Automatic paving and stacking method

A stacking and automatic technology, applied in the field of electromechanical automation, automatic paving and stacking, to achieve the effect of low operating cost, good quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

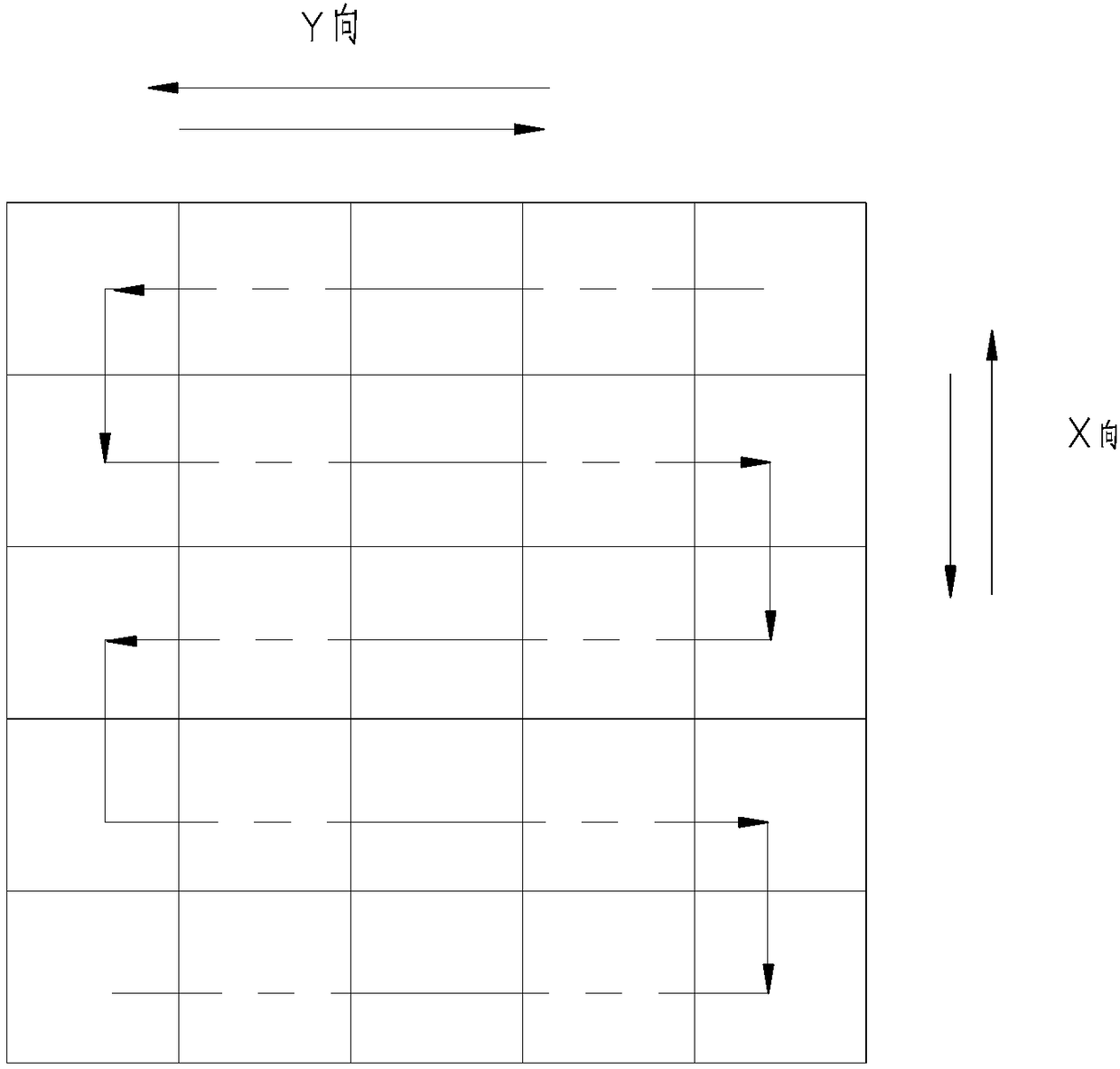

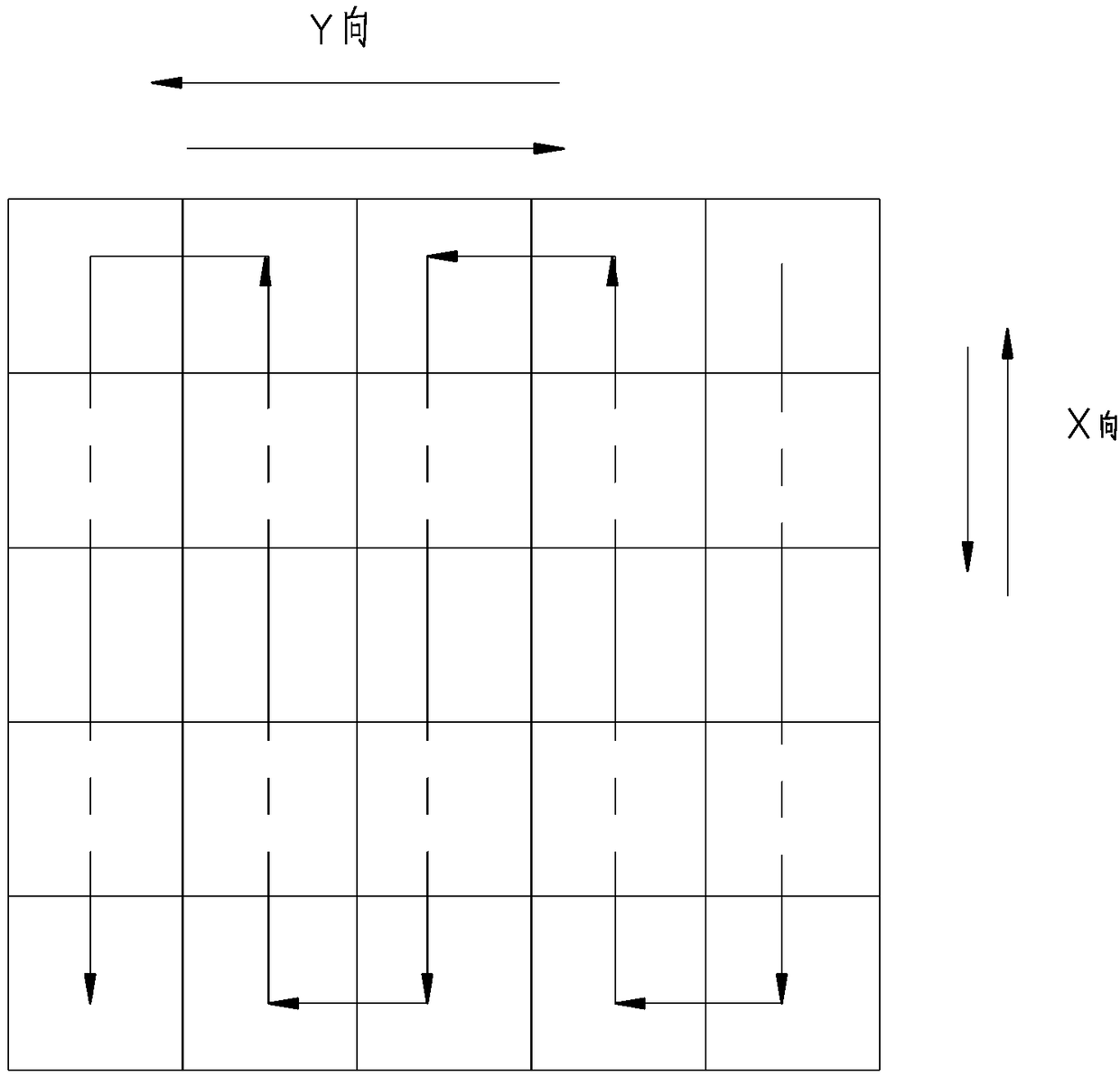

[0025] Such as figure 1 As shown, an automatic paving and palletizing method is realized by an automatic paving and palletizing equipment, and the automatic paving and palletizing equipment has a paving and palletizing conveyor and a feeding material closely matched with the paving and palletizing conveyor Conveyor, the feeding conveyor is used to continuously supply the packages to the paving and palletizing conveyor, and the paving and palletizing conveyor is used to drive the packages to move forward or backward in the paving direction of one paving , the paving and palletizing conveyor is also used to be driven to move along the stacking direction X, Y and Z to realize stacking in the length, width and height directions (geometric cubes) of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap