Leaf crushing and recycling equipment for landscape maintenance

A technology of reuse and leaves, applied in lighting and heating equipment, dryers, grain processing and other directions, can solve the problems of screening out, increasing costs, affecting the reuse of leaves, etc., to improve the crushing effect and facilitate packaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

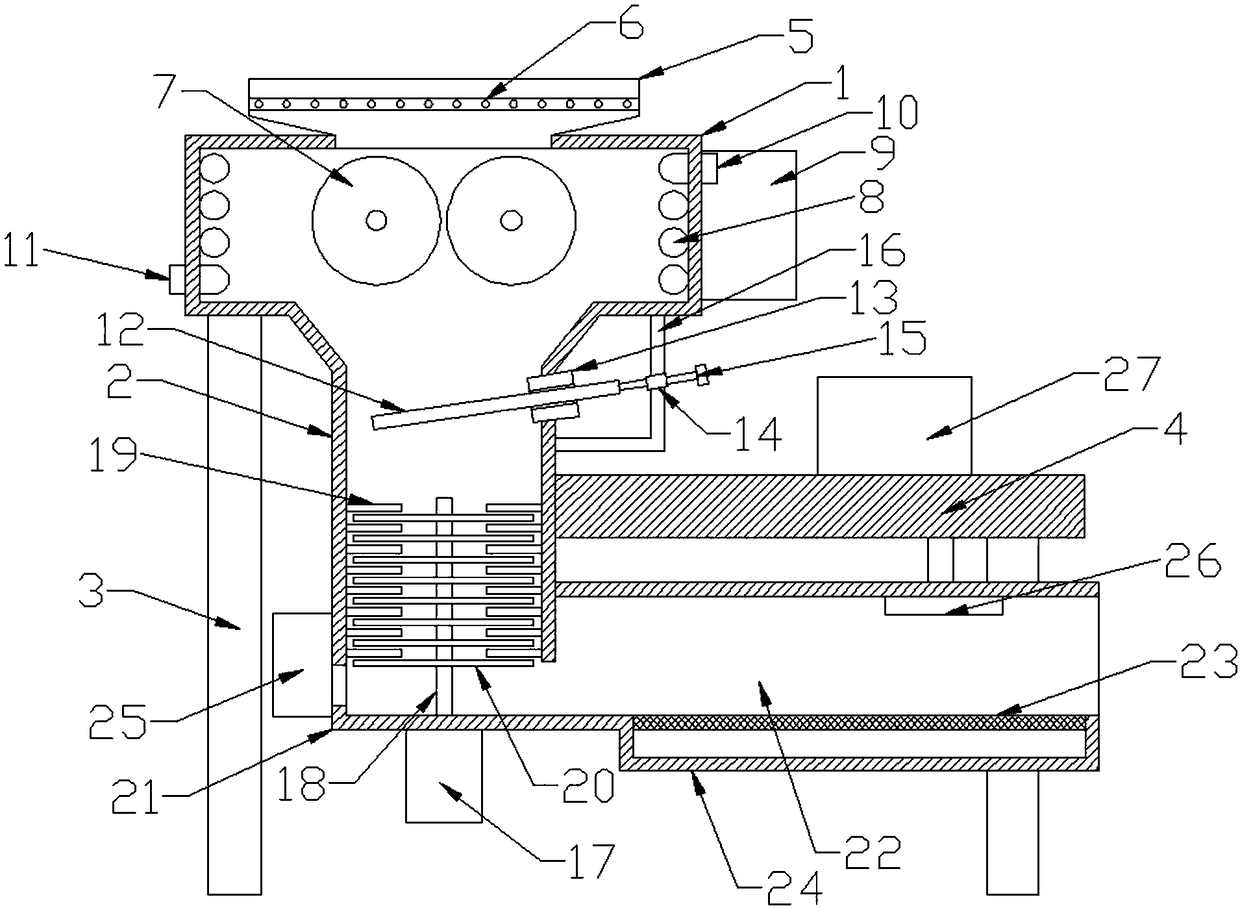

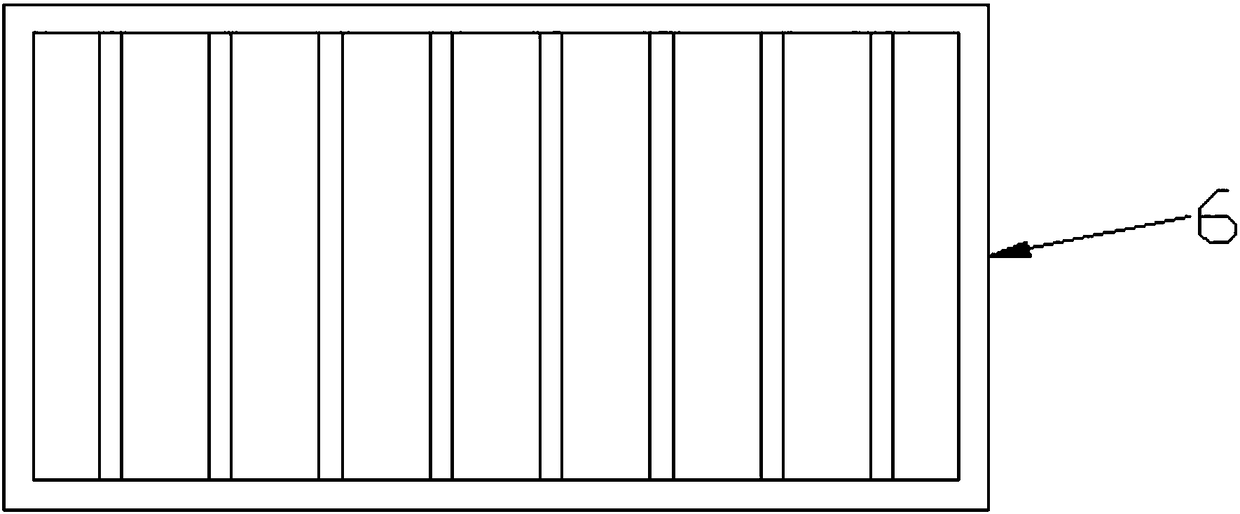

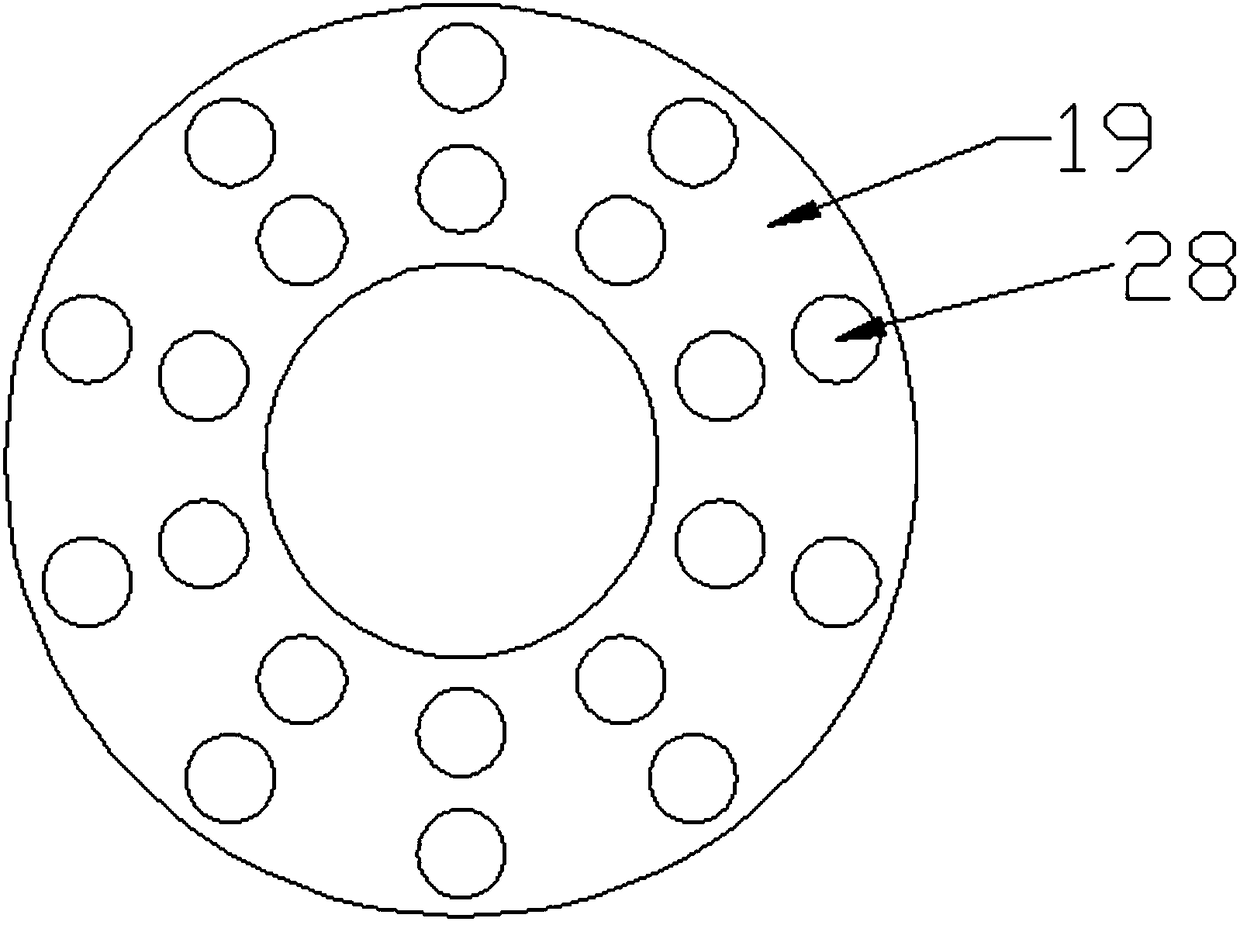

[0017] Referring to the figure, in the embodiment of the present invention, a leaf crushing and recycling equipment for garden maintenance includes a pre-crushing box 1, a crushing drum 2, a leg 3, a support 4, a hopper 5, and a crushing motor 17; The crushing box 1 is connected to the top of the crushing drum 2, and a horizontal discharge box 21 is connected to the lower end of the crushing drum 2. The legs 3 are fixedly welded to the pre-crushing box 1, and the bracket 4 is fixedly welded to the crushing cylinder 2. The legs 3 and the bracket 4 support the equipment; the feed hopper 5 is connected to the top of the pre-crushing box 1, and a horizontal screen 6 is fixedly installed in the feed hopper 5, and the screen 6 is evenly distributed by the outer frame and the frame The distance between adjacent barriers is small, so that leaves can pass through the sieve plate 6, and some larger objects, such as branches, cannot pass through, so that only leaves enter the equipment; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com