High-altitude anti-inclination steel frame structure and installation method thereof

An installation method and steel frame technology, applied in the direction of building structure, construction, etc., can solve the problems of lack of stability and wind resistance, poor resistance to external force, poor resistance to external force, etc., to achieve enhanced stability and wind resistance , Strong wind and earthquake resistance, and the effect of improving the ability to resist external forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

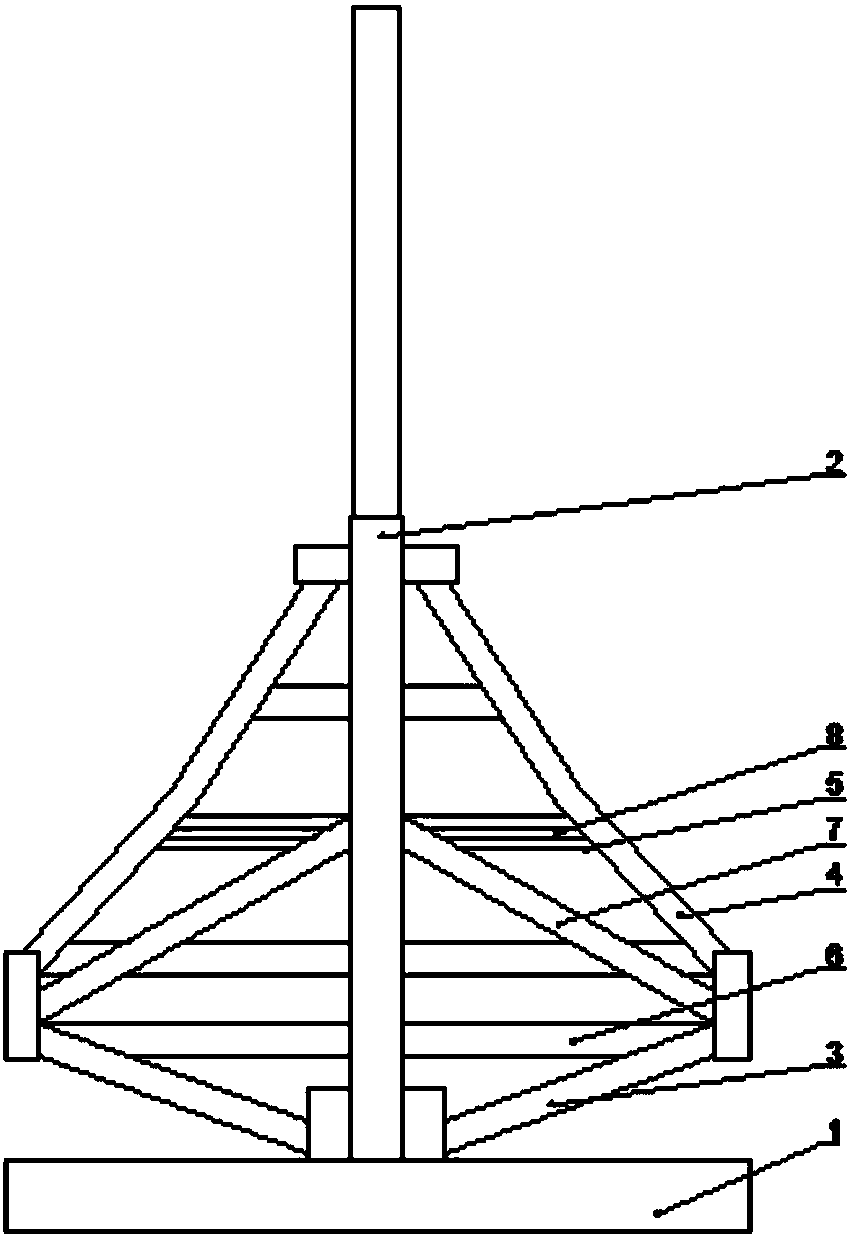

[0038] Such as figure 1 A high-altitude anti-tilt steel frame structure shown includes: a supporting beam 1, a mast 2, a supporting rod 3, a supporting oblique rod 4 and a hoop rod 5, the supporting beam 1 is provided with a mast 2, and the mast 2 The lower end is connected with a supporting rod 3, the middle section of the mast 2 is provided with a supporting diagonal rod 4, and the supporting diagonal rod 4 is provided with a circumferential rod 5; one end of the supporting rod 3 is connected to one end of the supporting diagonal rod 4 The ends are connected.

