Pneumatic tire with dual bead fillers

A technology of pneumatic tires and apex rubber, which is applied to tire parts, tire edges, transportation and packaging, etc., can solve the problem that the position of cord and apex is easy to separate, the boundary position of cord and wear-resistant rubber is separated, and the difference of stress and strain is large. and other problems to achieve the effect of reducing the risk of separation, without sacrificing the rigidity of the sidewall, and balancing the stress and strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

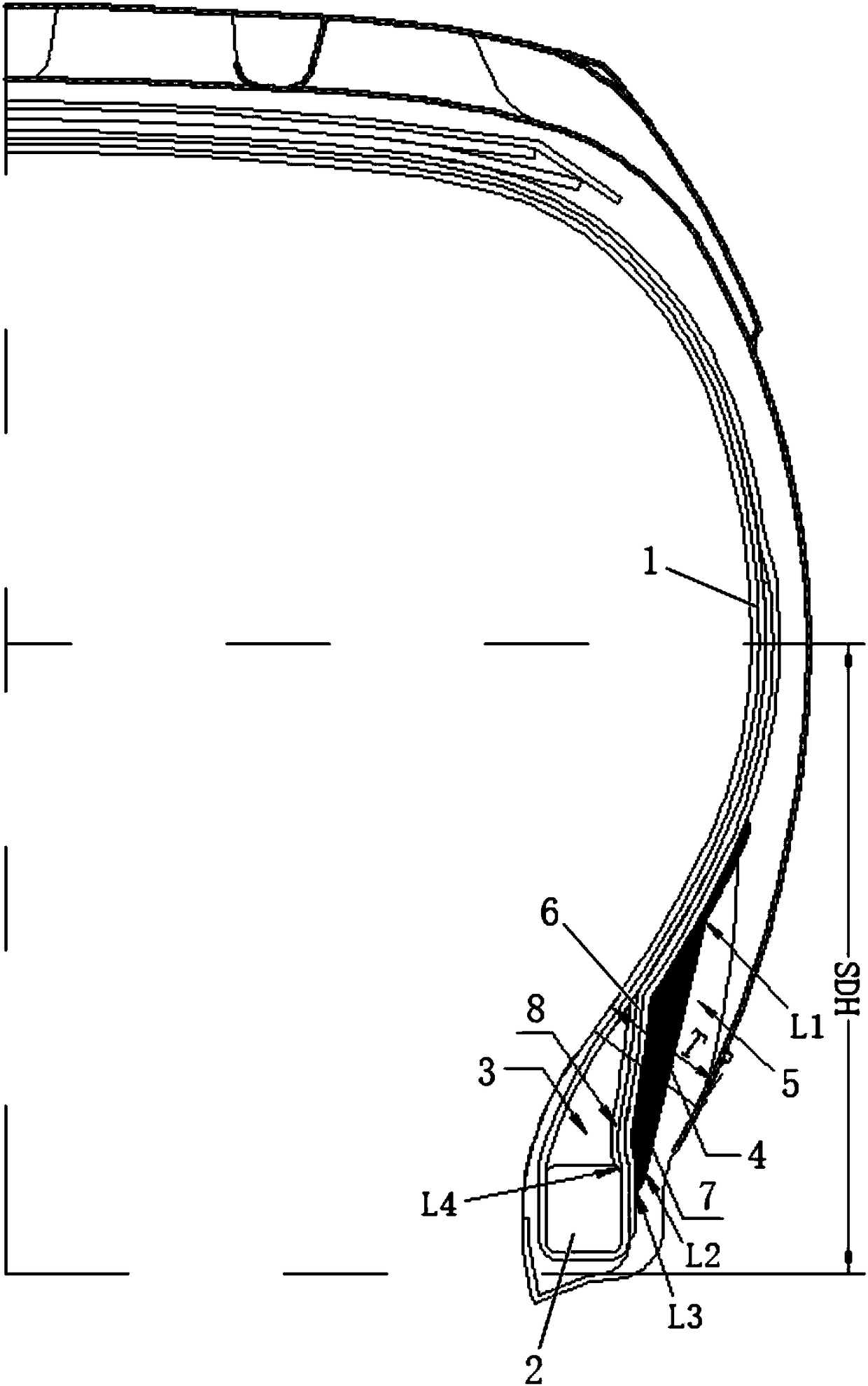

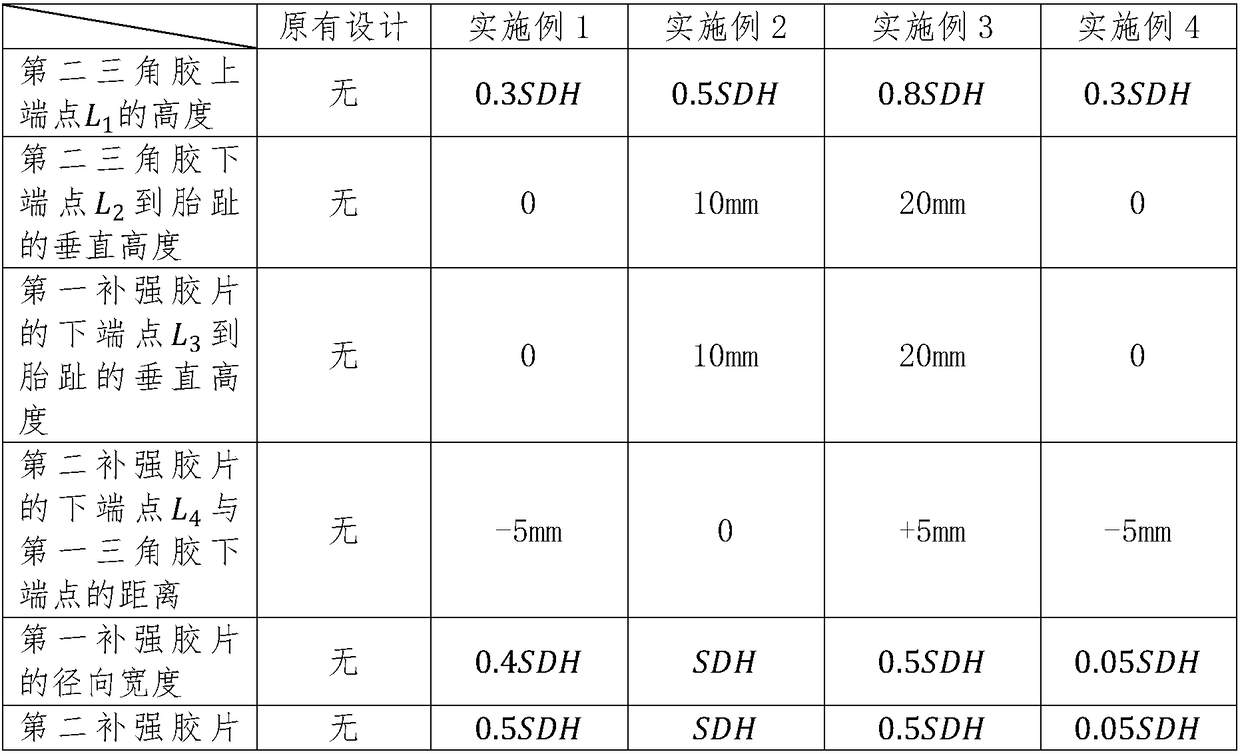

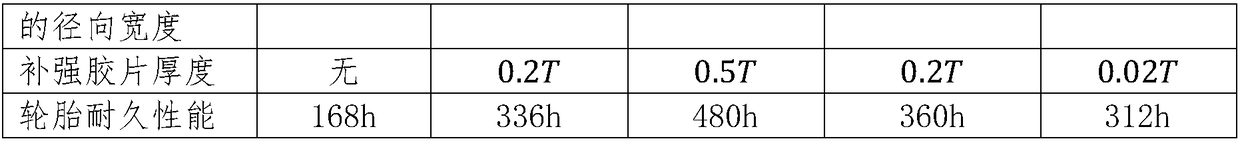

[0030] End point L on the second apex 1 The height is 0.3SDH, the lower endpoint of the second apex L 2 Located at the fetal toe, where SDH is the vertical height from the widest point of the sidewall to the fetal toe.

[0031] The lower end point L of the first reinforcing film 3 Also located at the fetal toe, the lower end point L of the second reinforcing film 4 Located 5mm below the lower end of the first apex.

[0032] The radial width of the first reinforcing film is 0.4SDH, the radial width of the second reinforcing film is 0.5SDH, and the thickness is 0.2T, where SDH is the vertical height from the widest part of the sidewall to the tire toe, and T is the rim line total thickness.

Embodiment 2

