Heat preservation board, production method thereof and cold chain heat preservation storage box

A technology of thermal insulation board and thermal insulation box, applied in the field of thermal insulation materials, can solve the problems of decreased thermal insulation performance, thermal insulation performance and sealing performance of thermal insulation boxes, and inability to give full play to the thermal insulation performance of vacuum thermal insulation boards, etc. high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

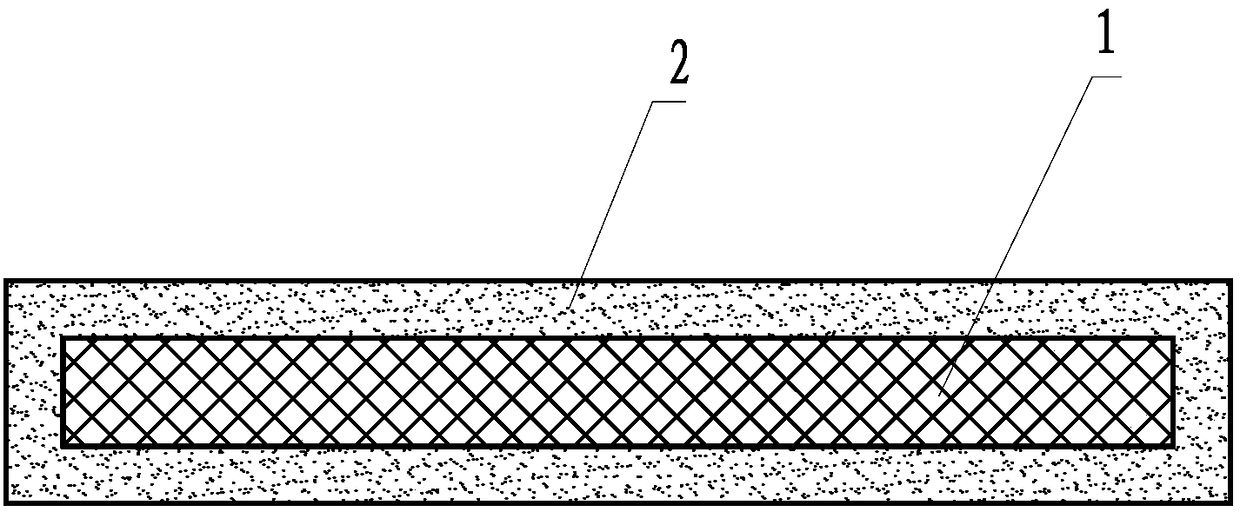

[0026] refer to figure 1 , a thermal insulation board 1, comprising: a vacuum insulation board 1 and a high-resilience polyurethane foam 2 covering it; the high-resilience polyurethane foam 2 is coated on the upper and lower surfaces of the vacuum insulation board 1, and The surrounding sides of the heat insulation board 1; the density of the high resilience polyurethane foam 2 is ≥30kg / m 3 ;

[0027] The coating thickness of the high-resilience polyurethane foam 2 on the upper and lower surfaces of the vacuum insulation panel is ≤20 mm, and the coating thickness of the surrounding sides is ≤10 mm.

[0028] Because the high-resilience polyurethane foam 2 has the characteristics that it can undergo certain deformation when subjected to external force load, and quickly restores its original shape and size after losing the external force load. Therefore, it can provide the vacuum insulation panel 1 with sufficient anti-vibration, cushioning and compression resistance, effective...

Embodiment 2

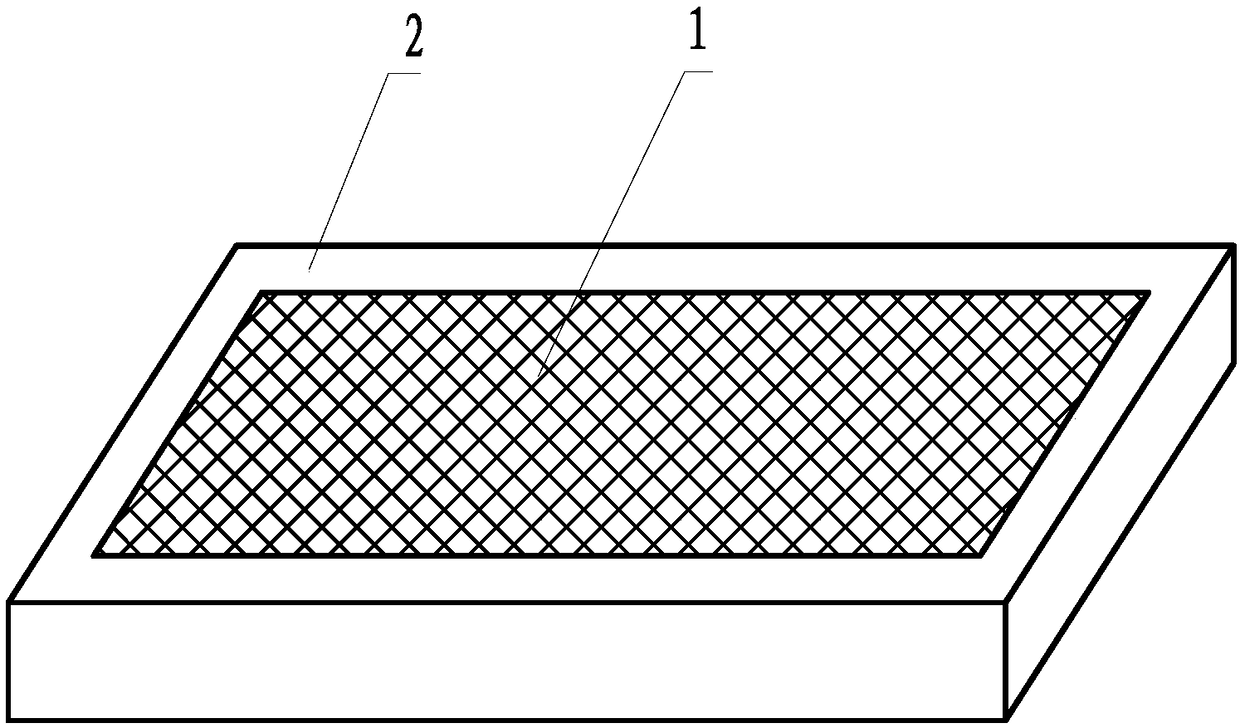

[0038] The difference between this embodiment and Embodiment 1 is that: the side of the insulation board 1 close to the inner wall of the outer box is not coated with the high resilience polyurethane foam 2; the side farther away from the inner wall of the outer box is covered with the high resilience polyurethane foam 2 . like Figure 3-4 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap