Computer numerical control bending machine

A bending machine and frame technology, applied in the field of steel bar bending hoop devices, can solve the problems of limited diameter range of compressed steel bars, encoders easily damaged by vibration, and steel bars are not easy to adjust, etc., and achieves good straightening effect and low vibration. , The effect of not easily damaged by vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

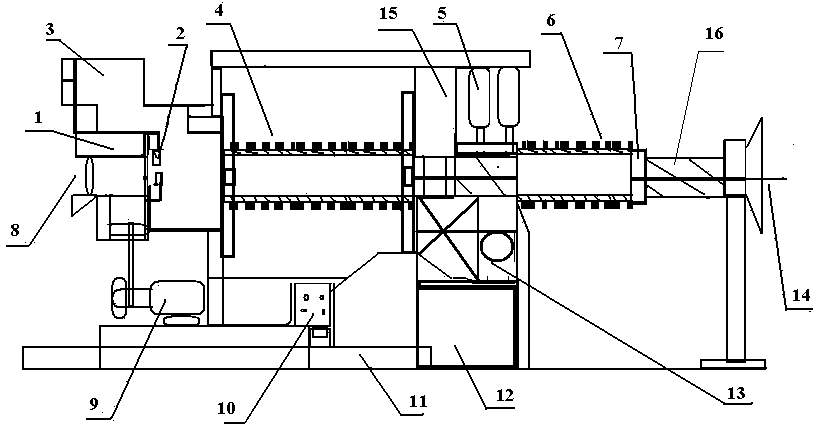

[0018] The following will be further described in conjunction with the accompanying drawings, not to limit the scope of the present invention.

[0019] see figure 1 As shown, the present invention comprises frame 11 and cutting mechanism 1, and a cutting motor 9 is installed on the bottom of frame 11, and described cutting motor 9 provides power for cutting mechanism 1, and the main shaft of described cutting motor 9 passes through a transmission mechanism It is connected with the cutting mechanism 1. A bending hoop mechanism 3 is installed on one side of the cutting mechanism 1, and a split blade 2 is arranged inside the bending hoop mechanism 3. Anaerobic glue is added to the split blade 2 to organically combine the blade and the knife body, eliminating the need for blades Disadvantages of serial movement relative to the cutter body, cost saving, and easy disassembly and assembly. The bending hoop mechanism 3 generally has several bending actions for each hoop. The input sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com