A treatment device for high temperature waste gas

A high-temperature exhaust gas and treatment device technology, which is applied in the direction of steam engine equipment, separation methods, filtration and separation, etc., can solve the problems of waste heat of exhaust gas not being used reasonably, low purification rate of exhaust gas, waste of resources, etc., to achieve convenient cleaning and saving Effect of water use and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

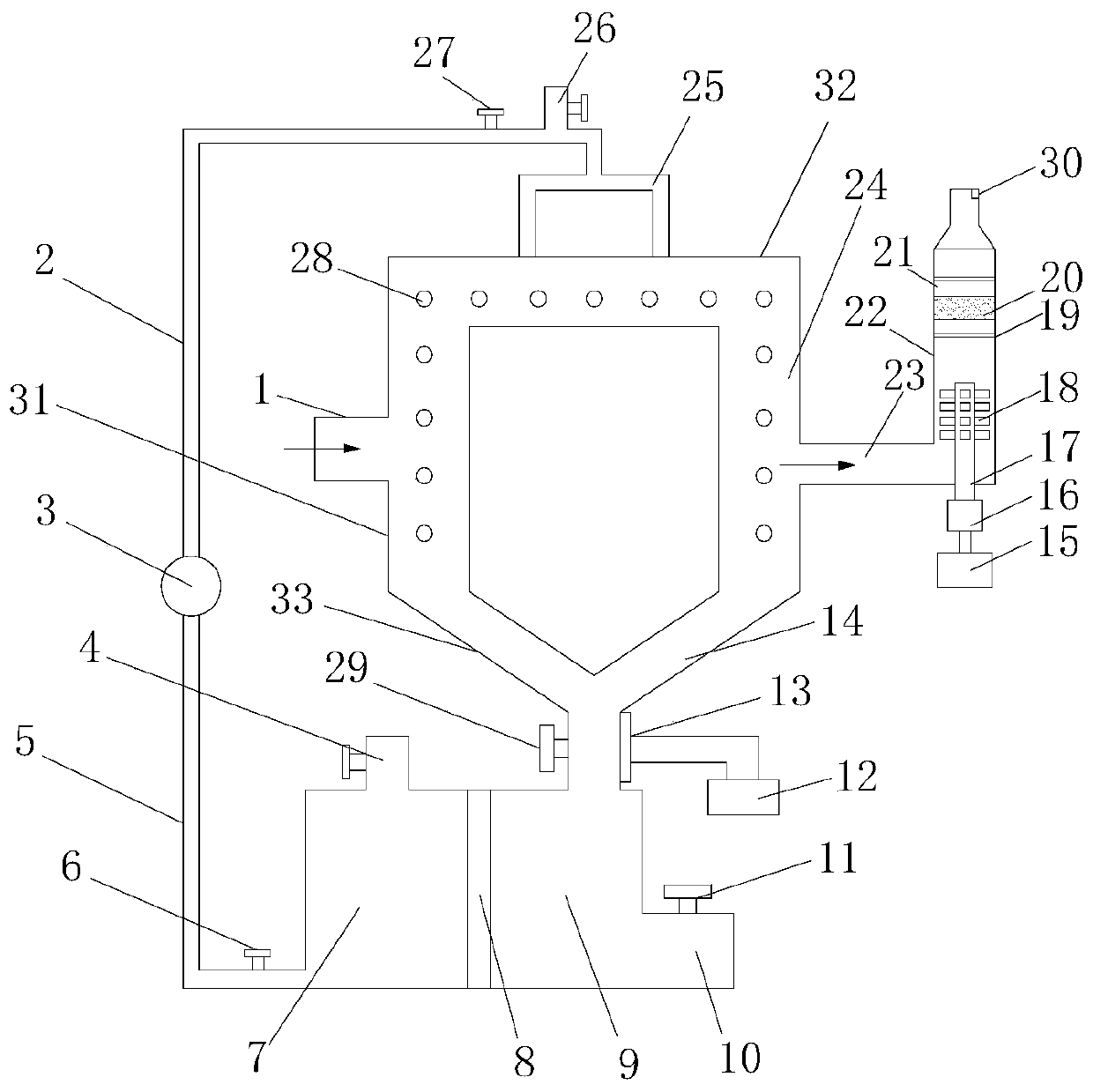

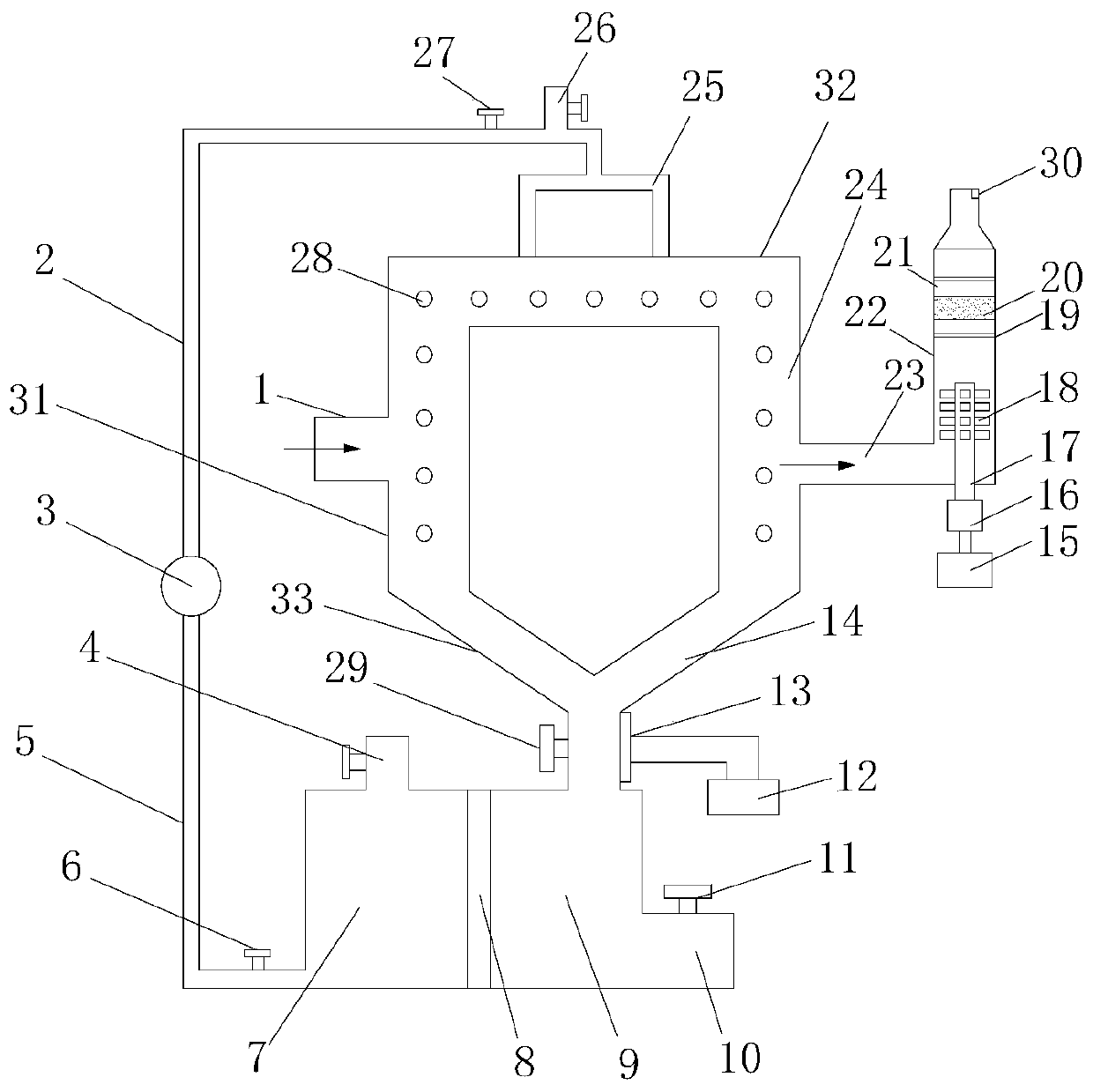

[0034] Embodiment 1: the purification unit comprises barbed wire 19, and its quantity is two, and is horizontally arranged in the purification pipe 22; Oil-absorbing cotton 21, its quantity is two, and is arranged between two barbed wire 19; Activated carbon 20, it is filled in two Between 21 pieces of oil-absorbing cotton.

Embodiment 2

[0035] Embodiment 2: The purification unit includes two purification nets loaded with catalysts, which are horizontally arranged in the purification pipeline 22, and the catalysts are nano-scale titanium dioxide, zinc oxide, niobium pentoxide, tungsten trioxide, tin dioxide, trioxide One or more of diiron and zinc sulfide; an ultraviolet irradiator is also provided in the purification pipeline 22, and the ultraviolet irradiator irradiates toward the purification net, and the purification net 19 is made of multi-layer 0.03mm metal.

[0036] The gas outlet is provided with a detection unit for detecting gas components, and the detection unit includes a gas sensor 30, which is one or more of a carbon monoxide sensor, a sulfur dioxide sensor, a nitrogen monoxide sensor and a hydrogen sulfide sensor; 30 connections for displaying test data.

[0037]The power generation assembly includes an impeller 18, a rotating shaft 17, a generator 16 and a first storage battery 15. Several impe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com