[0039] The mast 2 described in this embodiment includes an upper mast and a lower mast, and the upper mast and the lower mast are connected and fixed by bolts and nuts, and the supporting rod 3 and the supporting slanting rod 4 are both arranged on the lower mast.

[0040] The support beam 1 described in this embodiment is welded with a limit clamp, and a mast 2 is arranged inside the limit clamp, and the limit clamp...

Embodiment 2

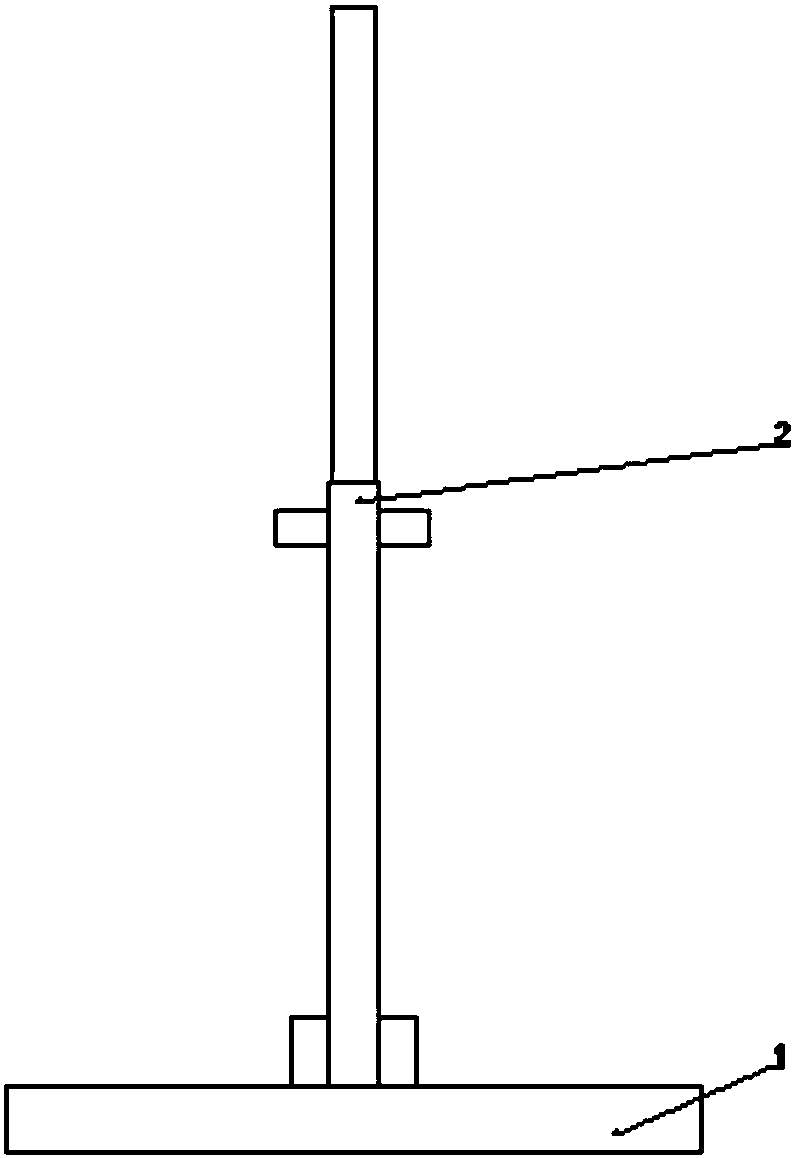

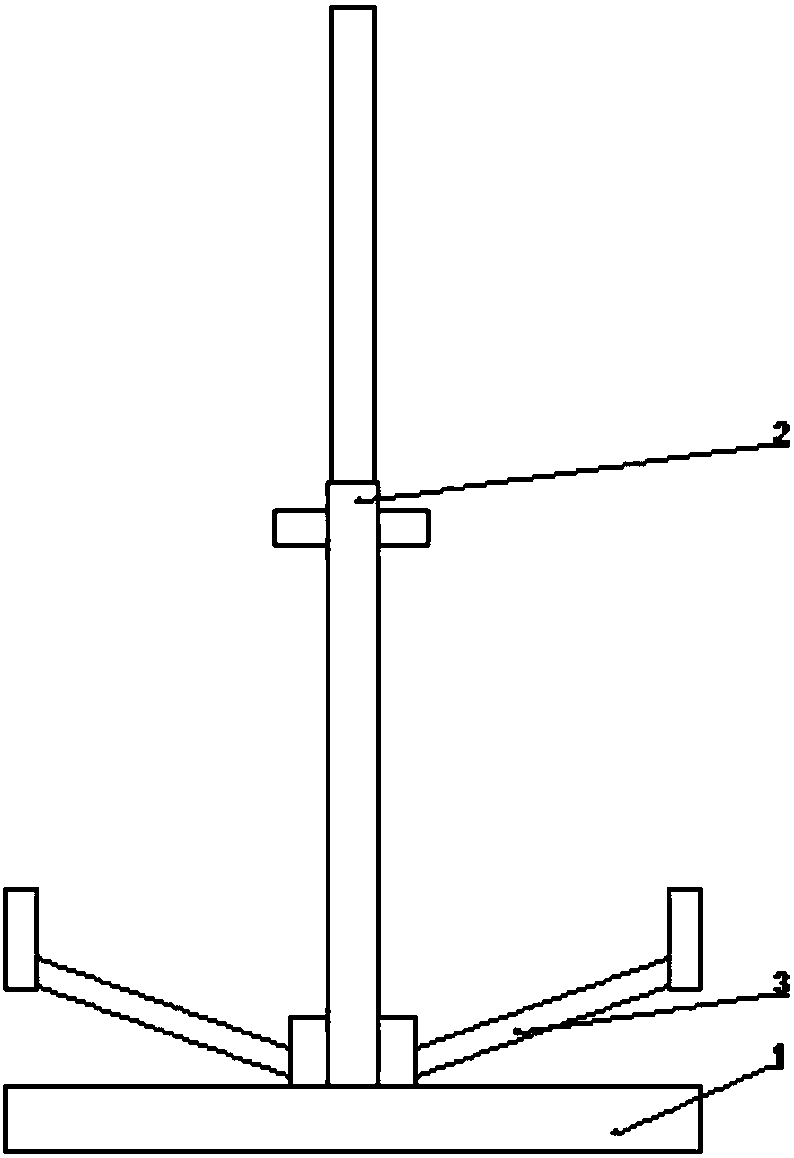

[0048] Such as Figure 2-6 A high-altitude anti-tilt steel frame structure shown includes: a supporting beam 1, a mast 2, a supporting rod 3, a supporting oblique rod 4 and a hoop rod 5, the supporting beam 1 is provided with a mast 2, and the mast 2 The lower end is connected with a supporting rod 3, the middle section of the mast 2 is provided with a supporting diagonal rod 4, and the supporting diagonal rod 4 is provided with a circumferential rod 5; one end of the supporting rod 3 is connected to one end of the supporting diagonal rod 4 The ends are connected.

[0049] The installation method of a high-altitude anti-tilt steel frame structure described in this embodiment includes construction from the inside to the outside and from the bottom to the top, and specifically includes the following steps: Step 1: Install the support beam 1, and use the crawler crane to lift the support Beam 1 is fixed by welding; step 2: install mast 2, hoist mast 2 with a crawler crane, snap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com