Method and system for ignition coil control

A technology of ignition coil and controller, applied in ignition controller, spark ignition controller, engine ignition, etc., can solve the problems of circuit resistance fluctuation and affecting ignition coil current, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

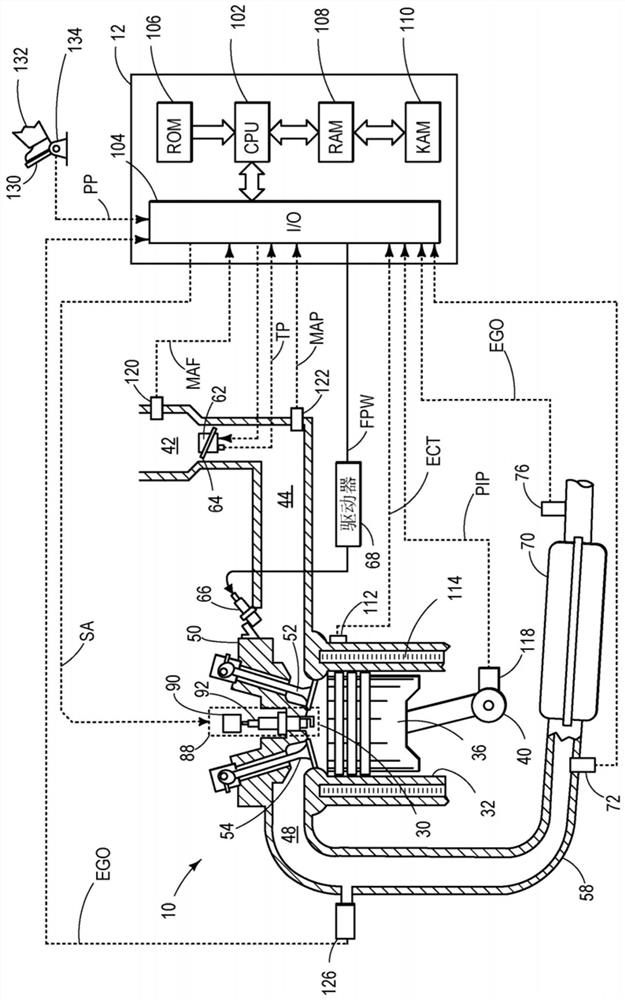

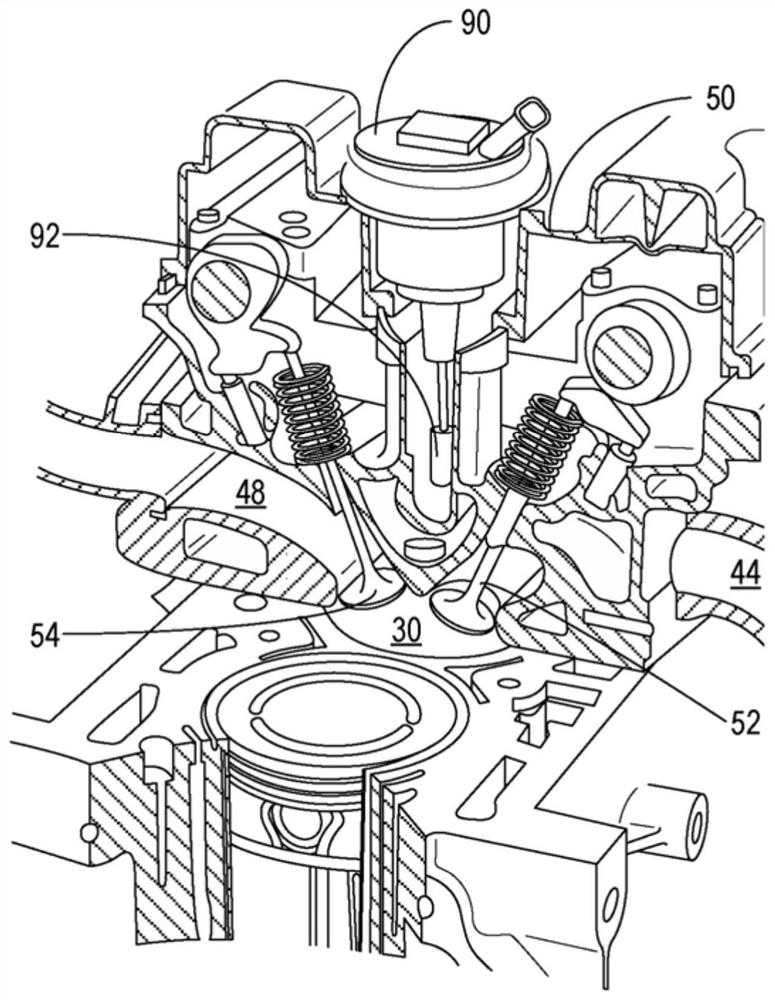

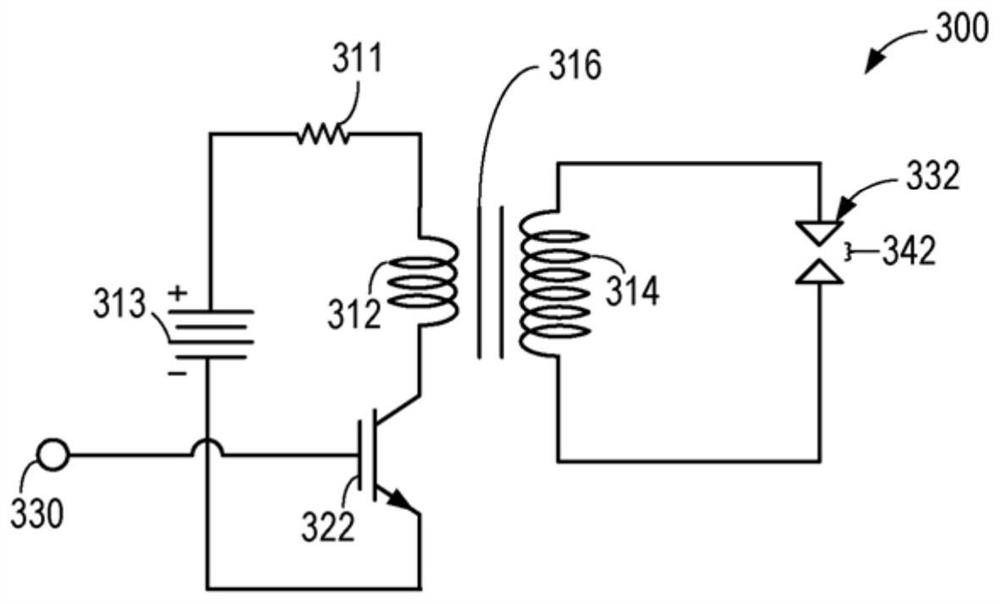

[0015] The following description relates to systems and methods for controlling current charged to an ignition coil coupled to an internal combustion engine system. exist figure 1 An example of an internal combustion engine system is shown in . figure 2 is a partial view of the engine system showing the location of the ignition system within the engine system. The ignition system may contain ignition coils and spark plugs. image 3 A simplified diagram showing the circuit of the ignition system. The circuit includes a primary coil, a battery, and a secondary coil. By coupling the primary coil to the battery for the dwell time, a charging current can be accumulated and flowed through the primary coil. The amplitude of the current depends on the ignition coil temperature. Figure 4 An example method of estimating ignition coil temperature during engine operation is shown. Figure 5 An example method of determining a dwell time based on an estimated ignition coil temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com