Automatic molding device for deep-fried dough sticks

An automatic forming and deep-fried dough stick technology, which is applied in dough forming and cutting equipment, dough extruder, etc., can solve the problems of high maintenance cost, difficulty in popularization and application, complex structure, etc., achieve natural and refreshing taste, and reduce cooking and frying Time, to avoid the effect of bad taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

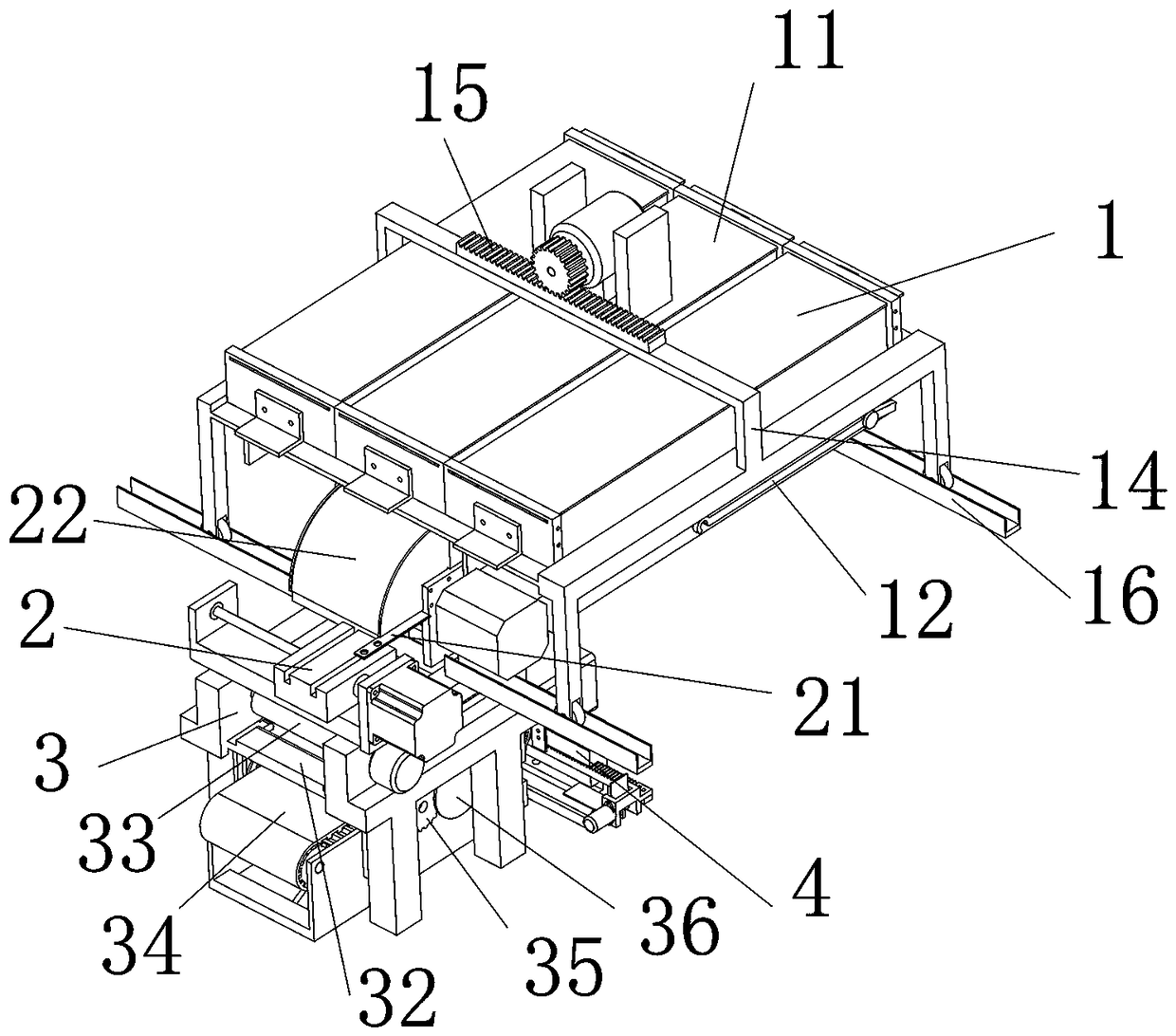

