Steam turbine energy saving improvement structure and improvement method thereof

A technology of energy-saving transformation and steam turbine, applied in the field of machinery, can solve problems such as difficult operation, high investment, and long construction period, and achieve the effect of simple operation, low investment, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

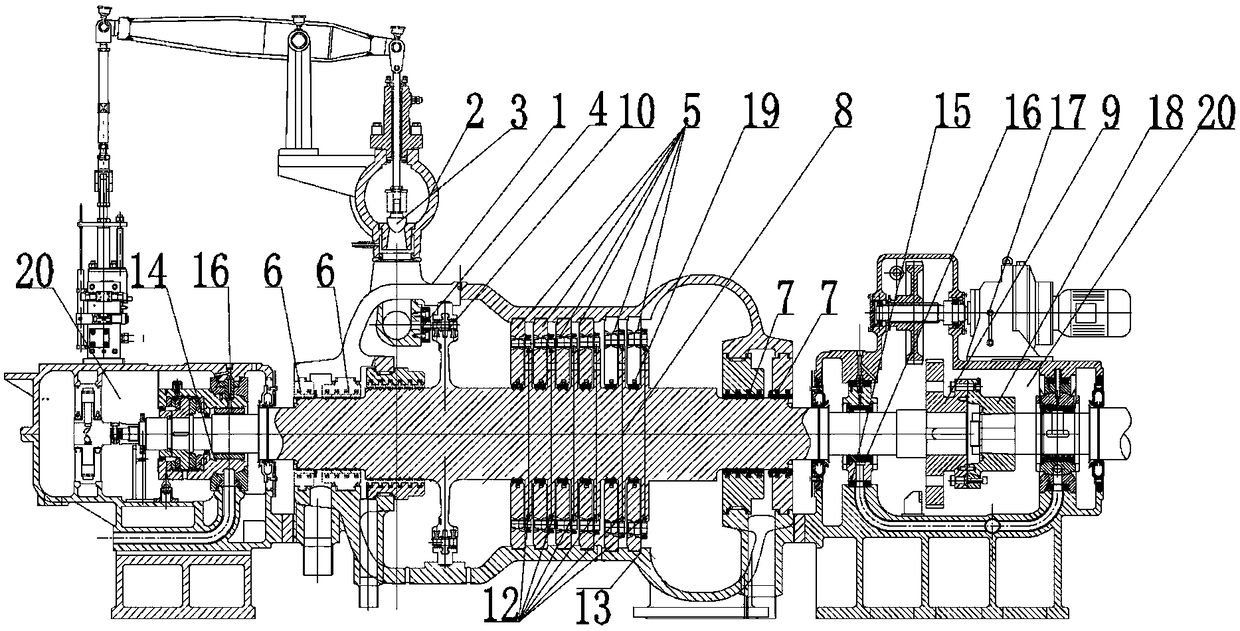

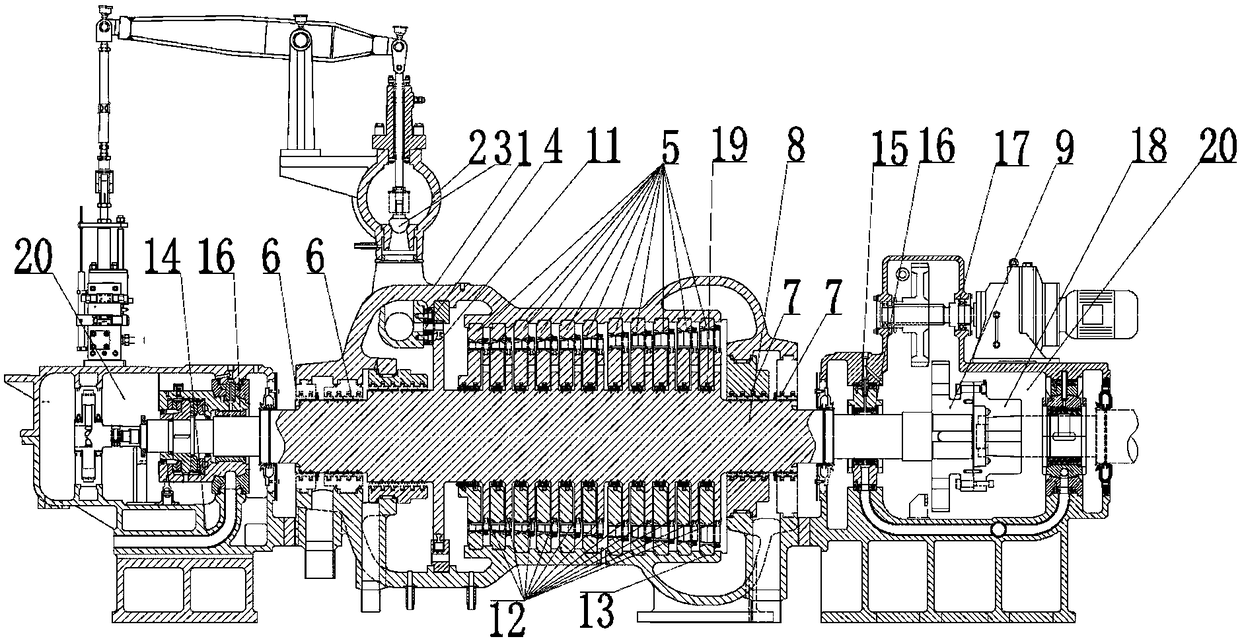

[0030] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0031] Please see attached figure 1 and attached figure 2 As shown, a steam turbine energy-saving transformation structure includes a cylinder 1, a steam chamber 2, a regulating valve 3, a nozzle group 4, a single-row regulating stage impeller 11, a pressure stage impeller 12, a multi-stage diaphragm 5, a diaphragm seal 19, a diaphragm Plate groove 13, front seat frame 14, rear seat frame 15, bearing 16, barring 17, rotor assembly 8, bearing housing 20, front steam seal 6, rear steam seal 7 and shaft coupling 9; the regulating valve 3 Installed in the steam chamber 2, the steam chamber 2 is welded on the cylinder 1; the front end and the rear end of the cylinder 1 are adapted to be installed on the front seat frame 14 and the rear seat frame respectively 15, the nozzle group 4 is fixedly installed inside the cylinder 1 by bolts, and the multi-stage pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com