[0034] End point L on the second apex 1 The height is 0.5SDH, the lower endpoint of the second apex L 2 The vertical height to the fetal toe is 10mm, where SDH is the vertical height from the widest point of the sidewall to the fetal toe.

[0035] The lower end point L of the first reinforcing film 3 The vertical height to the fetal toe is 10mm, the lower end point L of the second reinforcing film 4 Located at the lower end of the first apex.

[0036] Both the radial width of the first reinforcing film and the second reinforcing film are SDH, and the thickness is 0.5T, wherein SDH is the vertical height from the widest part of the sidewall to the tire toe, and T is the total thickness at the rim line.

Embodiment 3

[0038] End point L on the second apex 1 The height is 0.8SDH, the lower endpoint of the second apex is L 2 The vertical height to the fetal toe is 20mm, where SDH is the vertical height from the widest point of the sidewall to the fetal toe.

[0039] The lower end point L of the first reinforcing film 3 The vertical height to the fetal toe is 20mm, the lower end point L of the second reinforcing film 4 Located 5mm above the lower end of the first apex.

[0040] The radial width of the first reinforcing film is 0.5SDH, the radial width of the second reinforcing film is 0.5SDH, and the thickness is 0.2T, where SDH is the vertical height from the widest part of the sidewall to the tire toe, and T is the rim line total thickness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com