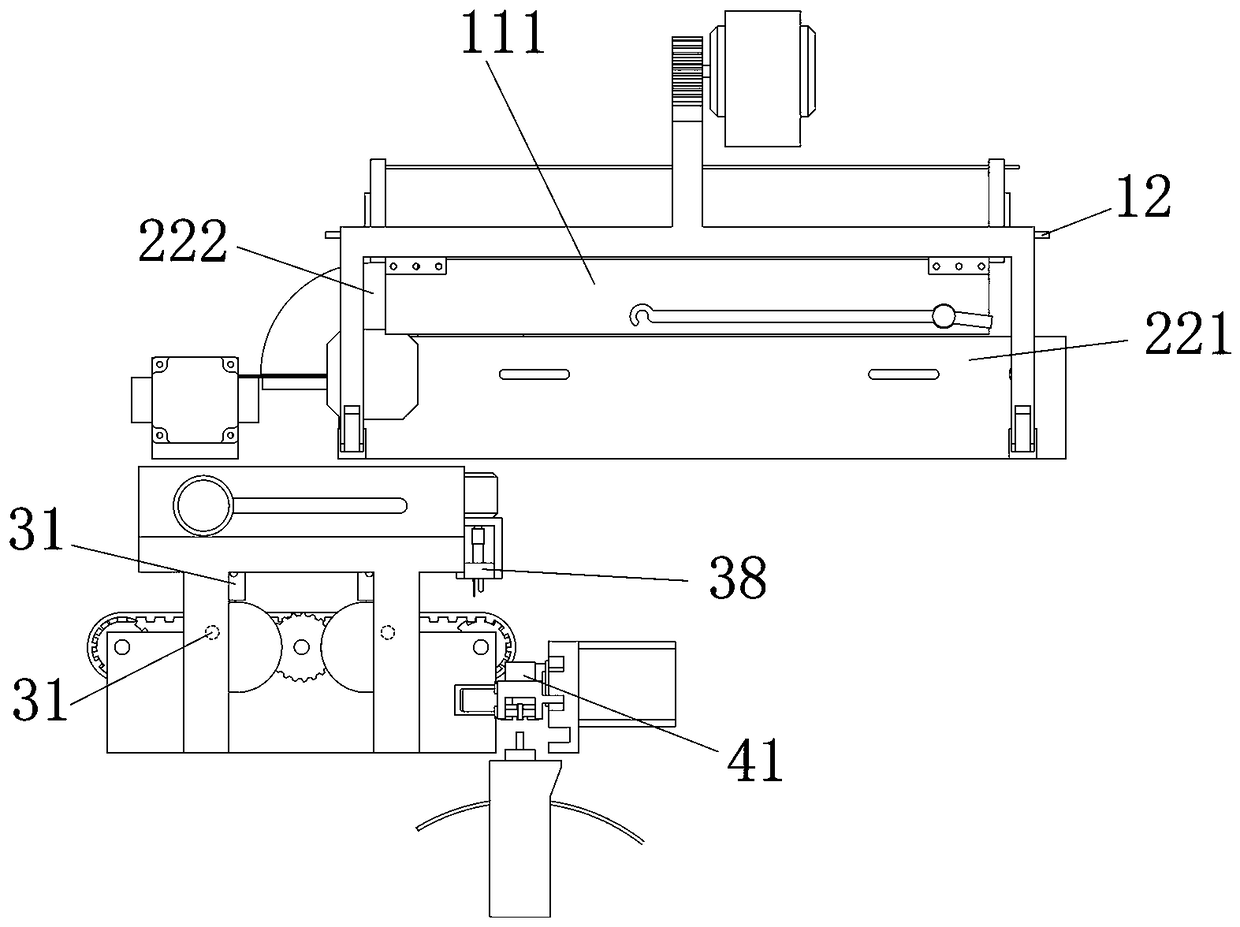

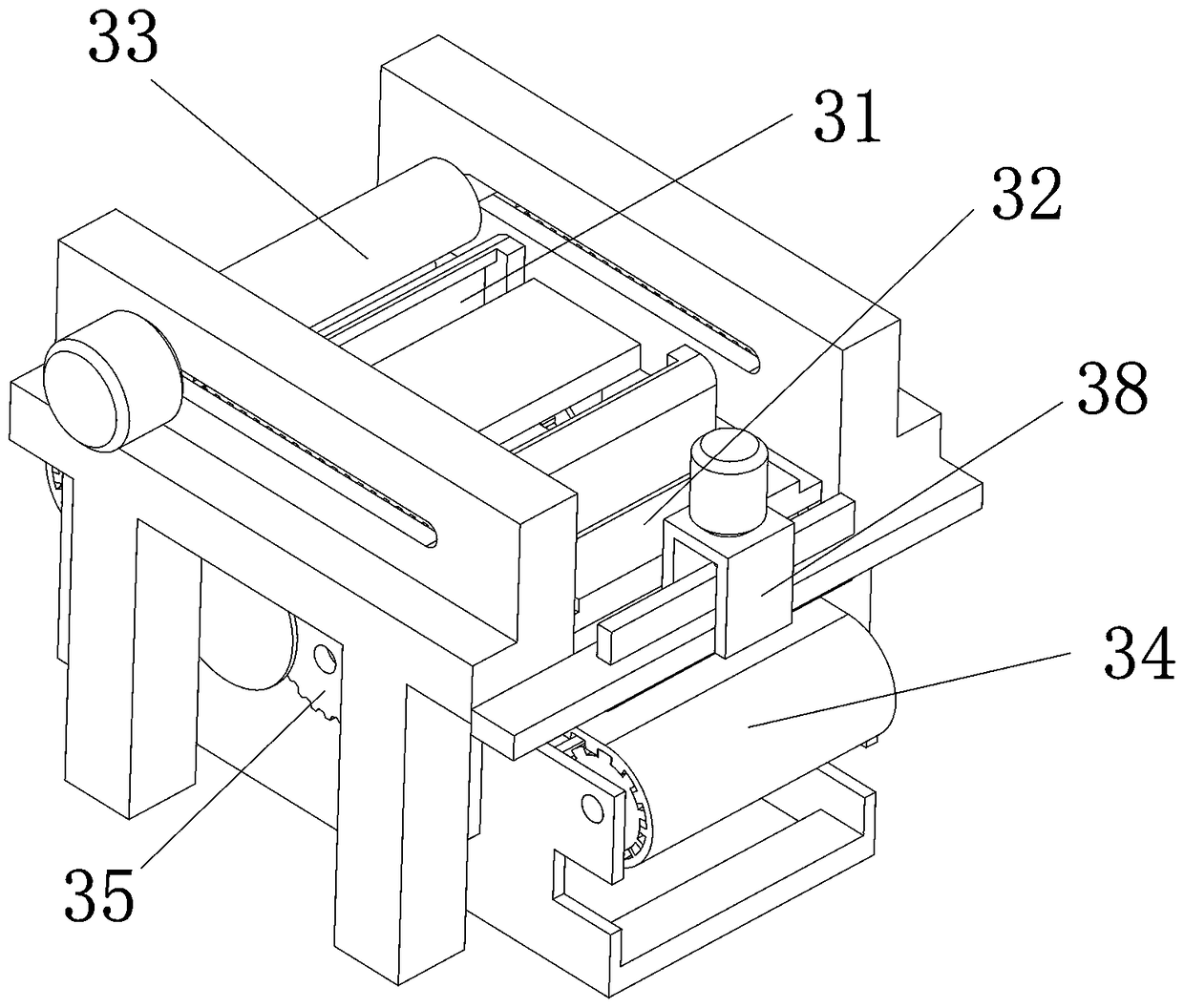

[0034] Such as figure 1 , 2, 3, 4 and 5, an automatic forming device for deep-fried dough sticks is characterized in that: it includes a storage and blanking device 1, a rough cutting device 2, an extrusion re-cutting device 3 and a stretching forming device 4 that are sequentially connected; The storage and blanking device 1 includes a plurality of storage hoppers 11, lockers 12, and a lock switch 13 for controlling the lockers 12. The storage hopper 11 has only one upper opening, and the bottom surface is a loose-leaf structure. The locking device 12 is used to lock the loose-leaf structure of the bottom surface of the storage hopper 11. When the automatic forming operation of fried dough sticks is required, the dough embryos that have been sent are put into a plurality of the storage hoppers 11, and through the lock The stop switch 13 controls the locker...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap