photos with a scale of millimeter graduation values.

[0066] 2) Due to the high pixel of the image and the horizontal scale reference, AuToCAD 2014 or above is selected as the preliminary processing software. Set the [Graphic Unit] dialog box in the CAD software with reference to the scale length and division value, select "Decimal" for "Length", select "Decimal Degrees" for "Angle Type", and select "Millimeter" for the scaling unit when inserting. In the CAD orthogonal mode, draw a horizontal scale line with the same length and unit as the picture scale, and convert the high-definition original figure 1 : 1 Import directly above the horizontal scale line. If the width of the shooting burst exceeds two meters, import by area according to different area scales (realized by cropping pictures or freezing layers). The unit precis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com